Technique of feeding flow in static pressure by injection pump of viscoelastic fluid

A fluid injection and viscoelastic technology, which is applied in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high vibration and easy damage to the pump, and achieve sufficient liquid supply, high efficiency, and elimination of mutual interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

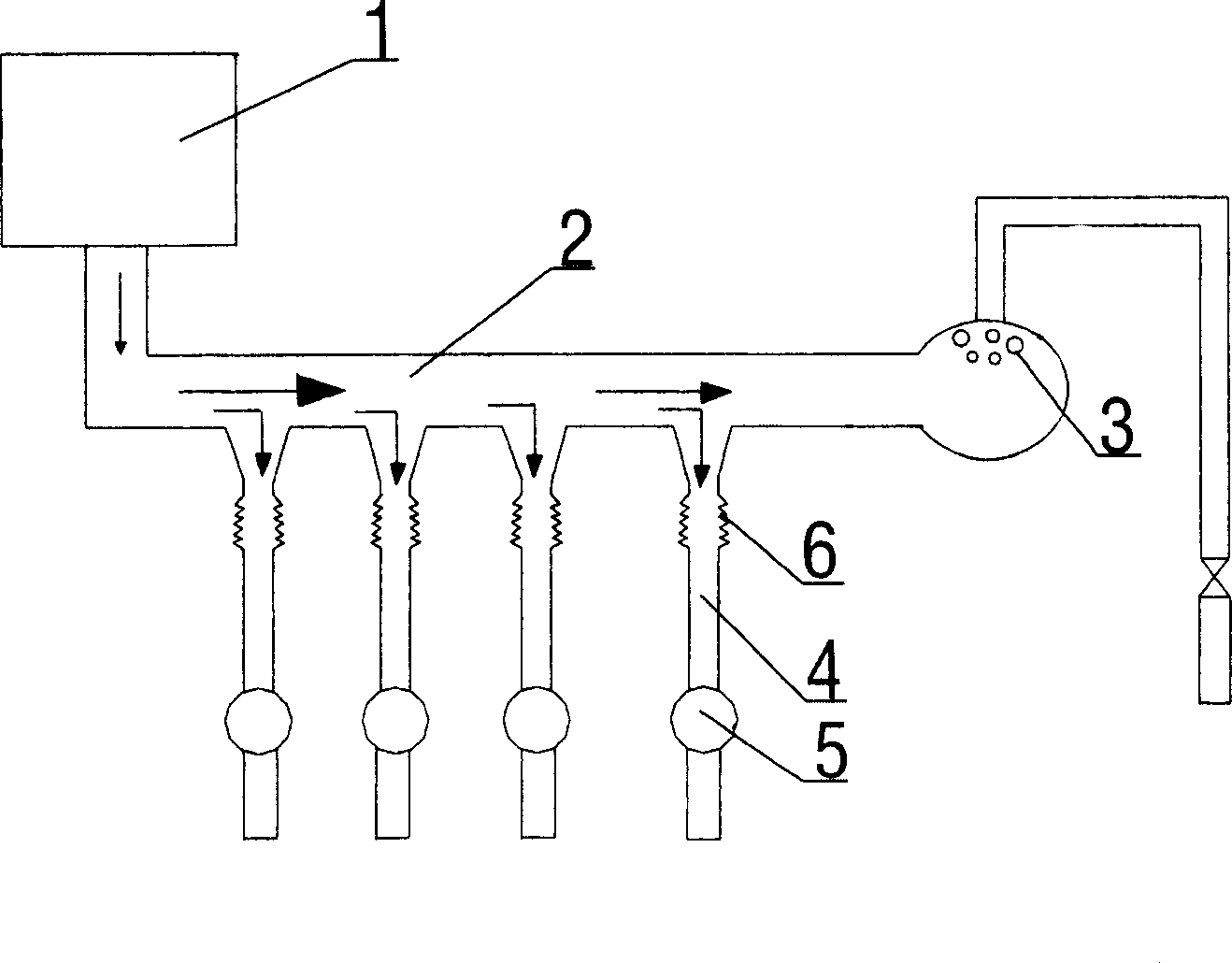

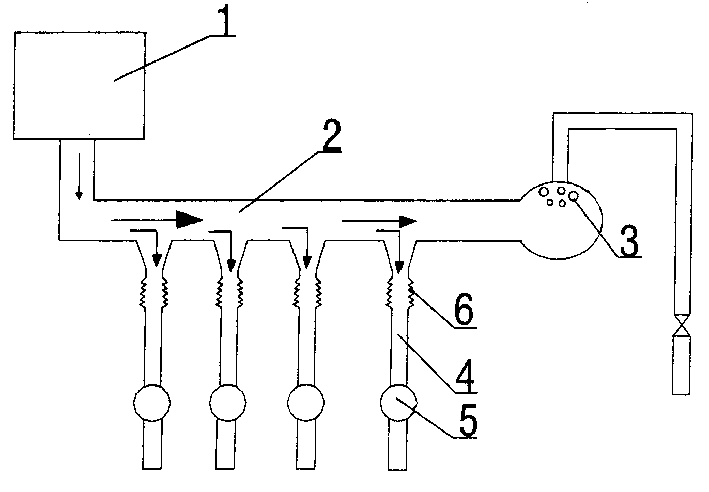

[0010] combined with figure 1 As shown, the hydrostatic liquid supply process of the viscoelastic fluid injection pump adopts a large-diameter liquid header 2, so that the liquid flow rate in the header 2 tends to zero. According to the theoretical calculation and experimental data of viscoelastic fluid mechanics, the liquid The difference between the tensile force and the normal stress produced when the header pipe 2 flows into the branch pipe 4 through the hose 6 also tends to zero; and the front end of the header pipe 2 is connected to the open container 1, so that the air bubbles in the liquid can be eliminated, The other end of the tube 2 is connected to the air-collecting bag 3, so that the viscoelastic polymer liquid flows directly from the elevated tank 1 into the manifold 2, without branch pipes, eliminating the tensile force and normal force at the branch pipes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com