Defrosting methods for double-system air-cooling refrigerator

An air-cooled refrigerator and dual-system technology, which is applied in refrigeration and liquefaction, defrosting, refrigerators, etc., can solve the problem of high energy consumption of air-cooled refrigerators and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

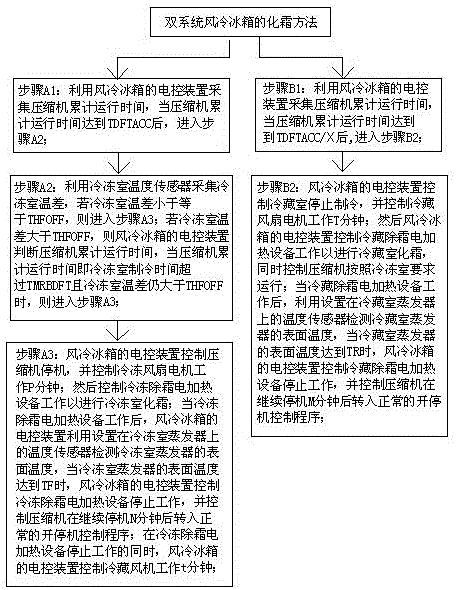

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0029] Such as figure 1 As shown, the defrosting method of the dual-system air-cooled refrigerator of the present invention includes a freezing chamber defrosting method and a cold chamber defrosting method:

[0030] The method of defrosting the freezer includes the following steps:

[0031] Step A1: Use the electronic control device of the air-cooled refrigerator to collect the cumulative running time of the compressor. When the cumulative running time of the compressor reaches TDFTACC, enter step A2; wherein, TDFTACC is the preset cumulative running cycle of the compressor. In the present invention, 4.5 Hours≤TDFTACC≤15 hours;

[0032] Step A2: Use the freezer temperature sensor to collect the difference in freezing room temperature. If the difference in freezing room temperature is less than or equal to THFOFF, go to step A3; When the accumulative operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com