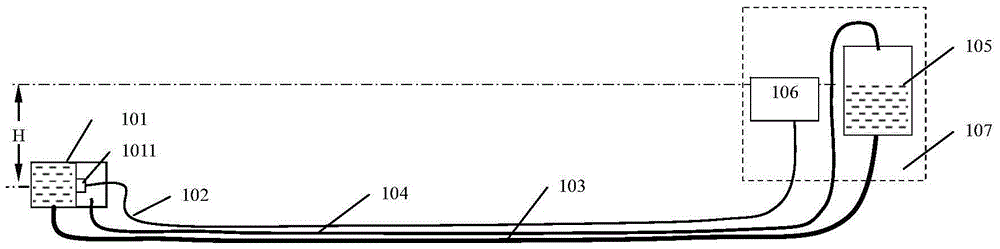

Integrated settlement monitoring apparatus based on optical fiber F-P cavity pressure sensor

A pressure sensor and subsidence monitoring technology, which is applied to measuring devices, pressure difference measurement between multiple valves, and fluid pressure measurement, etc. It can solve complex installation and debugging, cumbersome installation, and limited signal transmission distance of electrical pressure sensors. problem, to achieve the effect of simple structure, convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

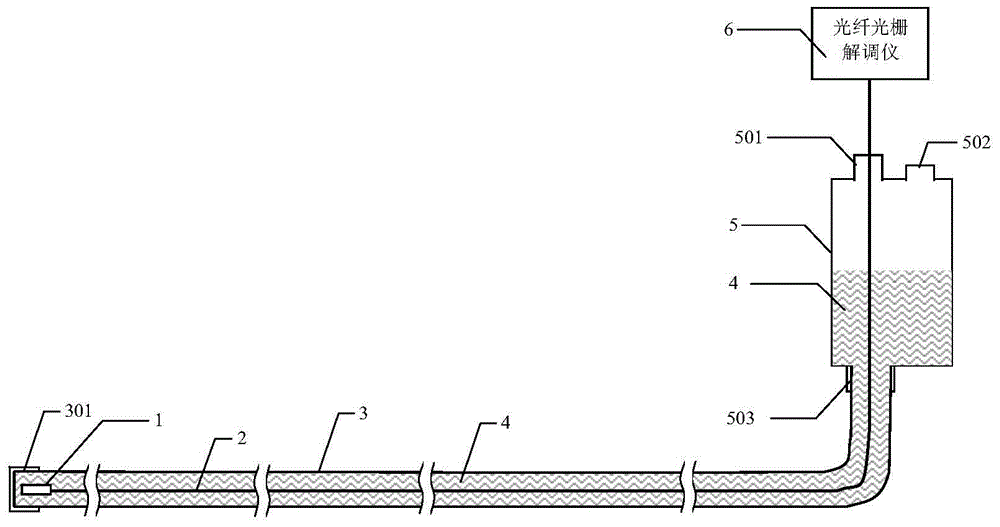

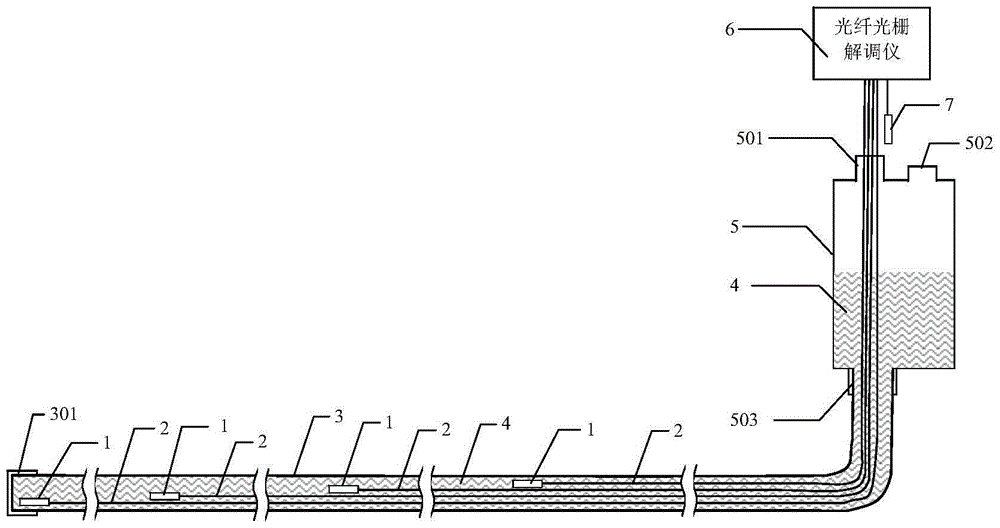

[0025] The present invention will be described below in conjunction with the drawings.

[0026] The invention relates to an integrated settlement monitoring device based on an optical fiber F-P cavity pressure sensor, and its structure is as follows figure 2 As shown, it includes a miniature optical fiber FP cavity pressure sensor 1, an optical fiber 2, a liquid pipe 3, a liquid storage container 5, and a fiber grating demodulator 6. The miniature optical fiber FP cavity pressure sensor 1 is installed in the pipe of the liquid pipe 3, and the storage The bottom end of the liquid container 5 is provided with a liquid pipe interface 503 and communicates with one end of the liquid pipe 3 through the liquid pipe interface 503, the other end of the liquid pipe 3 is sealed, and the liquid storage container 5 is provided with an optical fiber outlet hole 501 and The liquid injection hole 502 can be opened and closed. The micro-fiber FP cavity pressure sensor 1 passes through the optical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com