Absolute capacitive rotary encoder

A rotary encoder and absolute capacitance technology, which is applied in the direction of converting sensor output, instruments, and using electric/magnetic devices to transfer sensing components, etc., can solve the problems of not considering error sources and insufficient high-precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

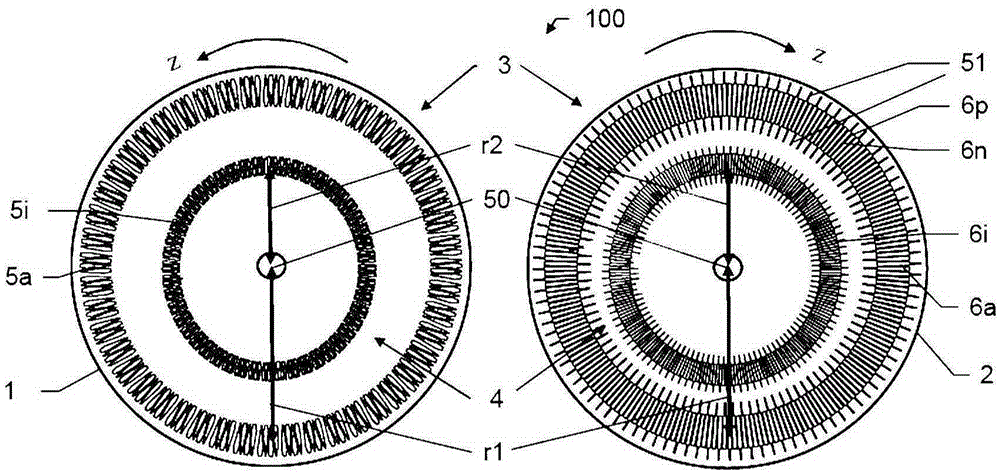

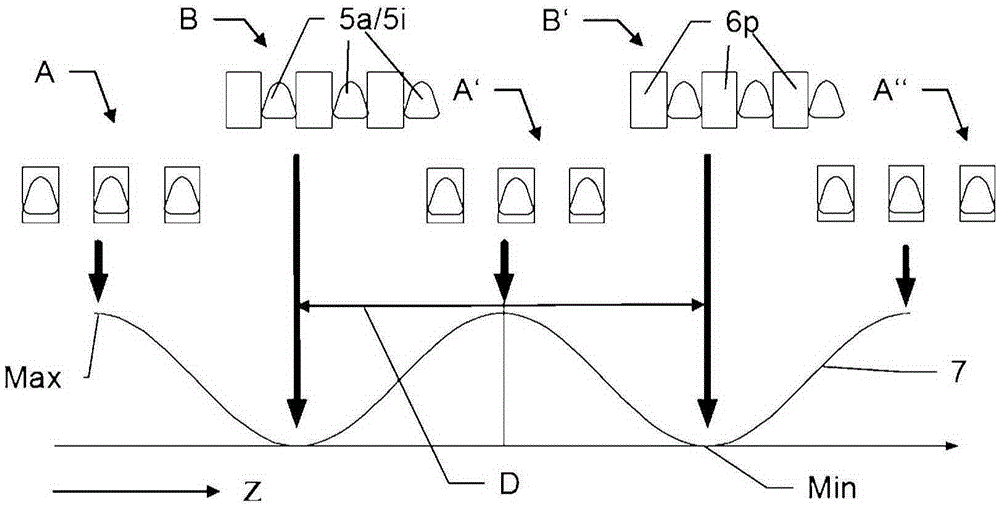

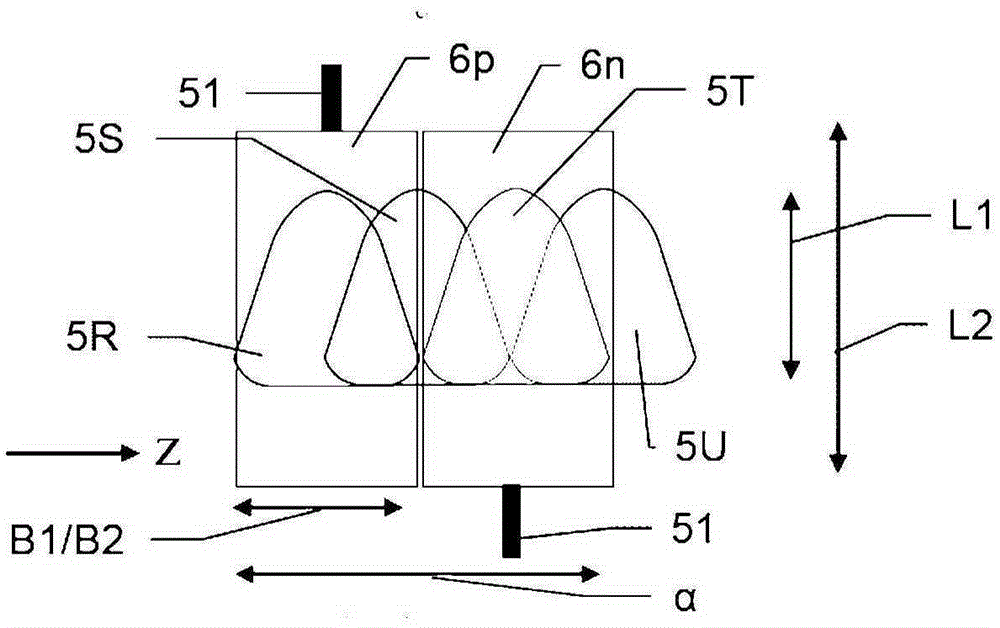

[0054] figure 1 A rotary encoder 100 according to the invention is shown comprising a first disc 1 , denoted below as stator 1 , and a second disc 2 , denoted below as rotor 2 . The stator 1 and the rotor 2 are arranged coaxially and at a distance from each other on a measuring axis 50 , rotatable relative to each other about the measuring axis 50 . However, in accordance with figure 1In the illustration of , for clarity, the rotary encoder is "folded open", i.e. both the stator 1 and the rotor 2 are in the plane of the drawing, and as a result, the facing areas of discs 1 and 2 are visible. The rotary encoder 100 has a first sensor ring 3 with: a plurality of first coupling electrodes 5a, which in this example are realized as transmitting electrodes and are arranged in a ring-shaped manner on the stator 1; Two coupling electrodes 6 a are realized in this example as receiving electrodes and are arranged in a ring-shaped manner on the rotor 2 . In addition, the rotary encode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com