Method for improving precision of quartz type dynamic automobile scale

A truck scale, quartz-type technology, applied in the field of electrical automation, can solve the problems of inconsistency of accuracy and sensitivity distribution, the maximum measurement error of the weighing instrument system cannot be effectively controlled, and the measurement error is too large, so as to reduce charging disputes, reduce errors, The effect of increasing confidence

Inactive Publication Date: 2016-06-15

GUANGZHOU XINLIUXIANG ELECTRONICS SCI & TECH CO LTD

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the process of dynamic weighing, the inconsistency of the accuracy and sensitivity distribution of the quartz load cell itself, the non-uniform straight-line driving of the measured vehicle (that is, irregular driving, such as acceleration or deceleration passing, inclined, S-shaped driving, etc.) through weighing Changes in measuring area and ambient temperature are the main objective factors that cause the maximum measurement error of the quartz truck scale system to be large (greater than ±1.5%, or even exceeding ±5%)

Under the original technical conditions, even if the high-quality imported quartz weighing sensor is used, the maximum measurement error of the weighing instrument system cannot be effectively controlled within ±2.0%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

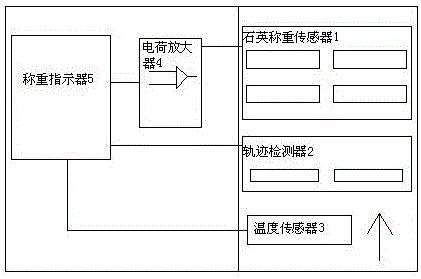

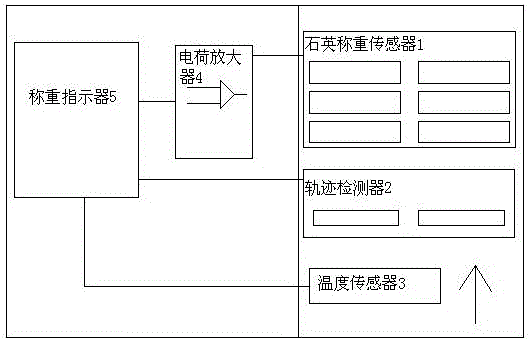

[0056] like figure 2 As shown, three rows of quartz load cells are laid in this embodiment.

Embodiment 2

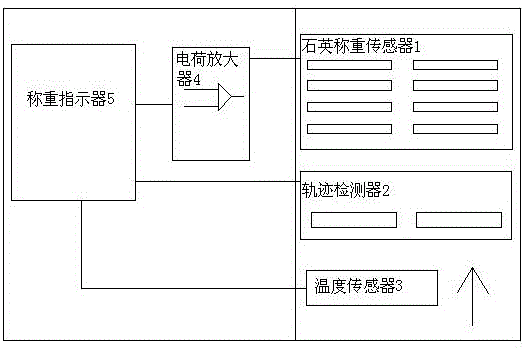

[0058] like image 3 As shown, four rows of quartz load cells are laid in this embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method for improving the precision of a quartz-type dynamic truck scale, the invention relates to the technical field of electrical automation; it improves the quartz-type dynamic truck scale through the data read by a weighing indicator, a charge amplifier, a track detector, a quartz load cell, and a temperature sensor. Vehicle scale accuracy; the quartz weighing sensor is connected with the charge amplifier, and the charge amplifier is connected with the weighing indicator; the track detector and the temperature sensor are all connected with the weighing indicator; the weighing indicator is connected with the weighing indicator Charge amplifier connection; improve the measurement accuracy of the quartz-type dynamic truck scale, the highest measurement accuracy of the weighing instrument system can reach ±1.0%, at the same time, improve the confidence, reliability and stability of the quartz-type dynamic truck scale; Charge disputes caused by balance errors.

Description

technical field [0001] The invention relates to the technical field of electric automation, in particular to a method for improving the precision of a quartz dynamic truck scale. Background technique [0002] The quartz load cell bears the gravity of the tires of the driving vehicle and generates a charge signal. The signal is amplified, sorted and converted into a voltage signal, and then the total weight of the vehicle is calculated after A / D conversion. In the process of dynamic weighing, the inconsistency of the accuracy and sensitivity distribution of the quartz load cell itself, the non-uniform straight-line driving of the measured vehicle (that is, irregular driving, such as acceleration or deceleration passing, inclined, S-shaped driving, etc.) through weighing Changes in measuring area and ambient temperature are the main objective factors that cause the maximum measurement error of the quartz truck weighing system to be large (greater than ±1.5%, even exceeding ±5%...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01G19/03G01G23/01

CPCG01G19/035G01G23/01

Inventor 刘宁春胡会如

Owner GUANGZHOU XINLIUXIANG ELECTRONICS SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com