Indicating material for detecting freshness of foods via carbon dioxide, and preparation method of indicating material

A carbon dioxide and freshness technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of inconvenient use and promotion alone, and achieve easy promotion and process The effect of simple operation and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

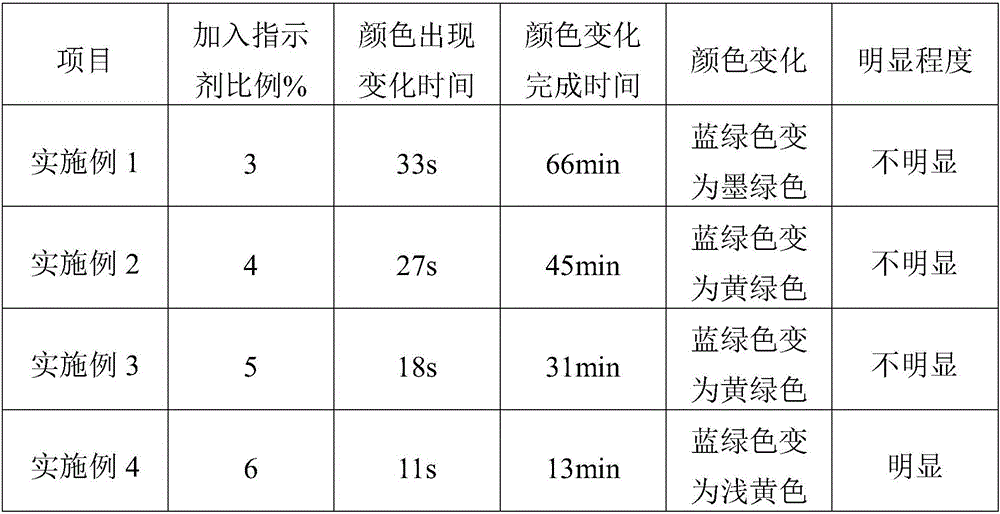

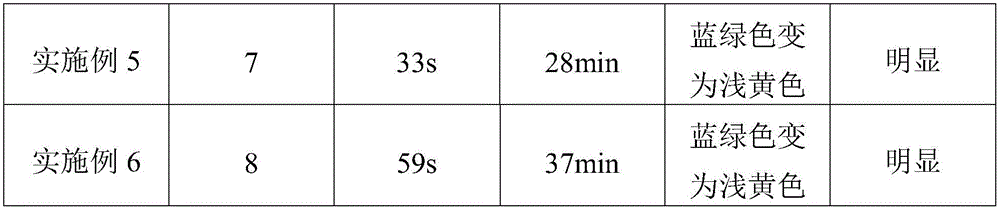

Examples

Embodiment 1

[0035] A method for preparing an indicator material for detecting food freshness through carbon dioxide, comprising the steps of:

[0036] 1. In terms of mass percentage, add 8% gelatin to 92% deionized water, swell at room temperature for 15 minutes, then carry out magnetic stirring at a stirring speed of 200r / min, heat in a water bath at 50°C, and obtain film solution A after 20 minutes

[0037] 2. According to the mass percentage, mix 4% starch, 0.05% calcium hydroxide, 0.5% glycerin, and deionized water as the balance, and carry out magnetic stirring at a stirring speed of 200r / min, heating in a water bath at 60°C, after 20min , to obtain membrane solution B.

[0038] 3. In terms of mass percentage, add 2% polyvinyl alcohol into 98% deionized water, perform magnetic stirring at a stirring speed of 200 r / min, heat in a water bath at 80° C., and obtain film liquid C after 20 minutes.

[0039] 4. Dissolve methyl red powder and bromothymol blue powder in absolute ethanol resp...

Embodiment 2

[0043] A method for preparing an indicator material for detecting food freshness through carbon dioxide, comprising the steps of:

[0044] 1. In terms of mass percentage, add 9% gelatin to 91% deionized water, swell at room temperature for 20 minutes, then carry out magnetic stirring at a stirring speed of 200r / min, heat in a water bath at 55°C, and obtain film solution A after 25 minutes

[0045] 2. According to the mass percentage, mix 5% starch, 0.075% calcium hydroxide, 1% glycerin, and deionized water as the balance, and carry out magnetic stirring at a stirring speed of 200r / min, heating in a water bath at 70°C, and after 25min , to obtain membrane solution B.

[0046] 3. In terms of mass percentage, add 3% polyvinyl alcohol into 97% deionized water, perform magnetic stirring at a stirring speed of 200 r / min, heat in a water bath at 85° C., and obtain membrane solution C after 25 minutes.

[0047] 4. Dissolve methyl red powder and bromothymol blue powder in absolute ethan...

Embodiment 3

[0051] A method for preparing an indicator material for detecting food freshness through carbon dioxide, comprising the steps of:

[0052] 1. In terms of mass percentage, add 9.5% gelatin to 90.5% deionized water, swell at room temperature for 25 minutes, then carry out magnetic stirring at a stirring speed of 200r / min, heat in a water bath at 58°C, and obtain film solution A after 27 minutes

[0053] 2. According to the mass percentage, mix 5.5% starch, 0.09% calcium hydroxide, 1.5% glycerin, and deionized water as the balance, and carry out magnetic stirring at a stirring speed of 200r / min, heating in a water bath at 75°C, and after 27min , to obtain membrane solution B.

[0054] 3. In terms of mass percentage, add 3.5% polyvinyl alcohol into 96.5% deionized water, perform magnetic stirring at a stirring speed of 200 r / min, heat in a water bath at 87° C., and obtain film solution C after 27 minutes.

[0055] 4. Dissolve methyl red powder and bromothymol blue powder in absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com