Thin lens

A lens and curved surface technology, which is applied in the field of lighting lenses, can solve the problems of light loss, simple light type, and inability to mix light evenly with LED lights, so as to reduce light loss and improve light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

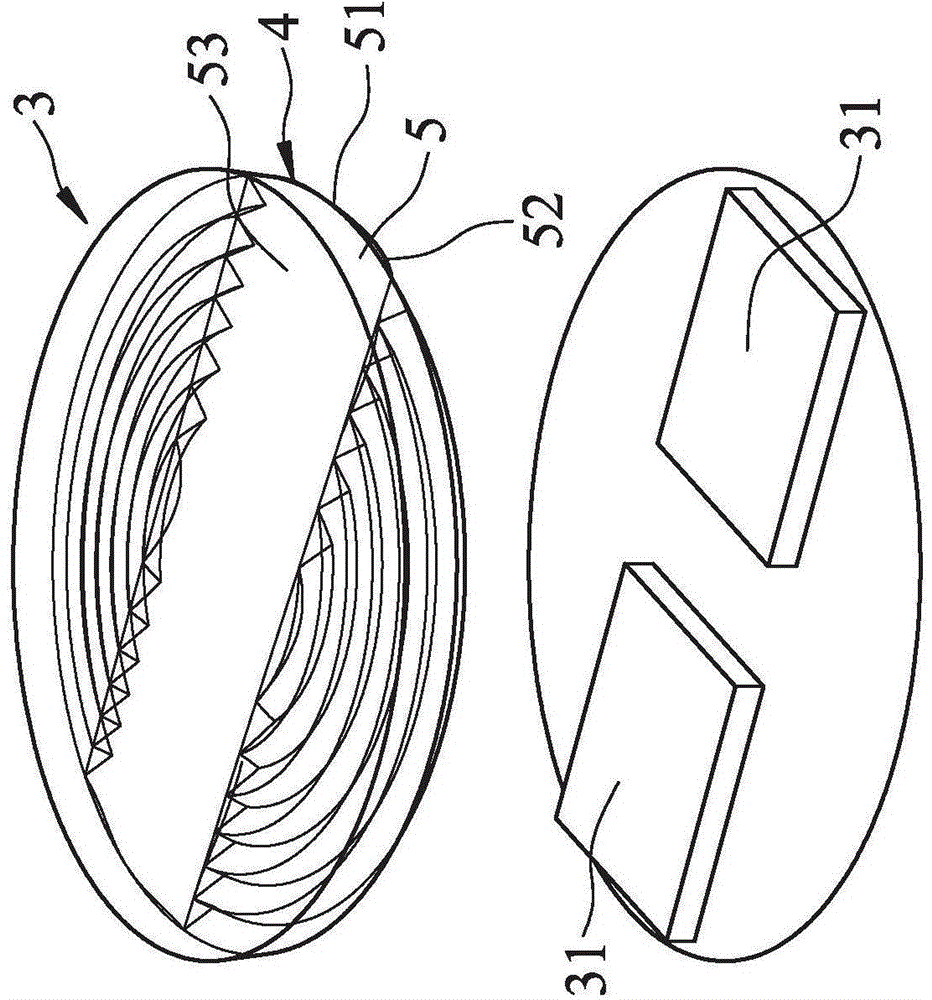

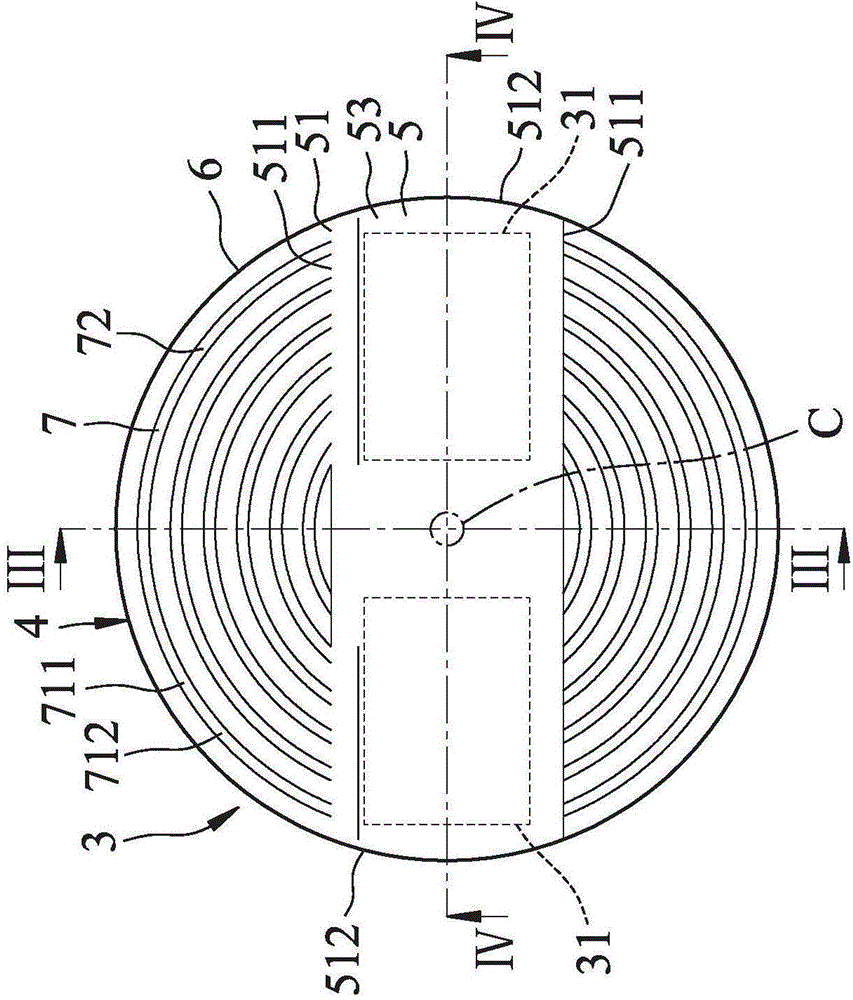

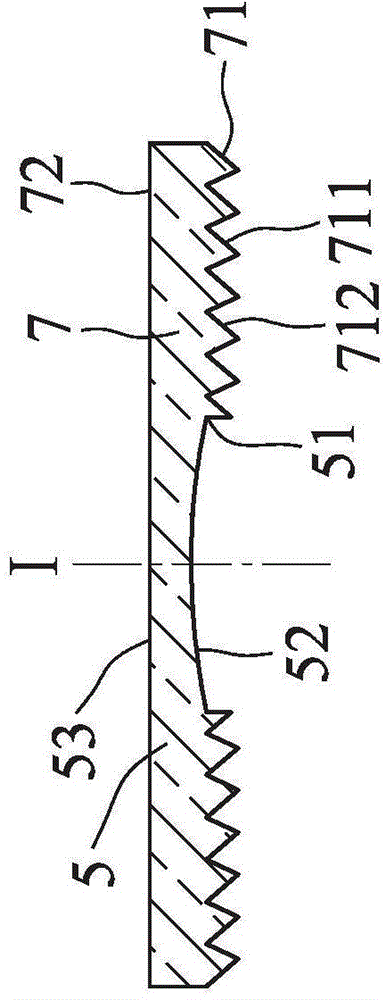

[0047] refer to figure 1 , figure 2 , image 3 and Figure 4 , a first embodiment of the thinning lens of the present invention is suitable for a lighting device 3 of a portable electronic device such as a mobile phone or a tablet computer, the lighting device 3 has a plurality of LED lamps 31 and the thinning lens 4, In this embodiment, the number of LED lamps 31 in the lighting device 3 is two and have white and yellow light emitting color temperatures respectively. The LED lamps 31 are matched with each other to achieve various lighting effects. The thinning lens 4 is arranged in front of the LED lamps 31, and includes a curved surface 5 including an outer contour 51, an outer peripheral edge 6 surrounding the curved surface 5, and a curved surface 5 and the outer peripheral edge 6. Between the tooth-like lines 7.

[0048] The curved portion 5 is located at the center of the thinned lens 4 , and the outer contour 51 of the curved portion 5 is non-circular and covers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com