A shipping device and shipping method for a cargo lane of an automatic vending machine

A technology for automatic vending machines and delivery devices, which is applied in the direction of handling coins or valuable banknotes, instruments, etc., which can solve the problems of complex overall structure, large gear box volume, and increased maintenance costs, and achieve stable transmission, small size, and low cost. The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

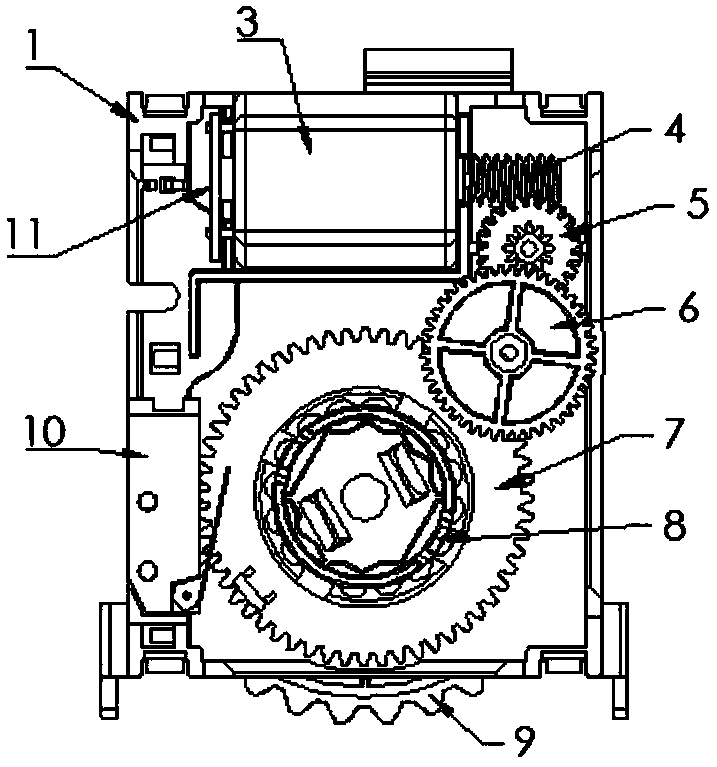

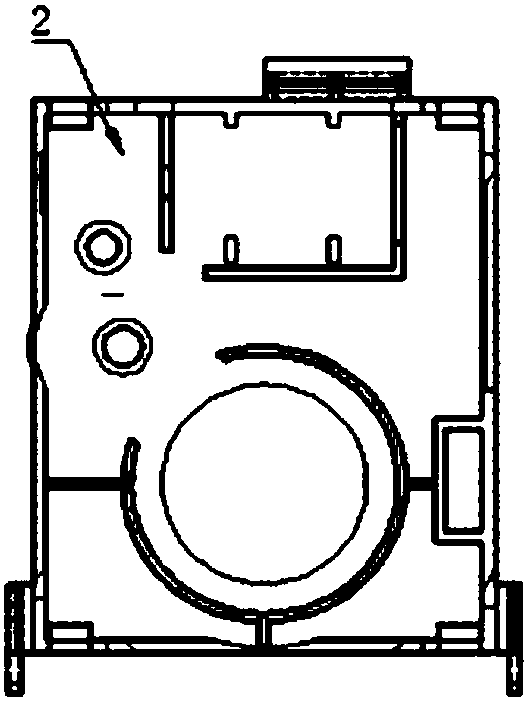

[0041] Example 1: Single Gear Box

[0042] Such as Figure 1~5 As shown, a delivery device for an automatic vending machine aisle provided by the present invention includes a drive motor 3, a worm 4, a worm gear 5, a cylindrical gear 6, an output gear 7, a circuit board 11, a main control board and a blocking plate; The motor shaft of the drive motor 3 is connected with the worm 4, the worm 4 meshes with the worm wheel 5, the coaxial gear on the worm wheel 5 meshes with the cylindrical gear 6, and the cylindrical gear 6 The coaxial gear meshes with the output gear 7, and a gear connector 8 is installed on the output gear 7; the main control board is connected with the circuit board 11, and the circuit board 11 is connected with the micro switch and The drive motor 3 is connected, and the micro switch is provided with a shrapnel 10; the plane of the output gear 7 is provided with a catch, and the positions of the shrapnel 10 and the catch meet: the catch and the catch The rot...

Embodiment 2

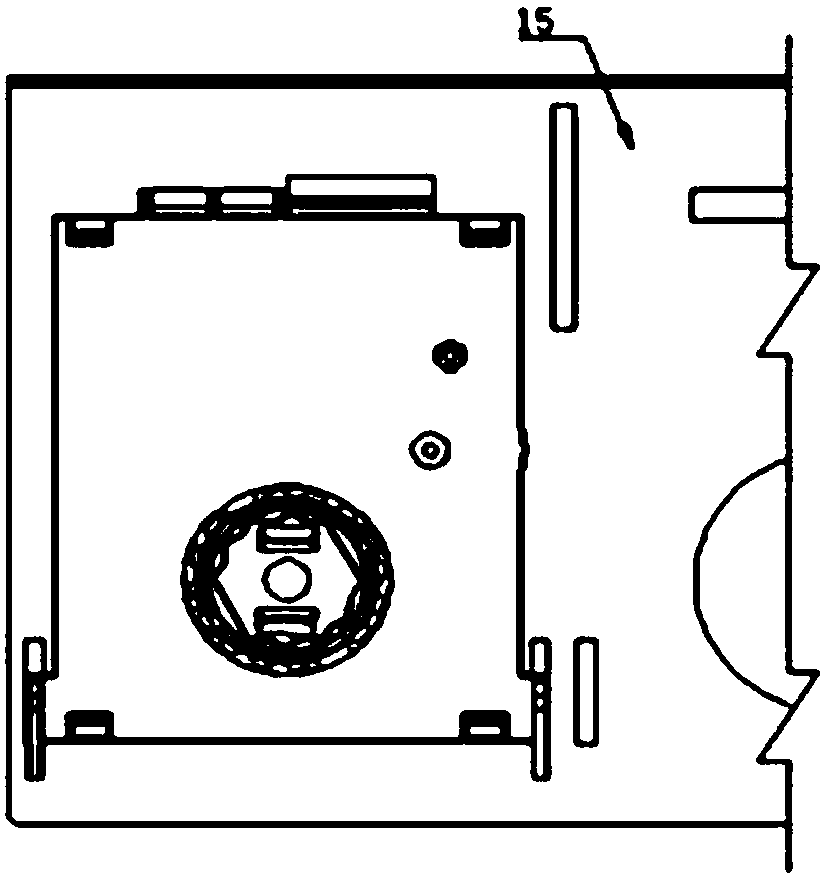

[0048] Example 2: Double gear box

[0049] Such as Figure 6-9 As shown, on the basis of Embodiment 1, Embodiment 2 mainly adds the following structure: the cylindrical gear 6 meshes with the cylindrical gear I6a, the coaxial gear on the cylindrical gear I6a meshes with the output gear I7a, and the output The gear I7a is connected with the gear connecting part 8 , and the gear connecting part 8 is connected with the spring fixing part 12 .

[0050] The delivery device of the aisle of the automatic vending machine also includes a double gear box and a double gear box mounting plate 16, and the double gear box is fixed on the double gear box mounting plate 16 through hook angles and buckles. The gear box includes a double gear box cover 14 and a double gear box bottom cover 13, the double gear box cover 14 is closed on the double gear box bottom cover 13 by a buckle cover, the drive motor 3, the micro switch , worm screw 4, worm gear 5, output gear 7, spur gear 6, output gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com