Manual maintenance switch with secondary unlocking structure and its unlocking method

A technology for manual maintenance of switches and handles, which is applied to the parts of connecting devices, devices that prevent contact with live contacts, electrical components, etc. the effect of pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

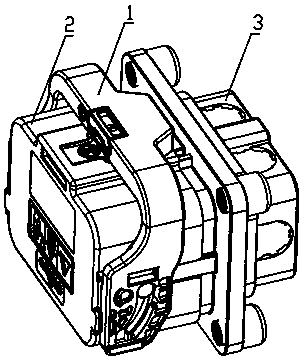

[0034] The invention discloses an electrical connector with a secondary unlocking structure, such as figure 1 , figure 2 As shown, it includes a connector plug 2 and a connector socket 3 mated with each other, and a primary locking mechanism for strengthening the fixing of the two. The primary locking mechanism is a handle 1 straddling the two sides of the connector plug 2, and the handle pivots around the connector plug 2 to control the connection between the connector plug 2 and the connector socket. 3 moves axially, and the connector plug 2 and the connector socket 3 are completely closed or separated in the axial direction through the opening and closing of the secondary locking mechanism.

[0035] The connector plug 2 and the connector socket 3 have three position states:

[0036] In the first locked state, the handle 1 locks the connector plug 2 and the connector socket 3, and both are completely closed, so that the power terminals and signal terminals between the two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com