Transparent cover board capable of being wiped

A transparent cover and tempered glass technology, which is applied in the installation of ground cables, electrical components, cables, etc., can solve the problems of dew condensation, opacity, opacity of transparent cover, etc., so as to improve safety, toughness and attachment Focus on the effect of avoiding rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

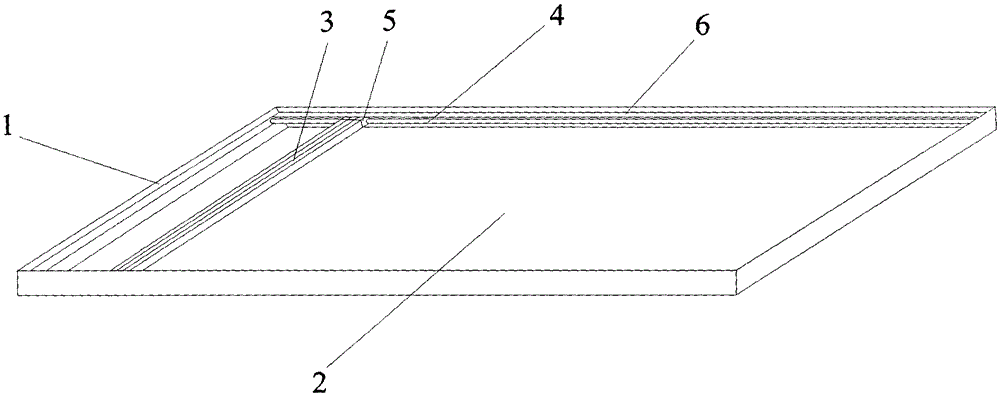

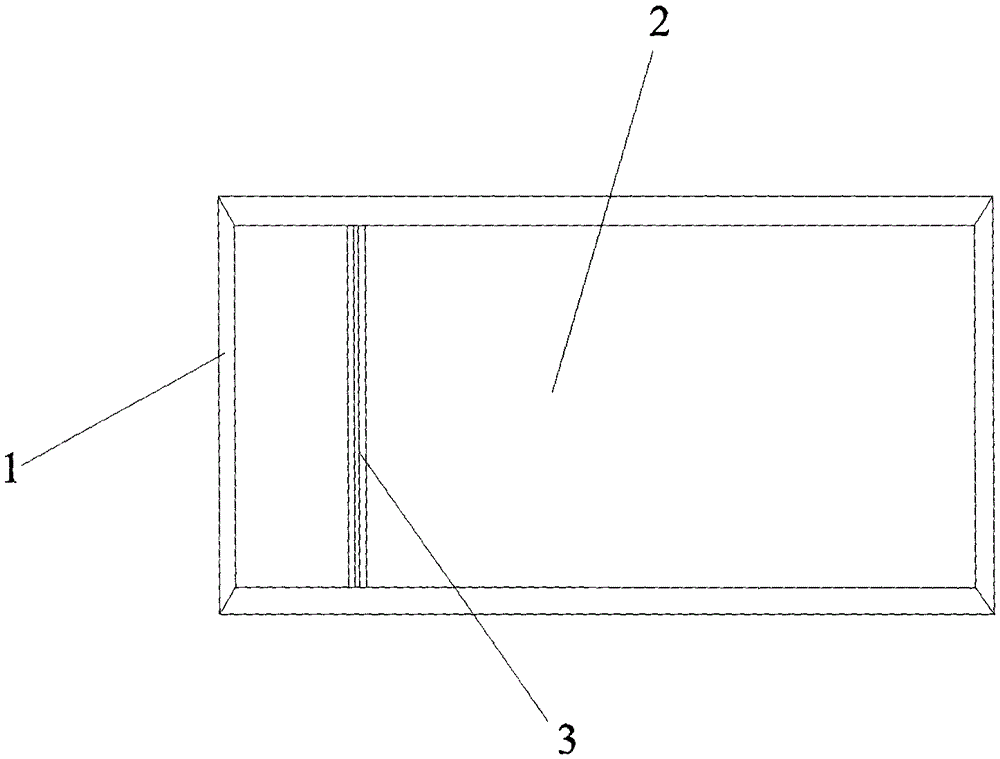

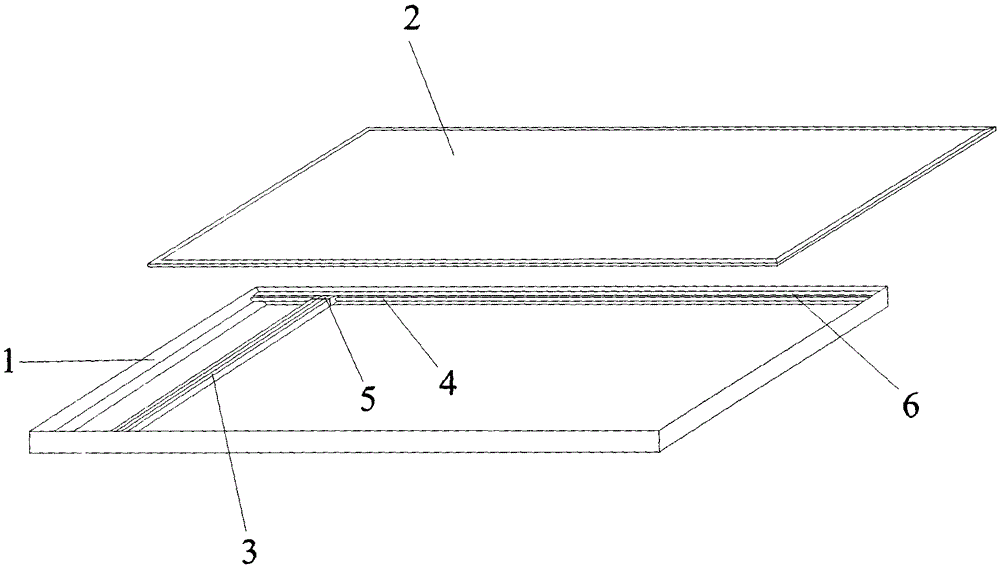

[0027] See Figure 1-Figure 3 , figure 1 It is a schematic diagram of the overall structure of the wipeable transparent cover in Example 1 of the present invention; figure 2 It is a top view structure diagram of the wipeable transparent cover plate in Embodiment 1 of the present invention; image 3 It is an exploded structure diagram of the wipeable transparent cover plate in Embodiment 1 of the present invention.

[0028] The wipeable transparent cover plate provided in this embodiment includes tempered glass 2 and bracket 1, and tempered glass 2 is mounted on bracket 1; bracket 1 includes guide rail 4 and cross arm 3, and cross arm 3 is slidably arranged on guide rail 4; The pole 3 is provided with a wiping mechanism (not shown in the figure), and the wiping mechanism is attached to the lower surface of the tempered glass 2; the cross arm 3 is provided with a permanent magnet (not shown in the figure). The permanent magnet can be a whole permanent magnet; the permanent m...

Embodiment 2

[0042]The wipeable transparent cover provided by this embodiment includes tempered glass and a bracket, and the tempered glass is mounted on the bracket; the bracket includes a guide rail and a cross arm, and the cross arm is slidably arranged on the guide rail; the cross arm is provided with The wiping mechanism is attached to the lower surface of the toughened glass; the cross arm is provided with a permanent magnet.

[0043] There are slide holes on the cross arm, and the cross arm is sleeved on the guide rail through the slide hole, and the cross arm can slide on the guide rail through the slide hole. As long as the guide rail and the sliding hole are smooth enough, the frictional resistance between the two will be relatively small, and the cross arm can also slide smoothly on the guide rail.

[0044] Gaskets are also arranged on the bracket, and the gaskets are slightly higher than the cross-arm in the vertical direction. It will block the sliding of the cross arm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com