Die and method for molding composite material of semi-closed cavity gridding stressed-skin structure

A technology of composite materials and forming molds, which is applied in the field of forming molds, can solve the problems that structural parts cannot be formed, and achieve the effects of light weight, strong impact resistance, and high grid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

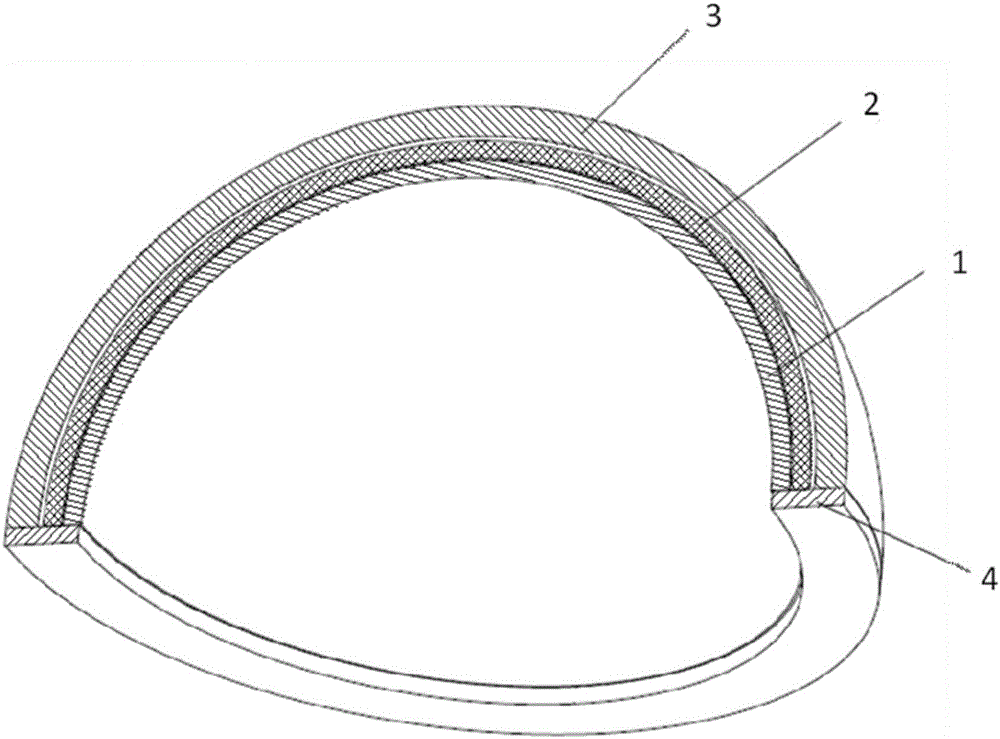

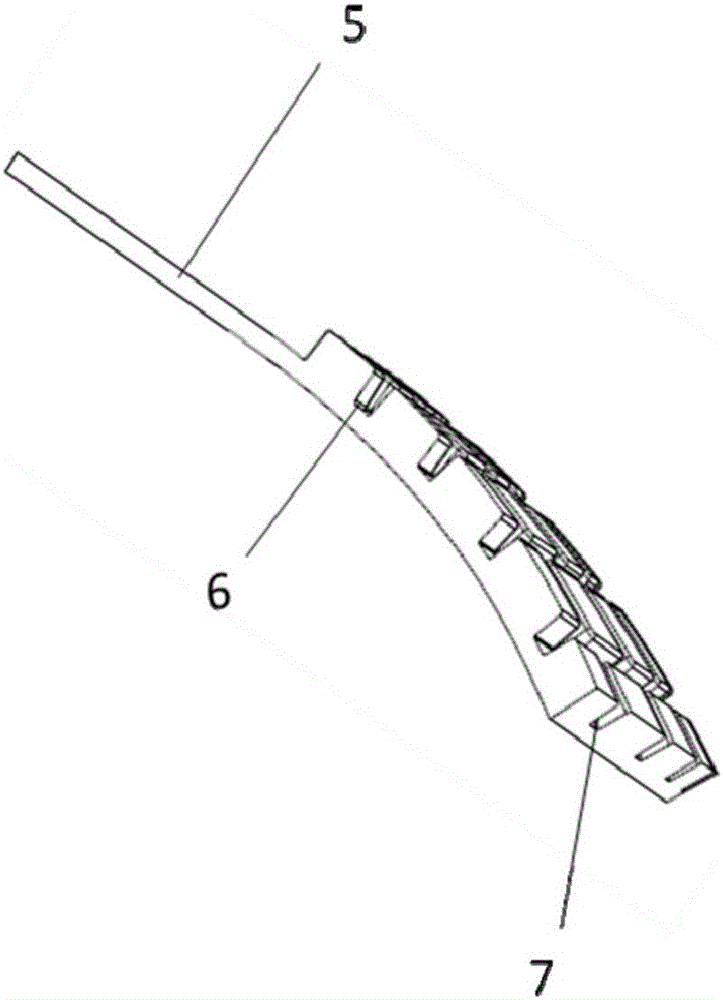

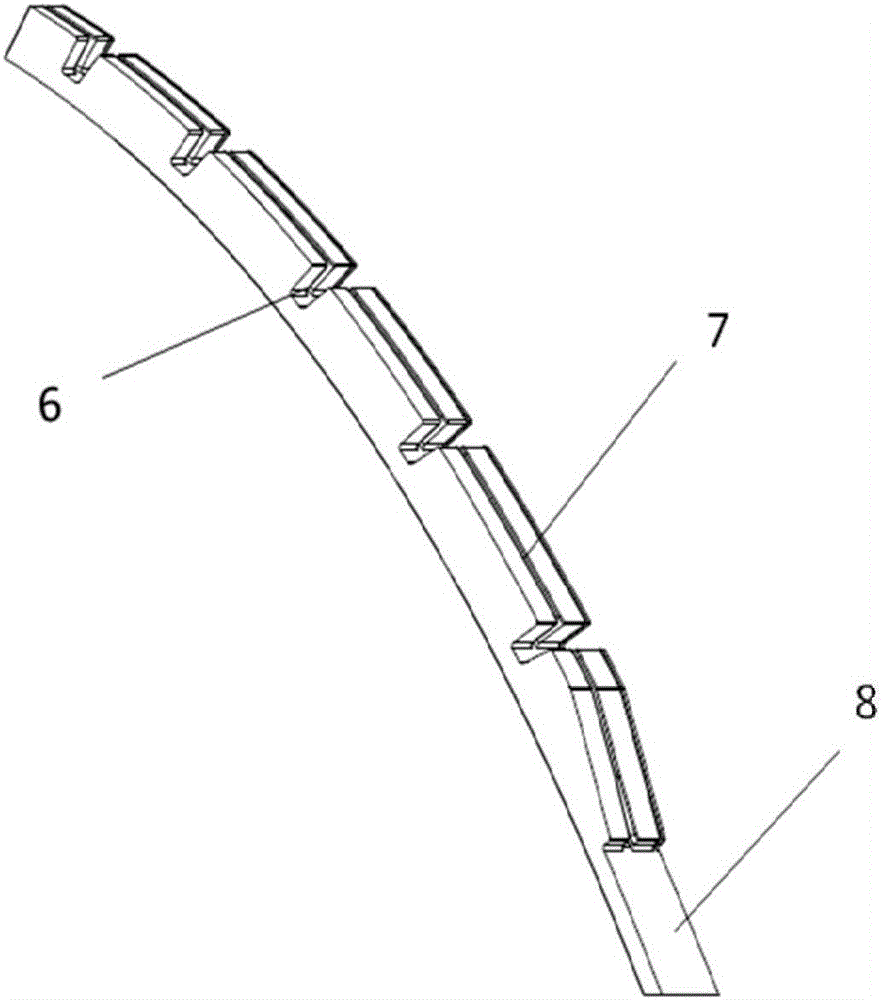

[0040] Such as figure 1 As shown, a semi-closed cavity grid-skin structure composite material forming mold includes a core mold lining 1, a male mold 2, an outer female mold 3 and a lower pressure ring 4. The mandrel lining 1 is a curved shell with an open lower end and protruding outwards, such as a hemispherical shell or a semi-ellipsoidal shell, which is consistent with the shape of the semi-closed cavity component to be produced. In this embodiment, it is a hemispherical shell, the male mold 2 is wrapped outside the mandrel lining 1, and the inner surface of the male mold 2 is bonded to the outer surface of the mandrel lining 1. The male mold 2 includes 8 split mold pieces, and all the split mold pieces are spliced into a hemispherical shell; in this embodiment, it is divided into 4 parts along the meridian and 2 parts along the latitude. The male mold 2 is provided with protrusions between the latitudes a ° ~ b °, a is 20 ~ 30, b is 70 ~ 85, rib grooves are formed betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com