Automatic air exhaust device and method for packaging bags

A technology for automatic exhaust and packaging bags, applied in packaging and other directions, can solve the problems of increasing the risk of packaging bag damage, hidden dangers in medical safety, and volume expansion of packaging bags, so as to improve the efficiency of exhaust operation, ensure exhaust quality, and improve the structure of the device. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

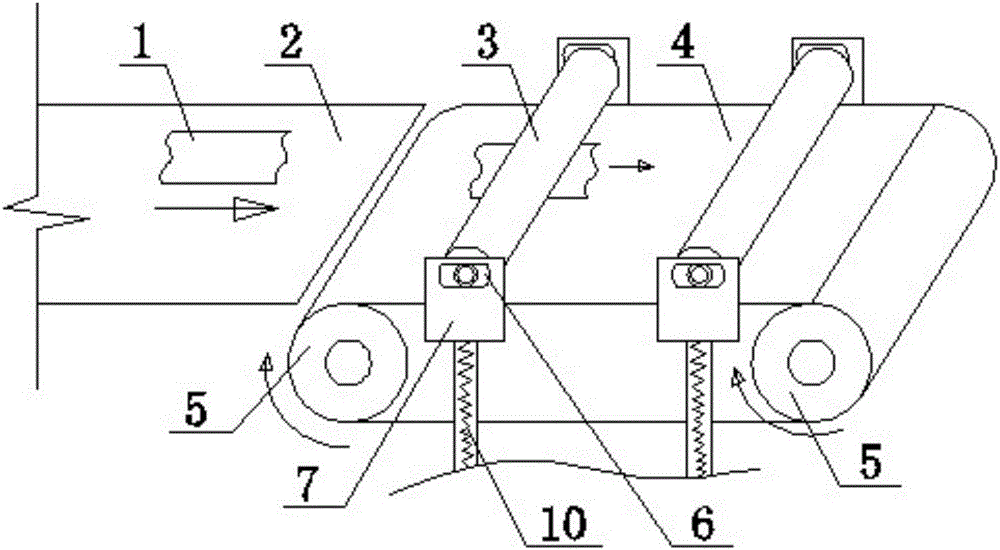

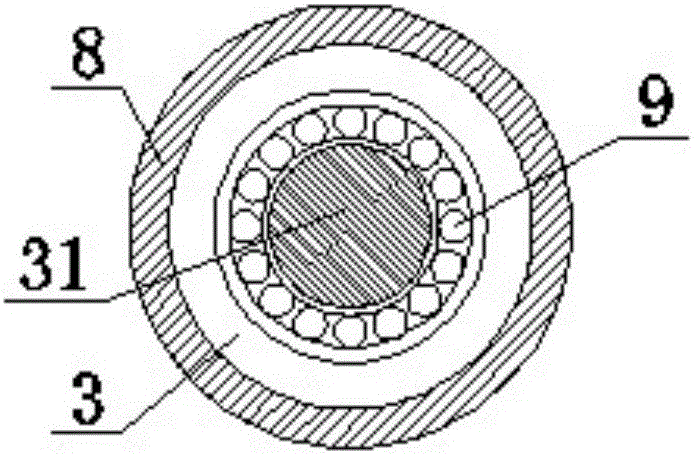

[0022] Such as figure 1 The shown packaging bag automatic exhaust device mainly includes an exhaust drum 3, a belt 4 and a bracket 7, and the bracket 7 is fixedly installed on opposite sides of the belt 4, and guide grooves 6 are set on the bracket 7, and the belt 4 passes through The pulley 5 is supported and moves synchronously with the rotation of the pulley 5. The guide groove 6 is a straight guide groove and is arranged parallel to the belt 4; 6 cooperates and straddles on the belt 4.

[0023] When using the above-mentioned device to perform exhaust treatment on the packaging bag 1 to be exhausted, a motor or other power device can be used to drive the pulley 5 to rotate, so that the belt 4 can move synchronously with the rotation of the pulley 5, and can pass through the conveyor belt. 2. Continuously put the packaging bag 1 into the belt 4. The packaging bag 1 on the horizontal plane of the belt 4 passes under the exhaust roller 3 sequentially with the movement of the...

Embodiment approach 2

[0026] Such as figure 1 As shown, a tension spring 10 is connected to the exhaust cylinder 3, and one end of the tension spring 10 is flexibly connected to the cylinder shaft 31, so that the tension spring 10 will not be wound on the cylinder shaft 31 as the cylinder shaft 31 rotates. The other end of the extension spring 10 can be fixed on the bracket 7, or can be fixed on other fixed fixtures. For example, when the device and the packaging machine form an assembly line, the other end of the extension spring 10 can be fixed according to the site conditions. fixed on the packaging machine. Others are the same as Embodiment 1.

[0027] The movement elasticity and stability of the exhaust roller 3 can be increased by setting the tension spring 10, so that the contact between the exhaust roller 3 and the packaging bag 1 is good, and the rolling pressure of the exhaust roller 3 on the packaging bag 1 is guaranteed to be more stable and uniform. Thereby, it is beneficial to impro...

Embodiment approach 3

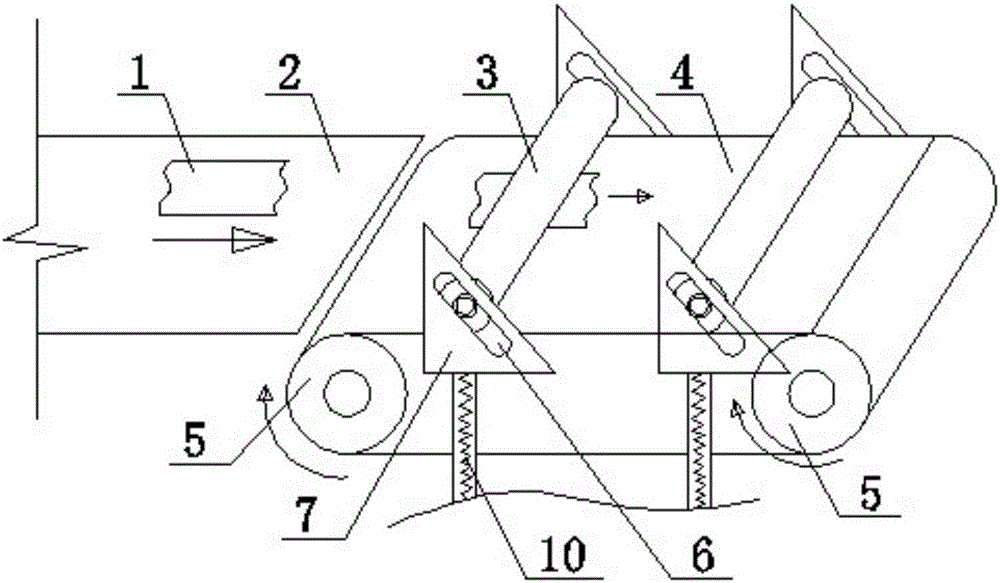

[0029] Such as image 3 As shown, the guide groove 6 is a straight guide groove and is arranged obliquely relative to the belt 4 . Others are the same as Embodiment 1.

[0030] When the packaging bag 1 on the horizontal plane of the belt 4 passes under the exhaust roller 3 sequentially with the movement of the belt 4, due to a certain friction force between the packaging bag 1 and the exhaust roller 3, the exhaust roller 3 While rotating relative to the packaging bag 1, there is also a movement trend of climbing along the guide groove 6 relative to the packaging bag 1. However, since the guide groove 6 is arranged obliquely relative to the belt 4, the exhaust drum 3 can move on its own. Under the action of gravity, the exhaust roller 3 is prevented from climbing up along the guide groove 6 relative to the packaging bag 1, so as to ensure that the exhaust roller 3 always rolls the packaging bag 1, so that the gas in the packaging bag 1 can be automatically and completely exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com