A suction and exhaust system for molds used in ceramic tile pressing

A technology of pressing and forming and exhausting, which is applied in the field of exhausting and exhausting systems, can solve the problems of the decrease of the exhaust quality of ceramic powder and the influence of the quality of brick molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

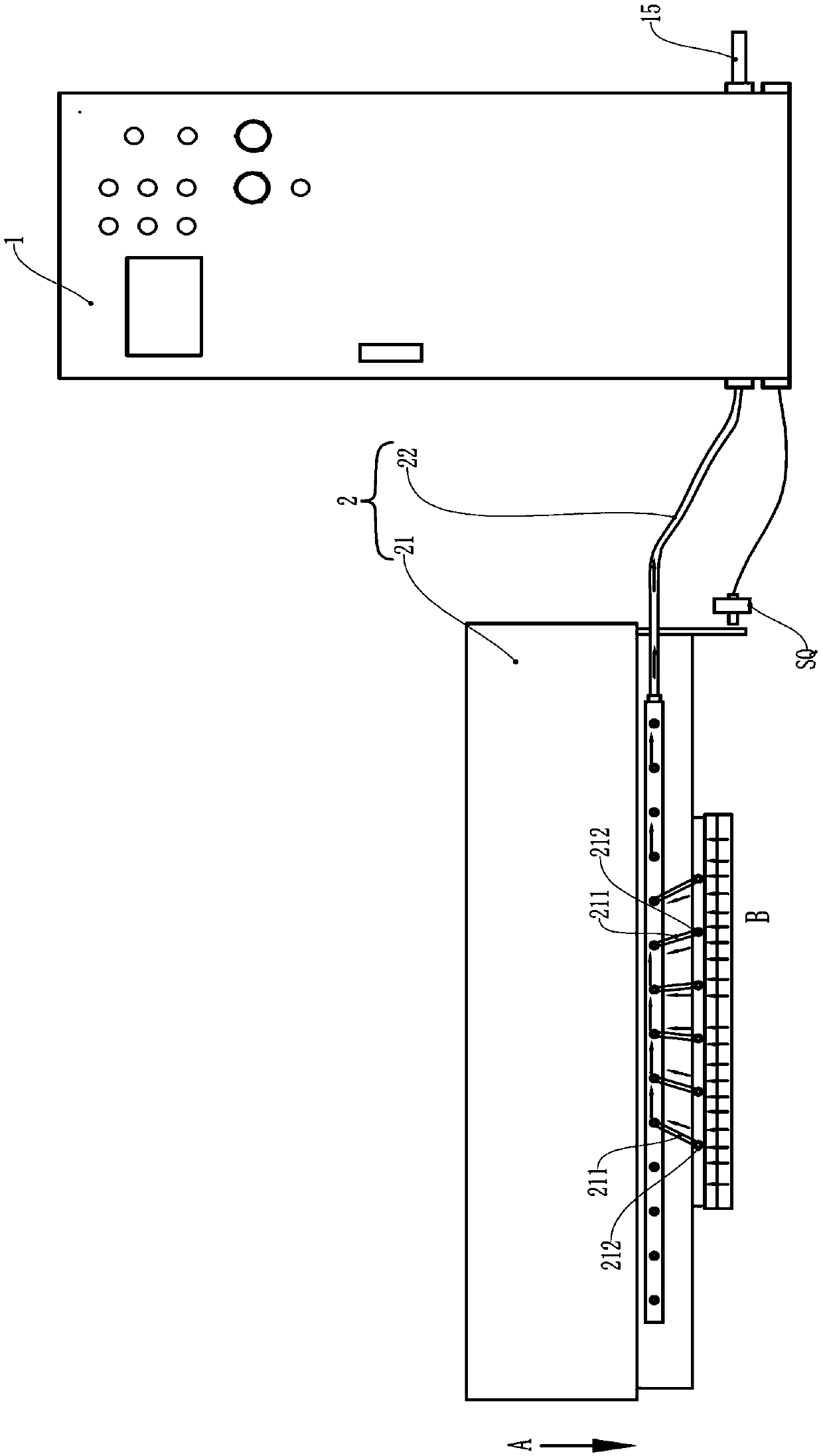

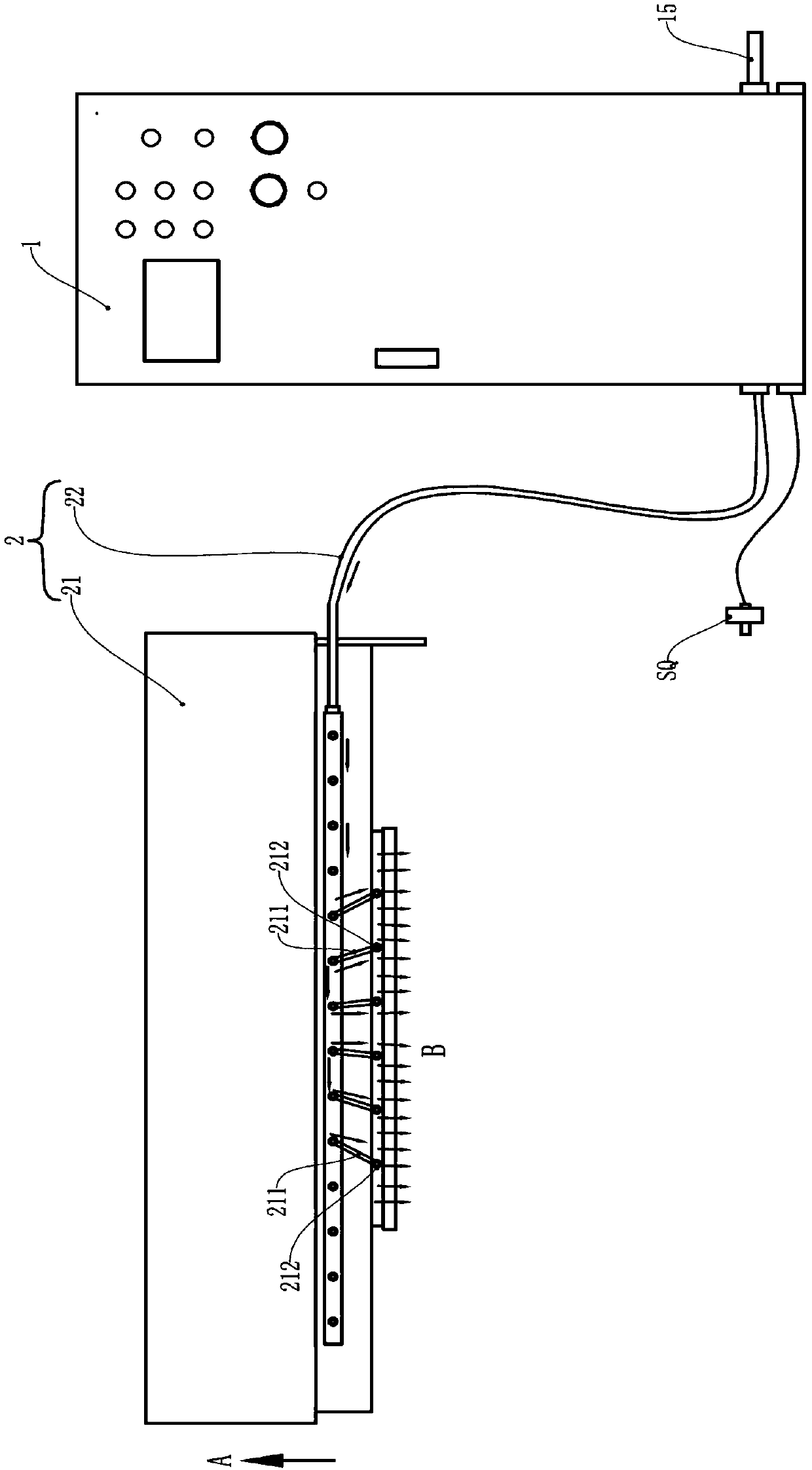

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

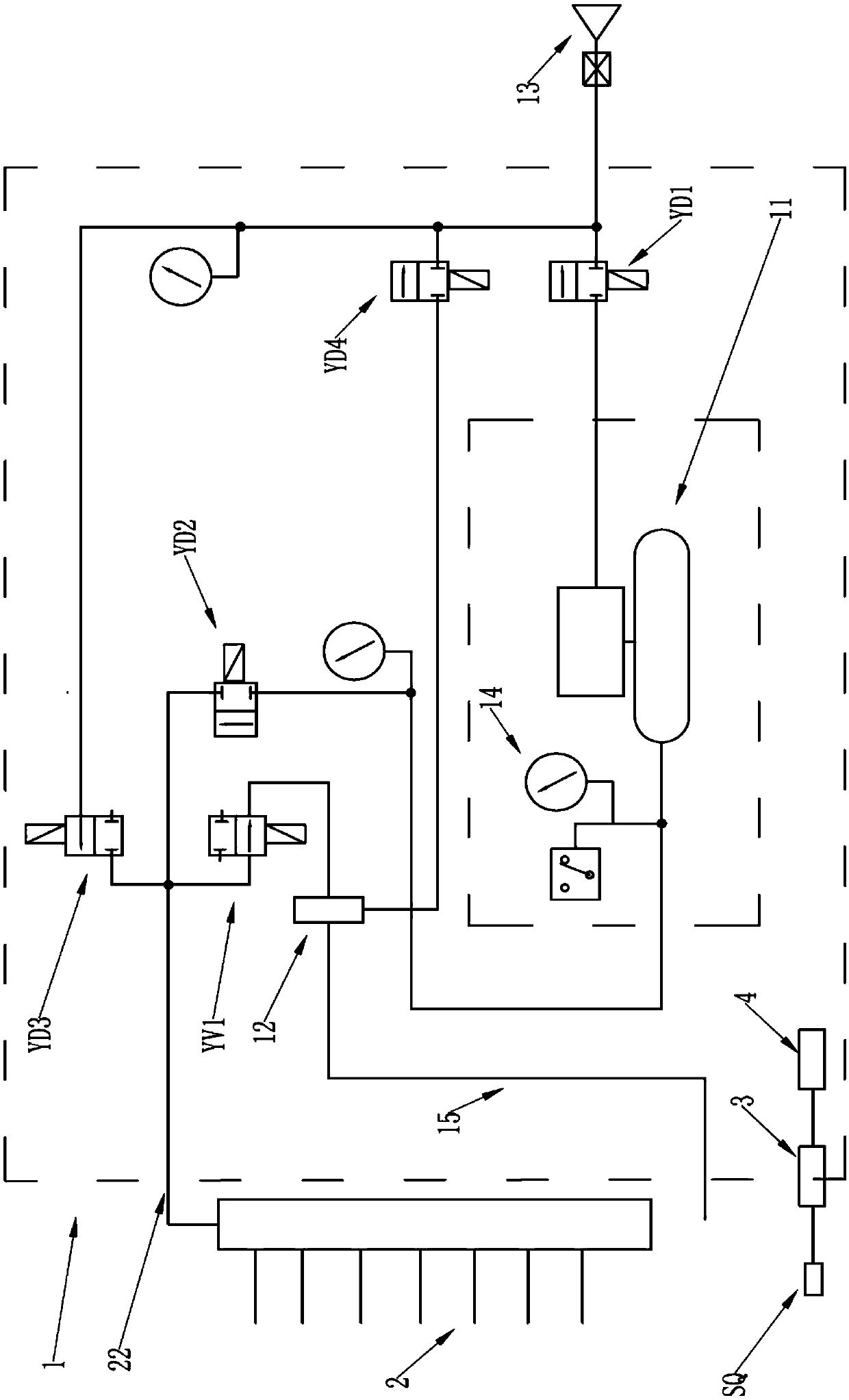

[0045] The exhaust system of the mould, which is used for ceramic tile press molding in this embodiment, is as Figures 1 to 3 As shown, it includes a gas monitoring system 1 and a tile mold core 2, and the gas monitoring system 1 is connected to the tile mold core 2;

[0046] Such as figure 1 As shown, the gas monitoring system 1 includes a booster pump 11, a solenoid valve A YD1, a solenoid valve YD2, a solenoid valve C YD3, a solenoid valve D YV1, a solenoid valve E YD4 and a fluidizer 12, and the solenoid valve A YD1 , Solenoid valve B YD2, Solenoid valve C YD3 and Solenoid valve E YD4 are all normally closed solenoid valves, and said solenoid valve D YV1 is a normally open solenoid gas valve; the input end of said booster pump 11 passes through Solenoid valve A YD1 The air source 13 is extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com