Tube pile out-of-pit conveying method

A transmission method and technology of pipe piles, which are applied in the directions of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of not solving the radial movement of pipe piles, unable to realize the radial movement of pipe piles, etc., achieving high precision and improving The effect of work efficiency and stable transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

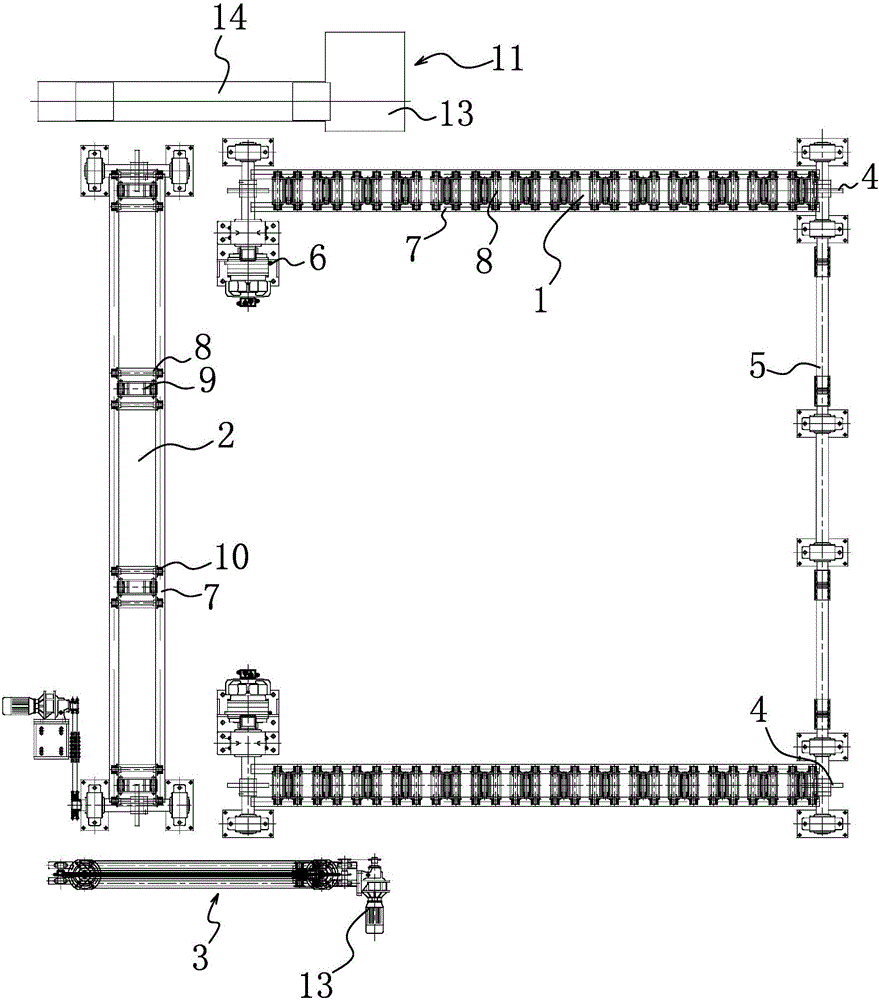

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

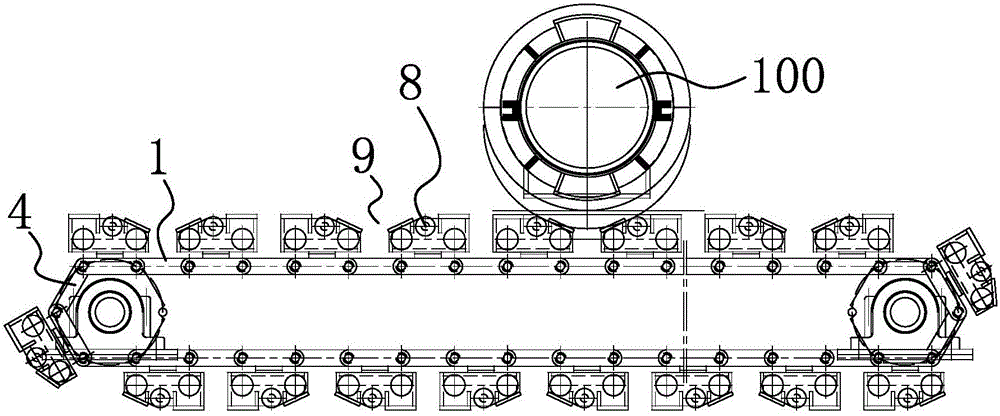

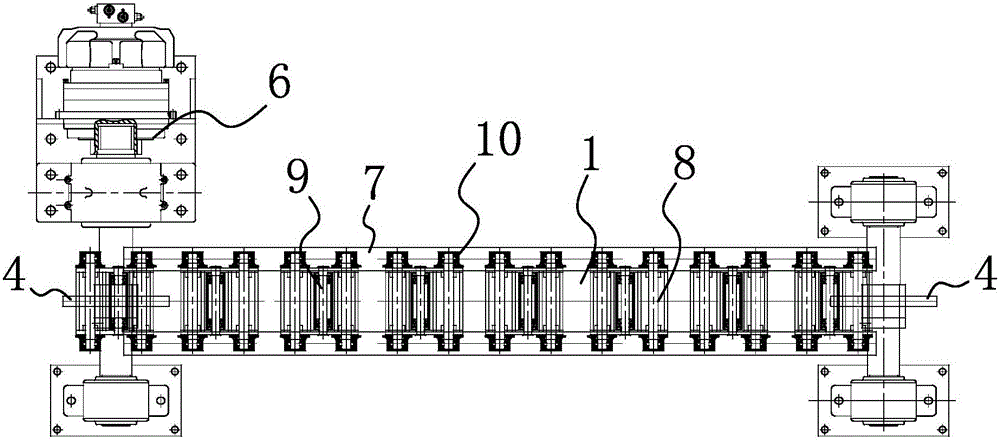

[0025] Such as figure 1 and figure 2 As shown, a method for transporting pipe piles out of pits includes placing pipe piles 100 on at least two radial transmission lines 1 parallel to each other, and the radial transmission lines 1 are moved synchronously so that the pipe piles move radially. It includes the step of placing the pipe pile on the axial transmission line 2 and using the axial transmission line 2 to move axially, and also includes the step of using the ferry mechanism 3 to move the pipe pile from the radial transmission line 1 to the axial transmission line 2 .

[0026] The radial transmission line 1 and the axial transmission line 2 can be a chain type transmission line, a rack type transmission line, or a crawler type transmission line, etc. Preferably, an annular transmission line structure should be formed. The pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com