Aluminum profile heating furnace

A heating furnace and aluminum profile technology, applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems of uneven heating and complex structure of profile heating furnace, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

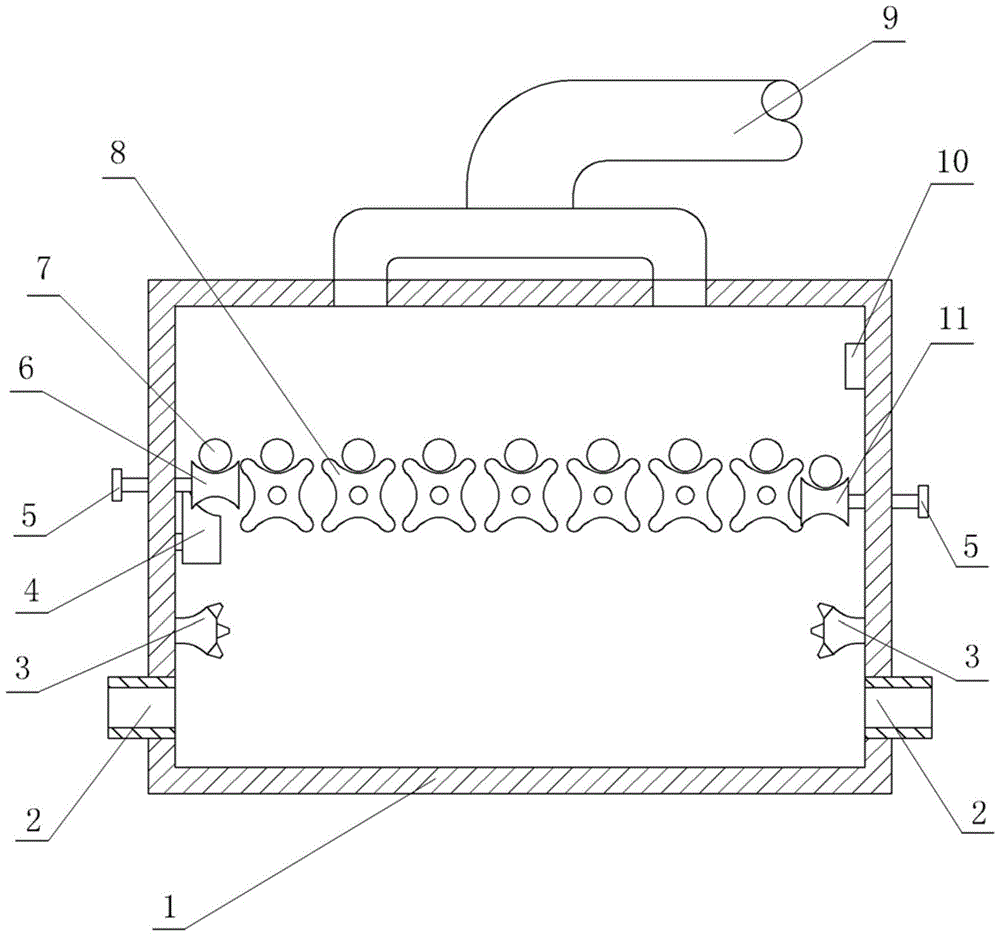

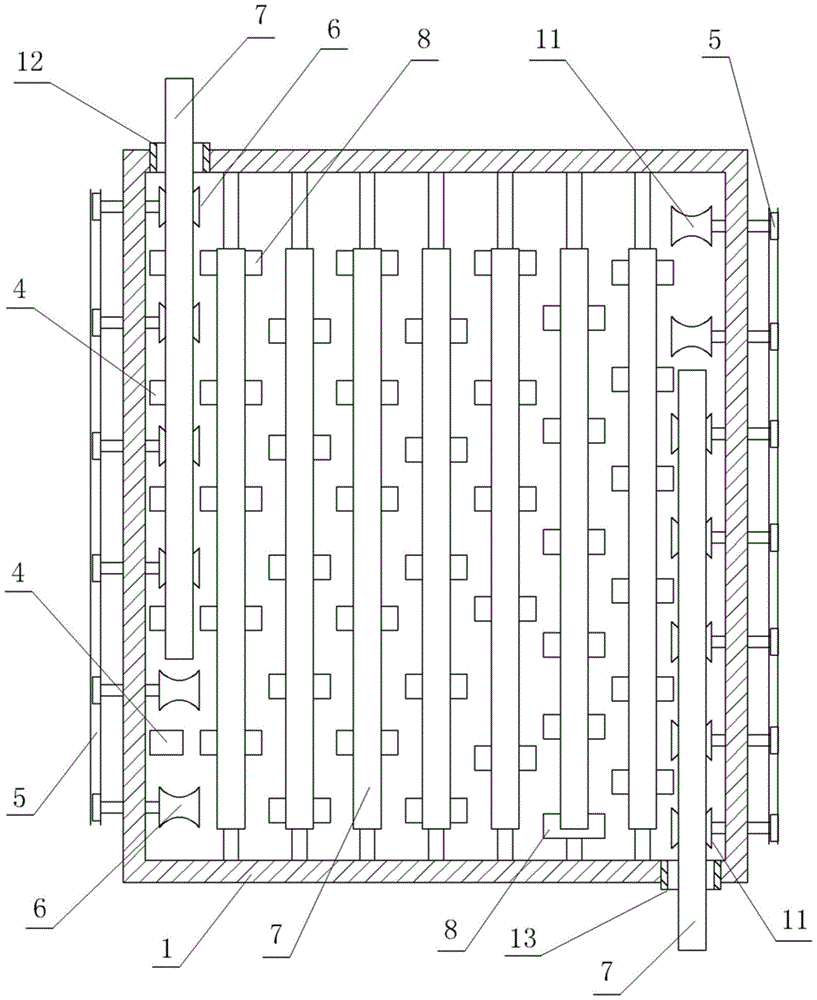

[0013] like figure 1 , figure 2 As shown, an aluminum profile heating furnace includes a furnace body 1, an air inlet 2 and an air outlet 9, the air inlet 2 is arranged at the bottom of the furnace body 1, and the air outlet 9 is arranged at the furnace body 1 top. Flame nozzle 3 and furnace temperature monitor 10 are arranged in described furnace body 1, and described flame nozzle 3 is a kind of burner, and fuel burns on described flame nozzle 3 and heats described furnace body 1 inside, so The furnace temperature monitor 10 is used to control the internal temperature of the body of furnace 1, and when the internal temperature of the body of furnace 1 reaches a set quality, the amount of fire sprayed by the burner nozzle 3 is automatically controlled, so that the body of furnace 1 The internal temperature is maintained within the set range. A feed inlet 12 and a discharge outlet 13 are arranged on both sides of the furnace body 1, and a feed roller 6 is arranged correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com