Piling Construction Technology and Equipment for Offshore Mobile Platform

A construction technology and mobile platform technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as unguaranteed piling accuracy, unguaranteed construction progress, and violent movement of piling ships, so as to improve operation efficiency and operation accuracy. , High piling accuracy, ensure the effect of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

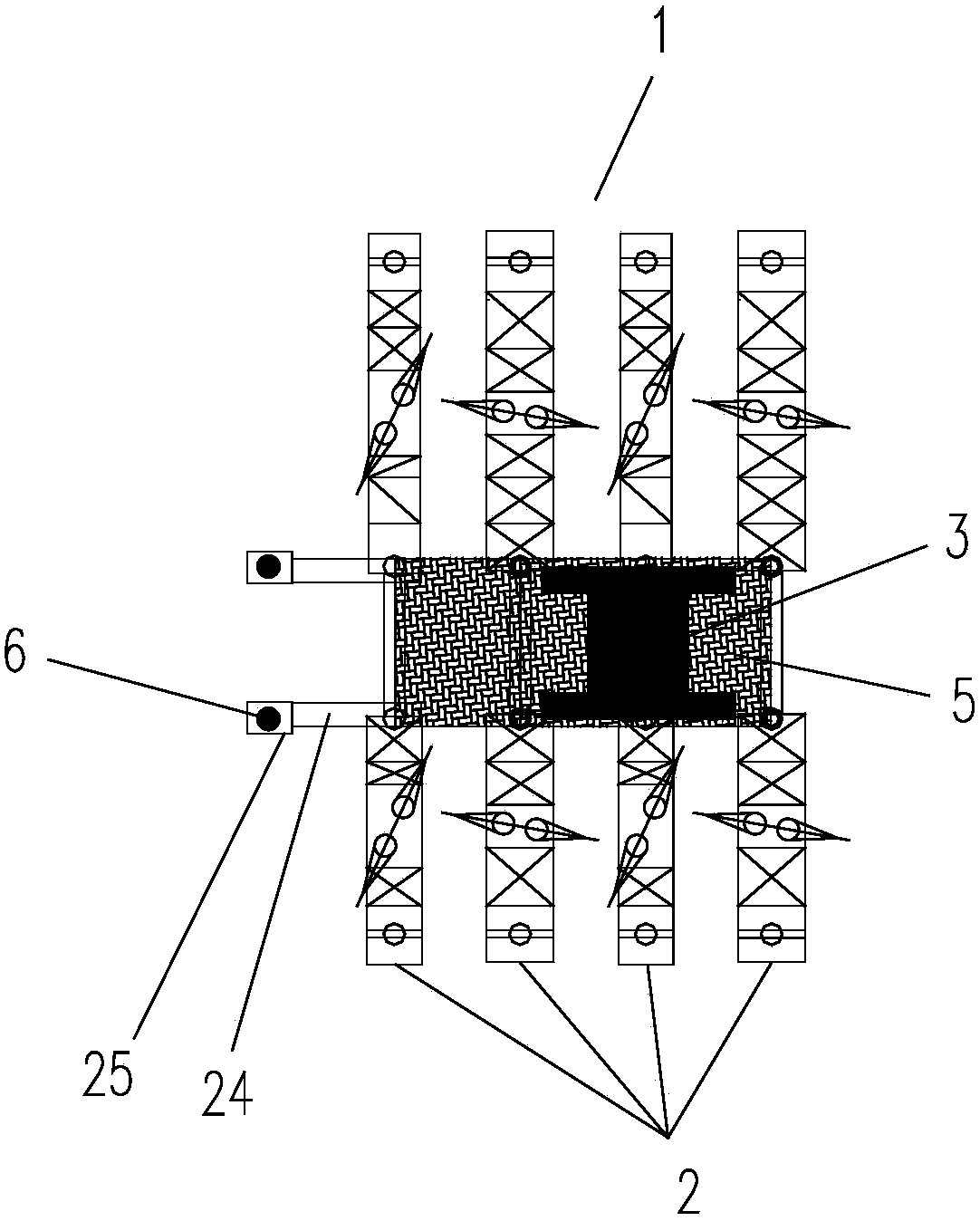

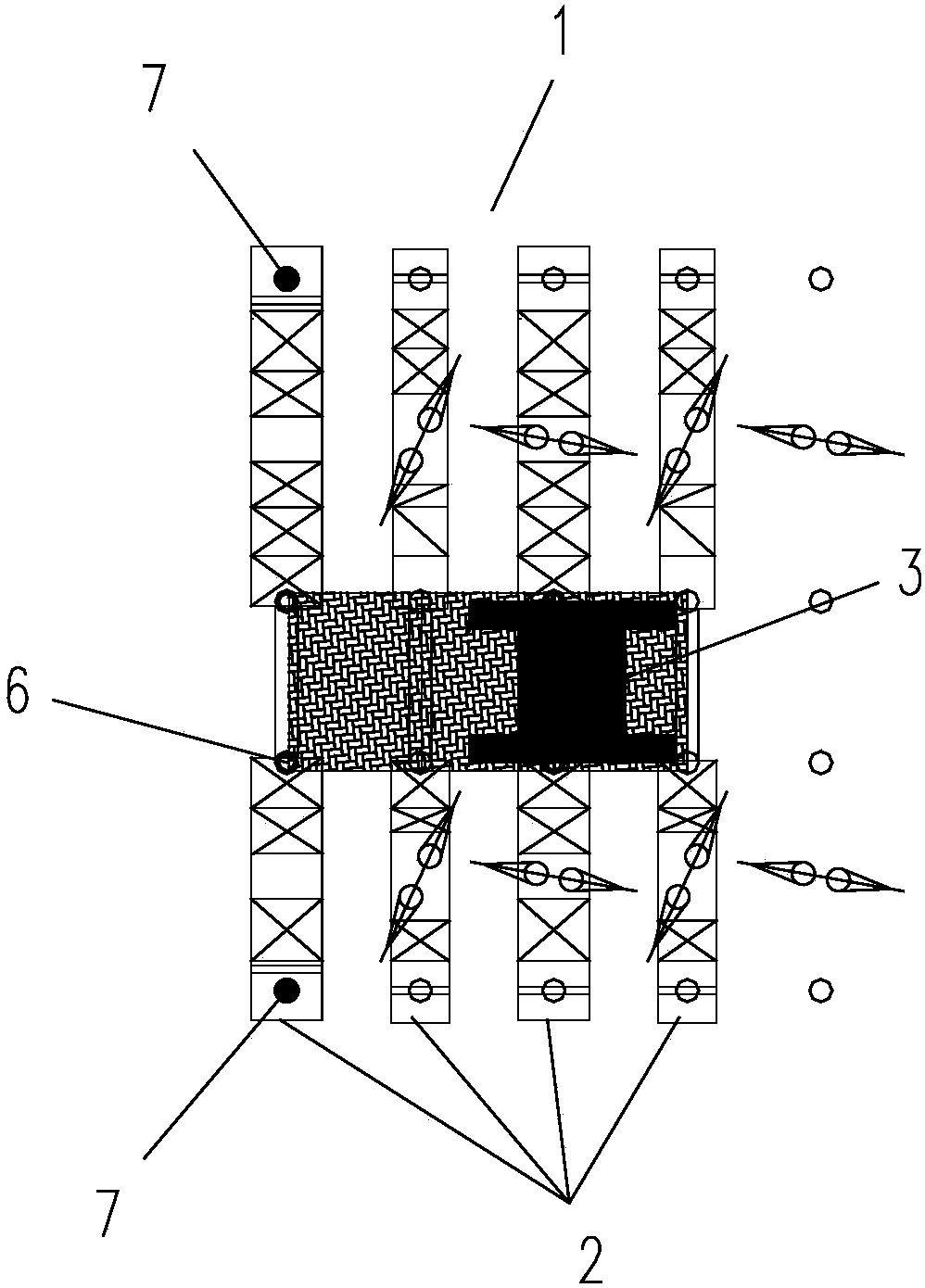

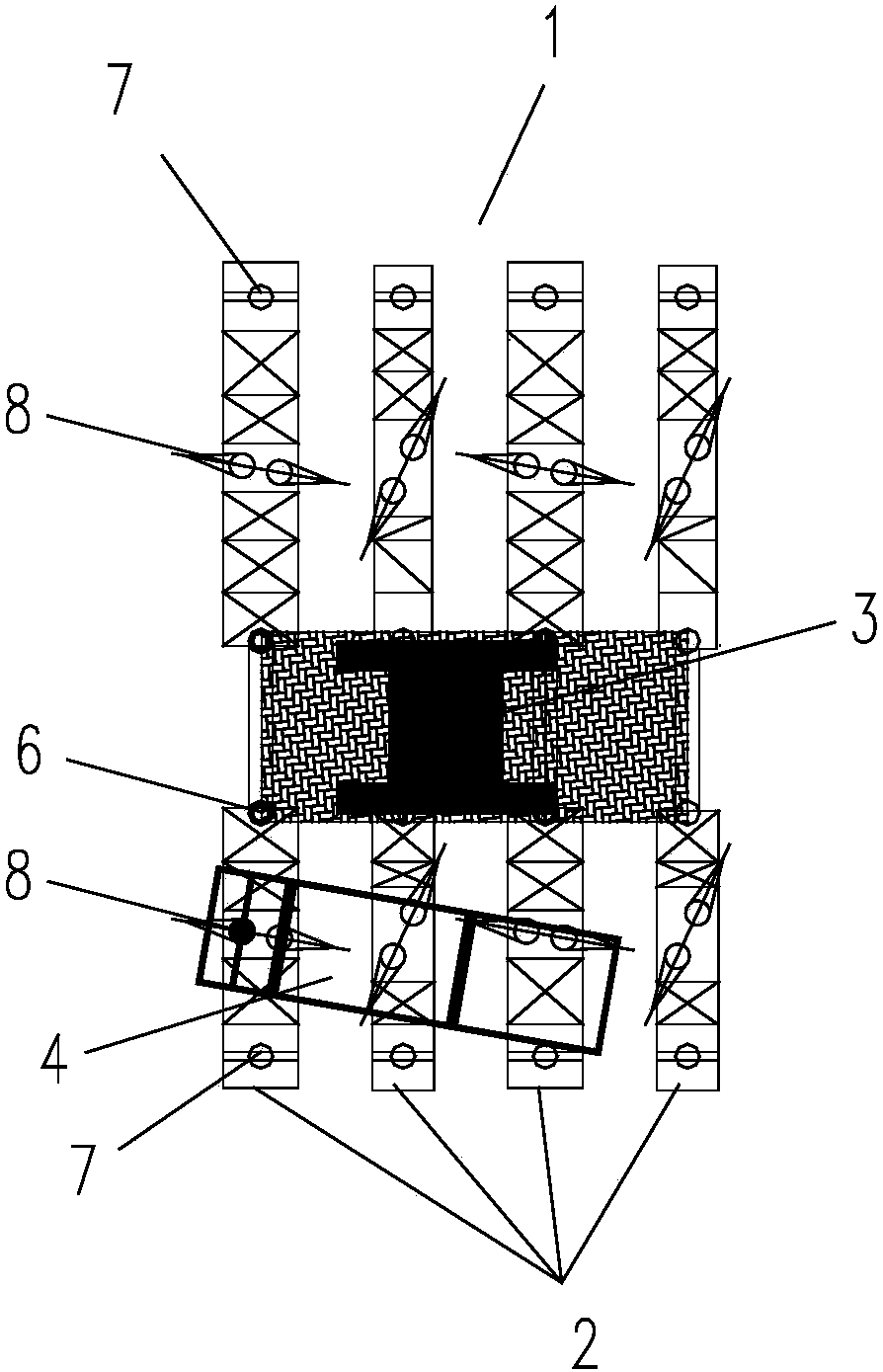

[0025] Such as Figures 1 to 4 as shown,

[0026] The piling construction process of the offshore mobile platform includes the following steps:

[0027] Set up the piling platform; first lay the piling platform on the land or shallow water area on the shore, because the influence of the surge or sea waves on the land and shoal is small, the piling platform can be accurately laid.

[0028] A straight pile beam is set on one side of the piling platform, and the next row of middle straight piles is driven through the straight pile beam, and the general beam is installed on the middle straight pile to form a piling platform, and the piling platform is moved circularly in the direction of piling.

[0029] After installing the general girder with the intermediate straight piles, use the cantilever positioning beams on both sides of the general girder to drive the supporting straight piles on both sides. At the top of the pile, the positioning beam in the cantilever state is change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com