Elbow connecting piece

A technology for elbow connections and connectors, applied in the field of pipeline connectors, which can solve the problems of inconvenient installation, poor sealing, and difficult maintenance of pipeline connectors, and achieve better results, prolong life, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0016] This example figure 1 as shown,

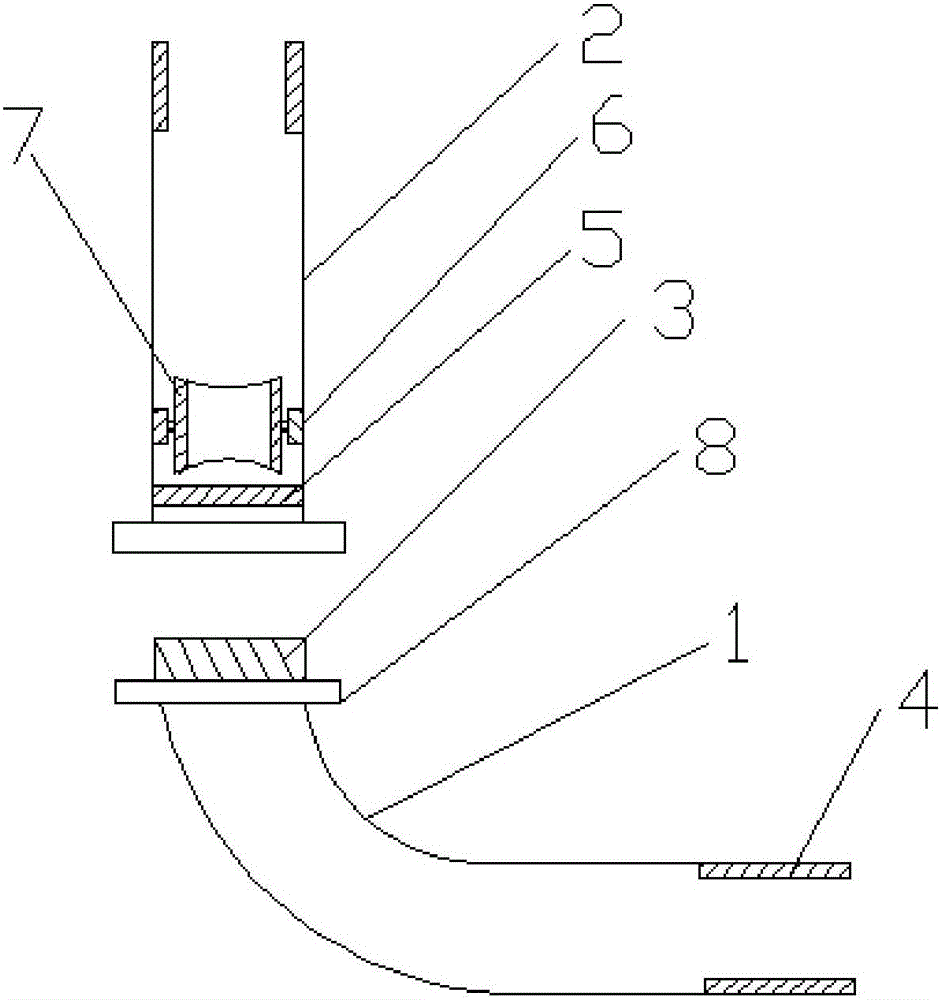

[0017] An elbow connector, which includes connector one 1 and connector two 2, said connector one 1 is provided with a mounting plate 8, said mounting plate 8 is provided with a joint 3, said connector one An anti-oxidation layer 4 is provided at the nozzle of the tail end of 1, and an annular protruding ring 5 made of molten material is provided inside the connector two (2), and a boss 6 is provided above the protruding ring 5 , the boss 6 is connected with a lining 7, the mounting plate 8 is an annular flange, the anti-oxidation layer 4 is made of aluminum material, and the lining 7 is a cylinder Shaped structure, the surface of the connector 2 is provided with an information marking unit, and the information marking unit is marked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com