A Method of On-line Measuring Fatigue Crack Propagation of Plexiglass

A fatigue crack propagation, plexiglass technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc., can solve the problems of inaccurate measurement results, complicated measurement procedures, inconvenient data processing, etc. Reliable results, simple data processing, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

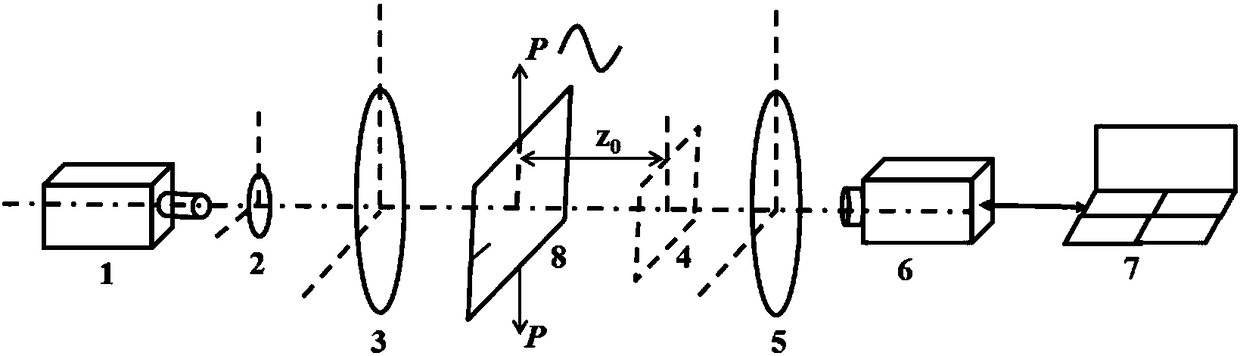

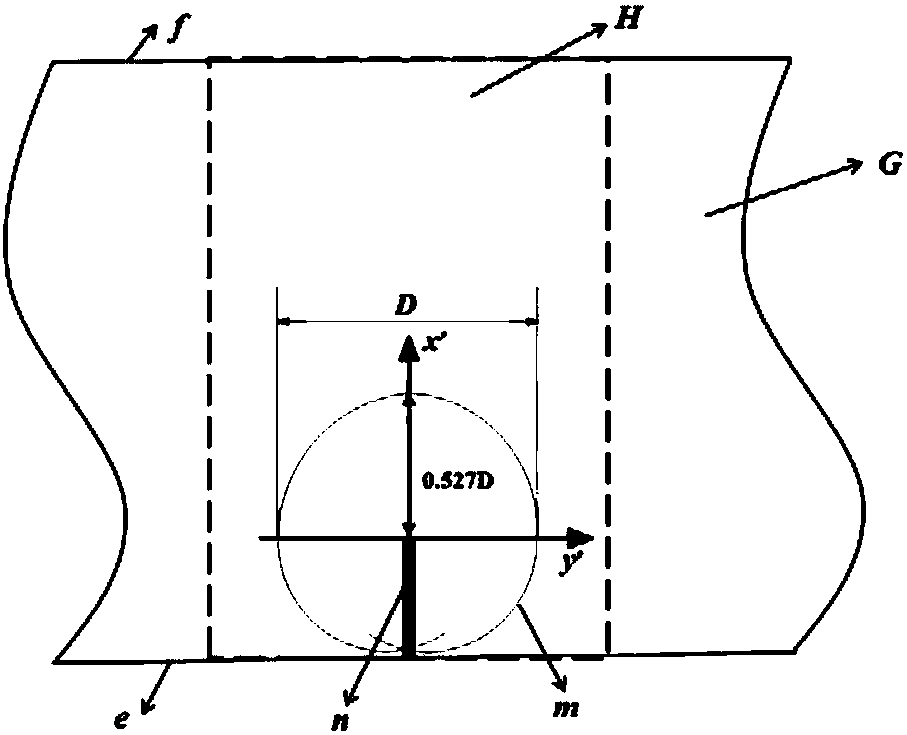

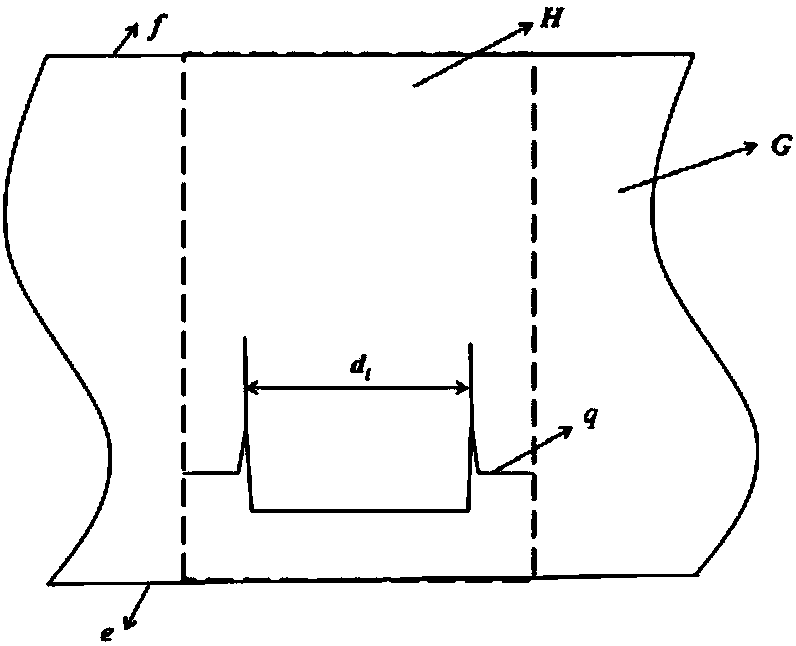

[0027] The method of the present invention utilizes a transmission type caustics optical testing system to obtain the caustic speckle image near the crack tip and the crack propagation process of the plexiglass fatigue crack propagation process, and through real-time image processing of the caustic speckle image in the computer buffer area, Online accurate calculation of crack length and crack tip stress intensity factor. Based on the real-time processing of a large amount of test data, conditions are selected for the caustic speckle images in the computer cache area, the number of focal speckle images stored in the near-threshold region expansion stage and the stable expansion stage is controlled, and the storage capacity of the fast tending to fracture toughness stage is improved. The number of focal spot images is increased, thereby improving the measurement accuracy of the plexiglass fatigue crack growth test, while reducing the amount of image storage and data analysis and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com