Temperature control circuit and temperature control method for hot knife mechanism

A technology of temperature control circuit and hot knife, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of increasing production cost, little relationship between resistance and temperature change, increasing the power of hot rod, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

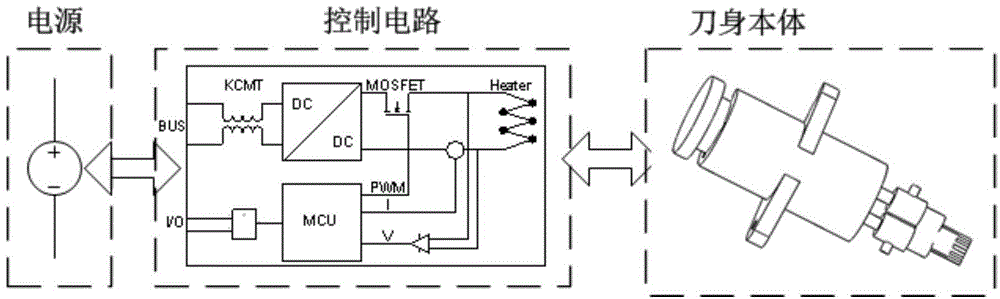

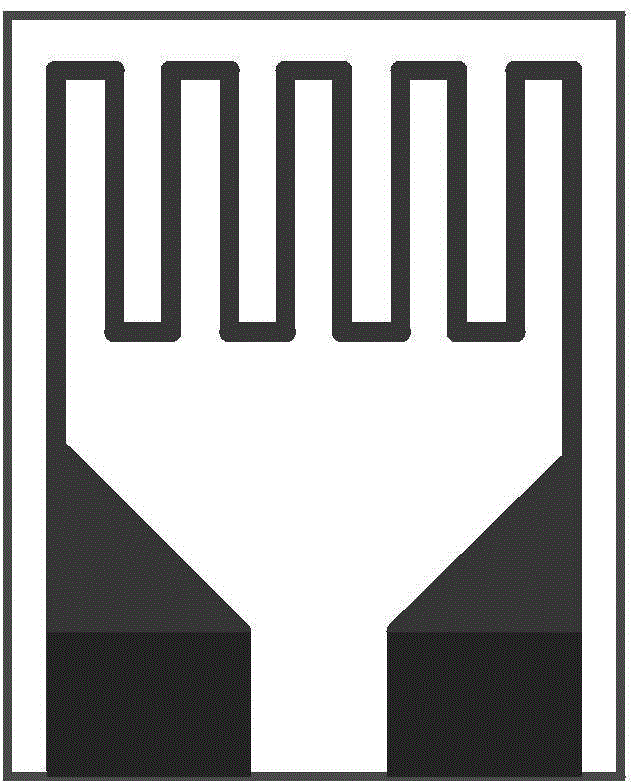

[0023] Such as figure 1 As shown, the whole system is composed of power supply, control circuit and blade body. Such as Figure 4 As shown, the blade body is mainly composed of an end cover 1, a spring 2, a blade body 3, a slider 4, a connecting rod 5, a set screw 6, an electrode 7 and an electric heating element 8. Wherein, end cover 1 is connected with the left end of spring 2; The right end of spring 2 is connected with the left end of slide block 4; Slide block 4 is positioned at the cavity of knife body 3; The connection with the left end of the electrode 7 adopts a direct plug-in type, and then is fixed with a set screw and connected with the relative thread. The right end of the electrode 7 is connected with the heating element 8 .

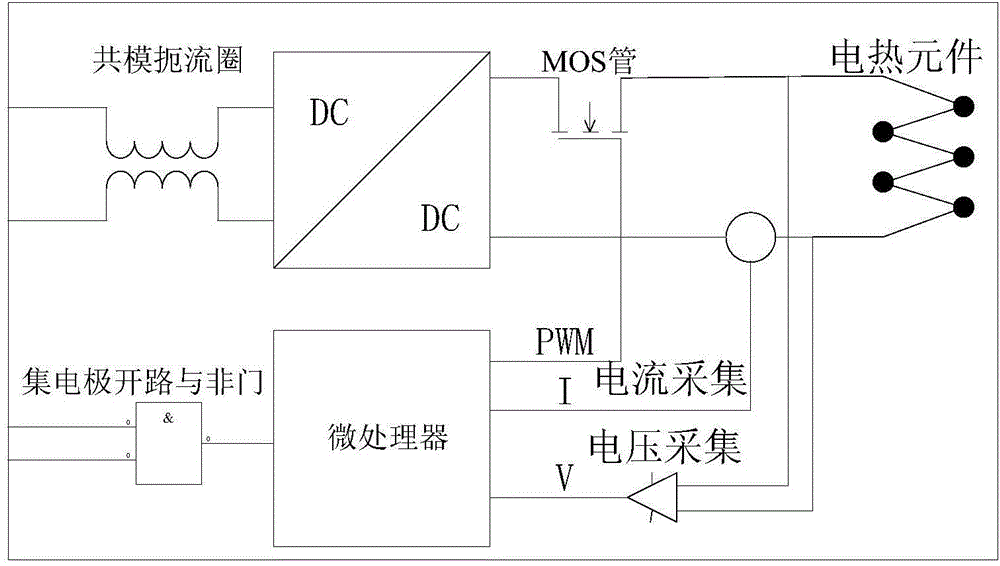

[0024] The temperature control circuit of the hot knife is as figure 2 shown. The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com