A temperature control circuit and method for hot knife mechanism

A technology of temperature control circuit and hot knife, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of calculating the blade temperature from the resistance value of the hot wire blade, not monitoring the temperature, and increasing the power of the hot rod And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

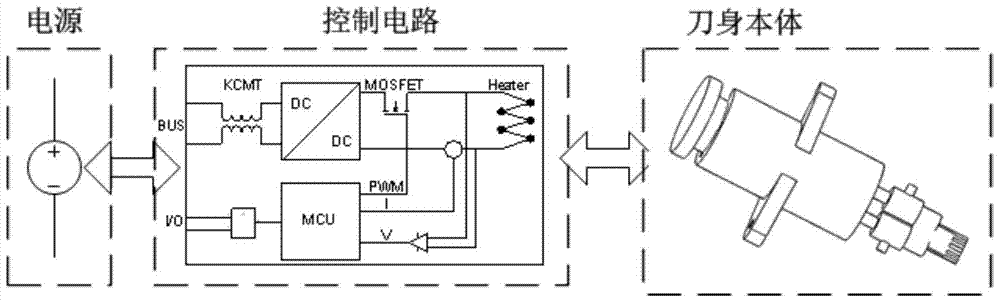

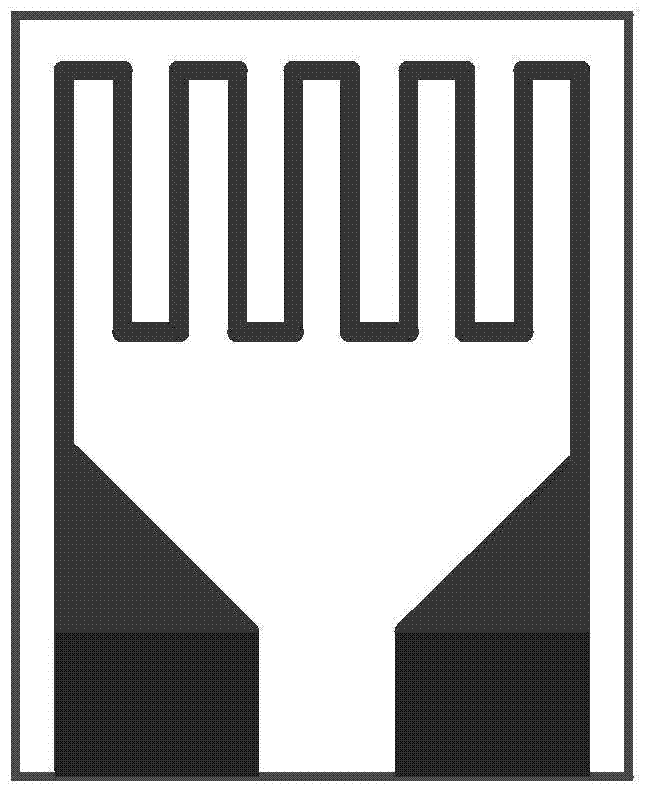

[0023] like figure 1 As shown, the whole system is composed of power supply, control circuit and blade body. like Figure 4 As shown, the blade body is mainly composed of an end cover 1, a spring 2, a blade body 3, a slider 4, a connecting rod 5, a set screw 6, an electrode 7 and an electric heating element 8. Wherein, end cover 1 is connected with the left end of spring 2; The right end of spring 2 is connected with the left end of slide block 4; Slide block 4 is positioned at the cavity of knife body 3; The connection with the left end of the electrode 7 adopts a direct plug-in type, and then is fixed with a set screw and connected with the relative thread. The right end of the electrode 7 is connected with the heating element 8 .

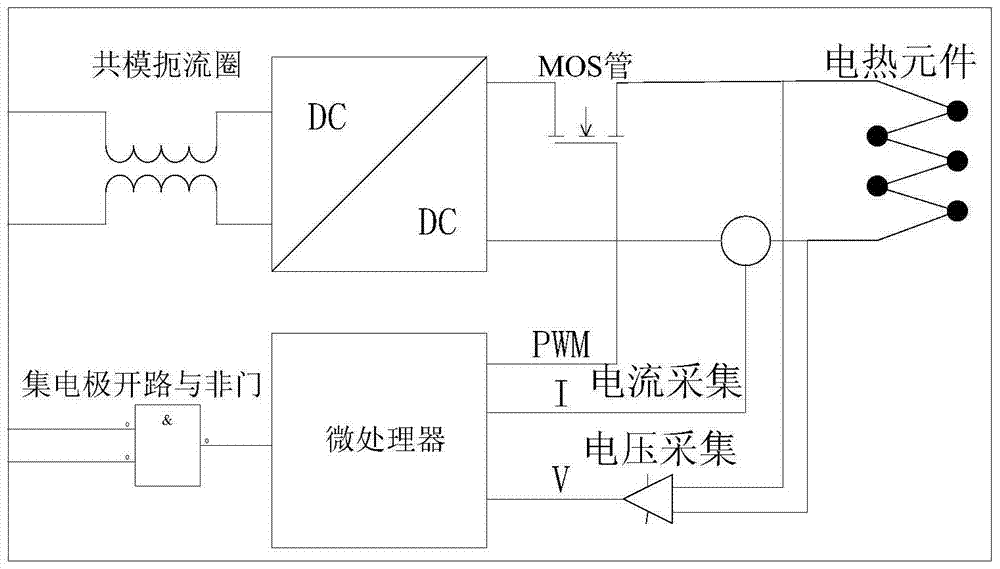

[0024] The temperature control circuit of the hot knife is as figure 2 shown. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com