Processing Method of Optical Spherical Surface Parameters Based on Discrete Error Elimination Technology

A technology of error elimination and parameter processing, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems affecting the performance of optical instrument systems, optical mirror surface deformation, etc., to achieve the effect of eliminating discrete errors and accurate engineering calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

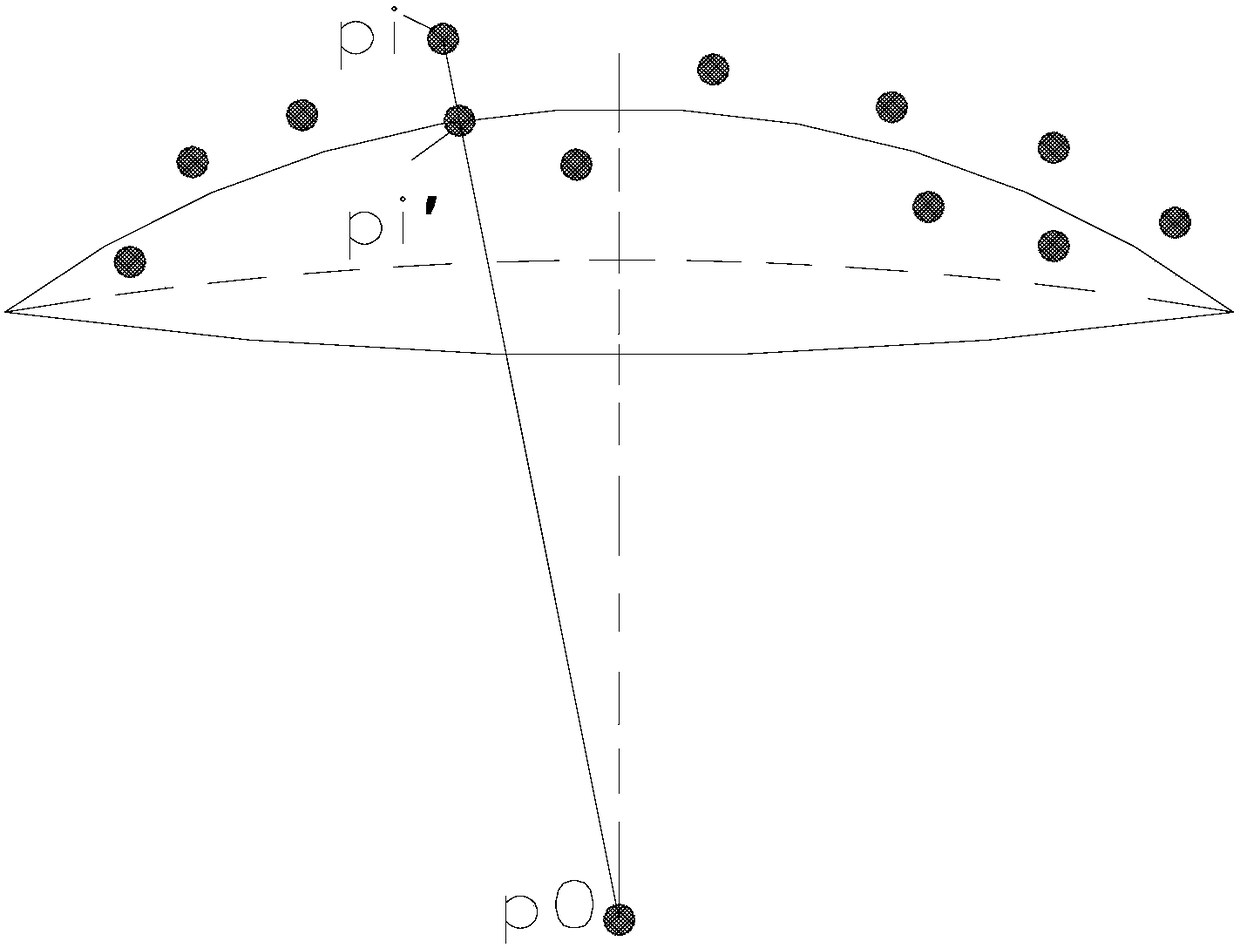

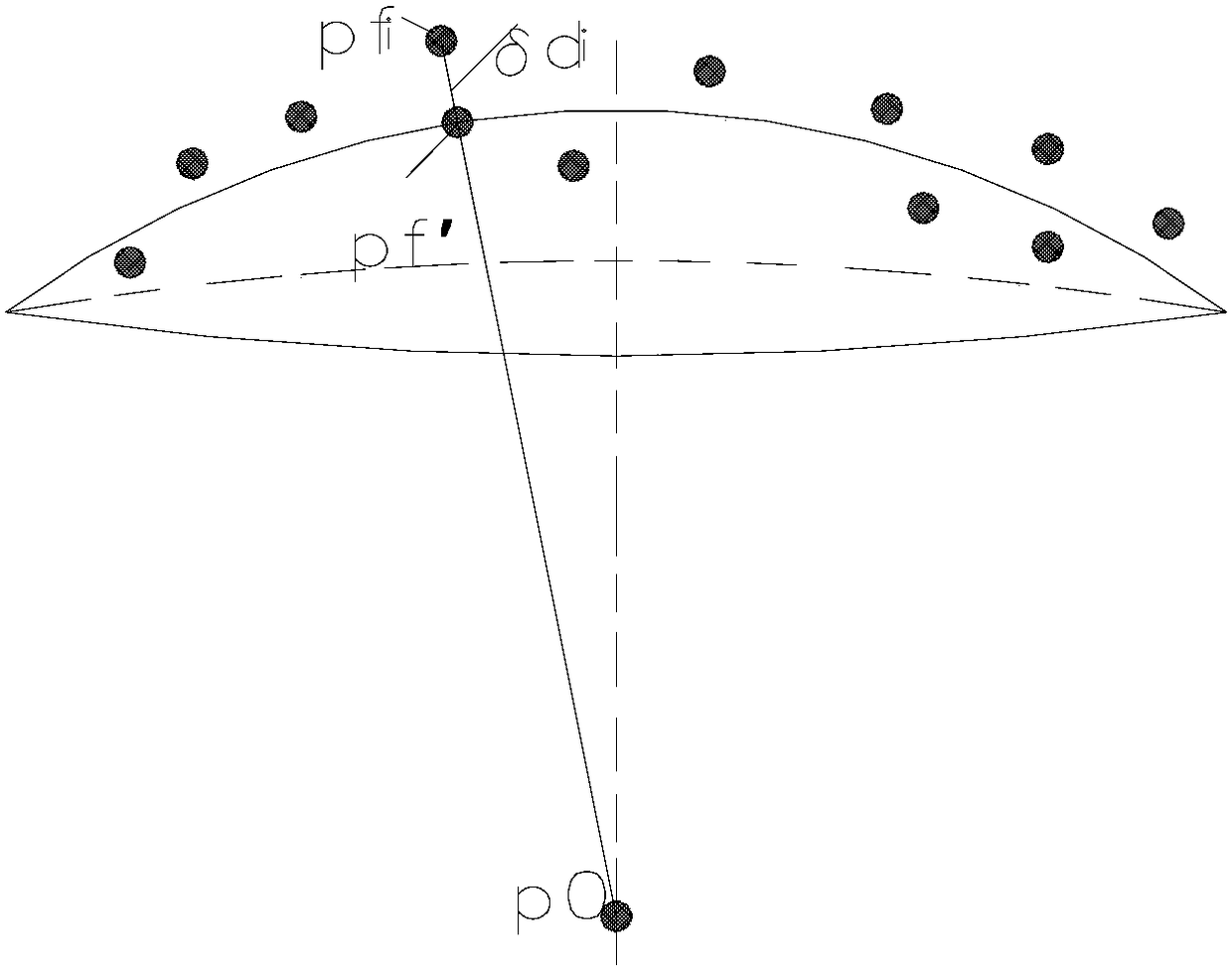

[0034] Due to the different optical surface shapes, the specific methods for solving the surface parameters are different. The method for solving the parameters of commonly used spherical optical mirrors is comprehensively given, that is, the method for solving the surface parameters of the spherical surface based on the finite element discrete error elimination algorithm, in order to improve the optical surface parameters. Shape parameter solution accuracy.

[0035] [1] Optical surface shape and finite element discretization

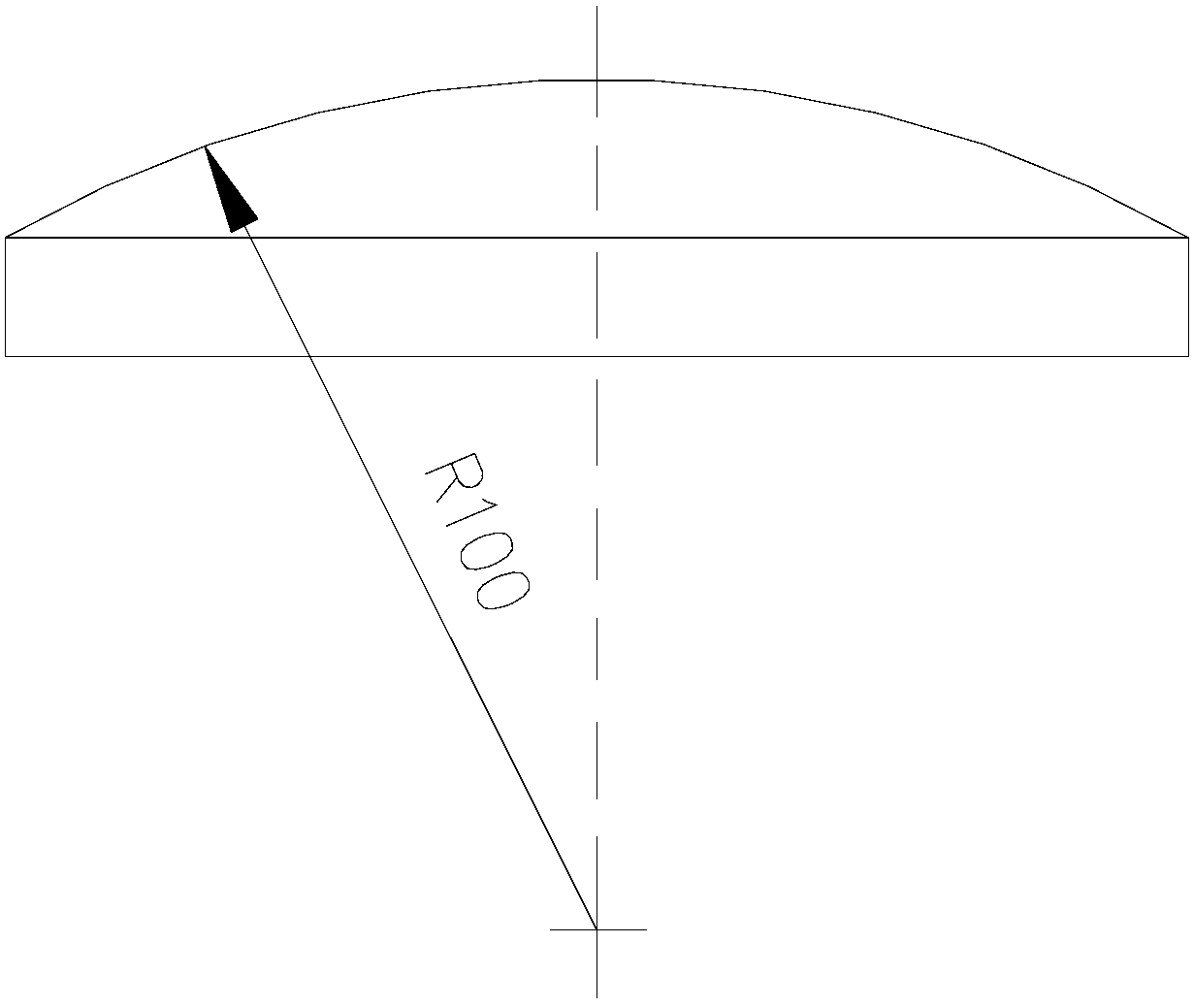

[0036] like image 3 , based on the CAD model of the spherical surface and finite element discretization; the theoretical surface shape parameters of the spherical surface (a, b, c, R) = (0,0,0,100) are known.

[0037] The grid model of the discrete back shape is as follows, the original coordinate data of the surface shape and the deformed surface shape change data are extracted in the finite element pre-processing program, and saved as a text file th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com