Lens distortion correcting method and system used for automatic optical detection

An automatic optical detection and lens distortion technology, applied in image data processing, instruments, calculations, etc., can solve the problems of low corner extraction accuracy, large result error, poor correction effect, etc., and achieve high corner extraction accuracy and good effect. , the effect of reasonable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

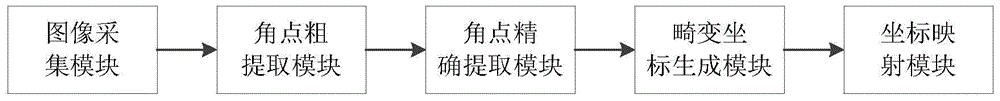

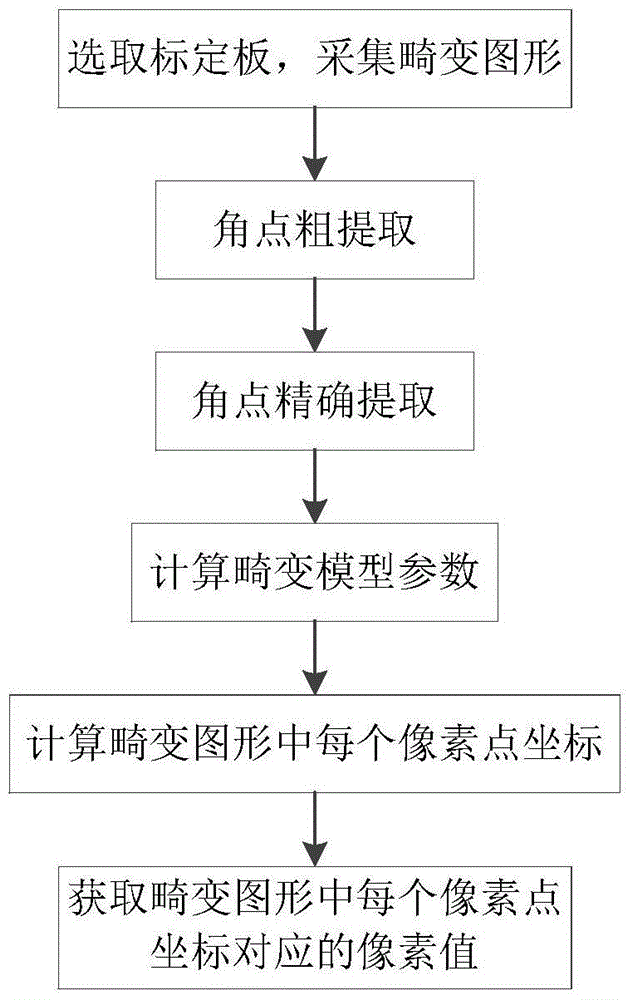

[0036] Such as figure 1 As shown, the present invention is a lens distortion correction system for automatic optical detection, including:

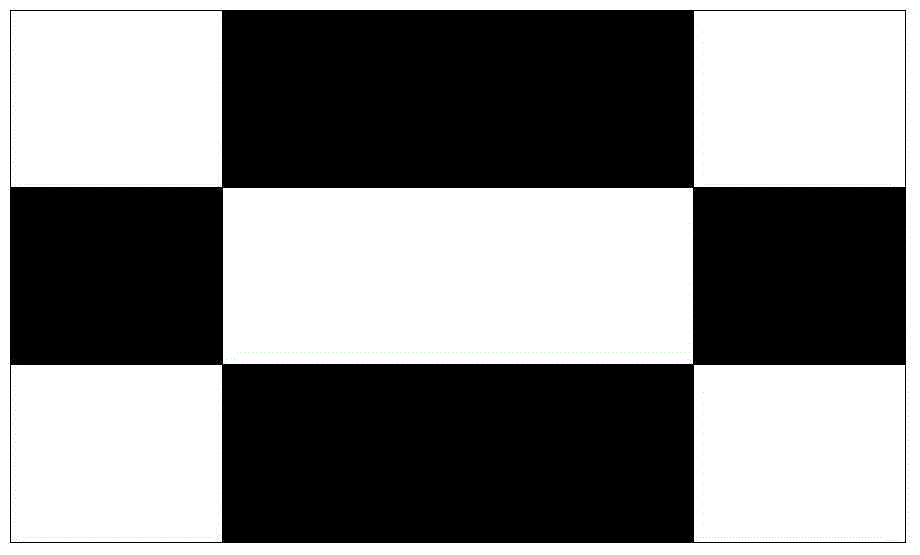

[0037] The image acquisition module is used to collect the distortion graphics and send the distortion graphics to the corner point rough extraction module; the image acquisition module includes a distortion graphics acquisition module, which is used for calibration of the lens to be corrected after selecting the non-uniform checkerboard as the calibration board The board obtains the distorted graphics;

[0038] The corner point rough extraction module is used to perform rough corner point extraction on the received distorted graphics to obtain dense corner points and send them to the corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com