Method for Hierarchical Management of Nuclear Power Plant Periodic Test Supervision Requirements

A periodic test and hierarchical management technology, applied in the field of regular test supervision safety management, can solve the problems of personnel safety impact, consumption of power plant management resources, large safety margin, etc., to strengthen management and control, strengthen safety management level, and improve safety The effect of management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

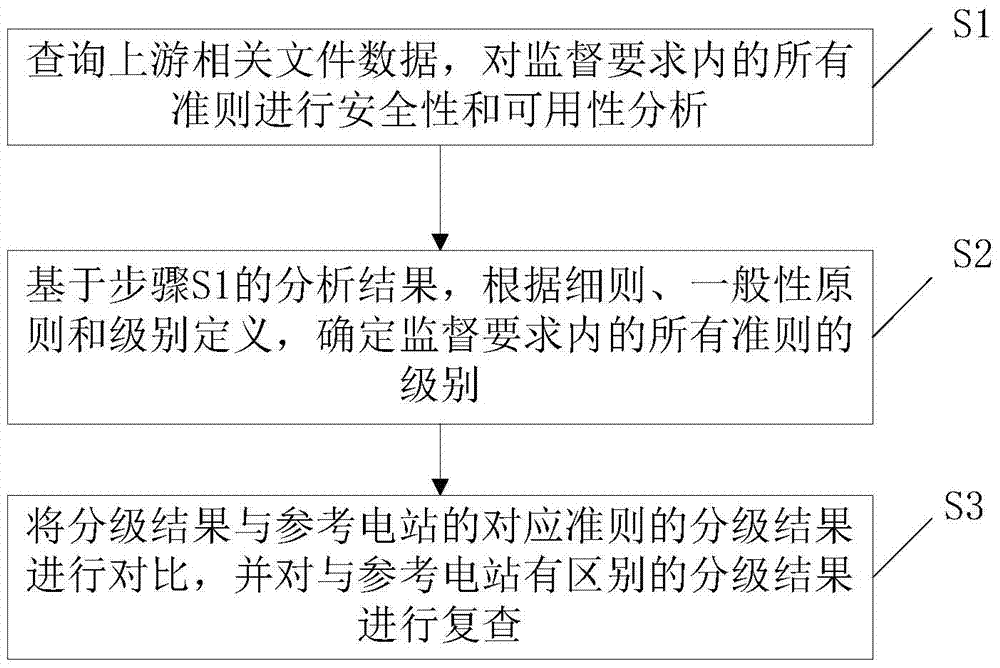

Method used

Image

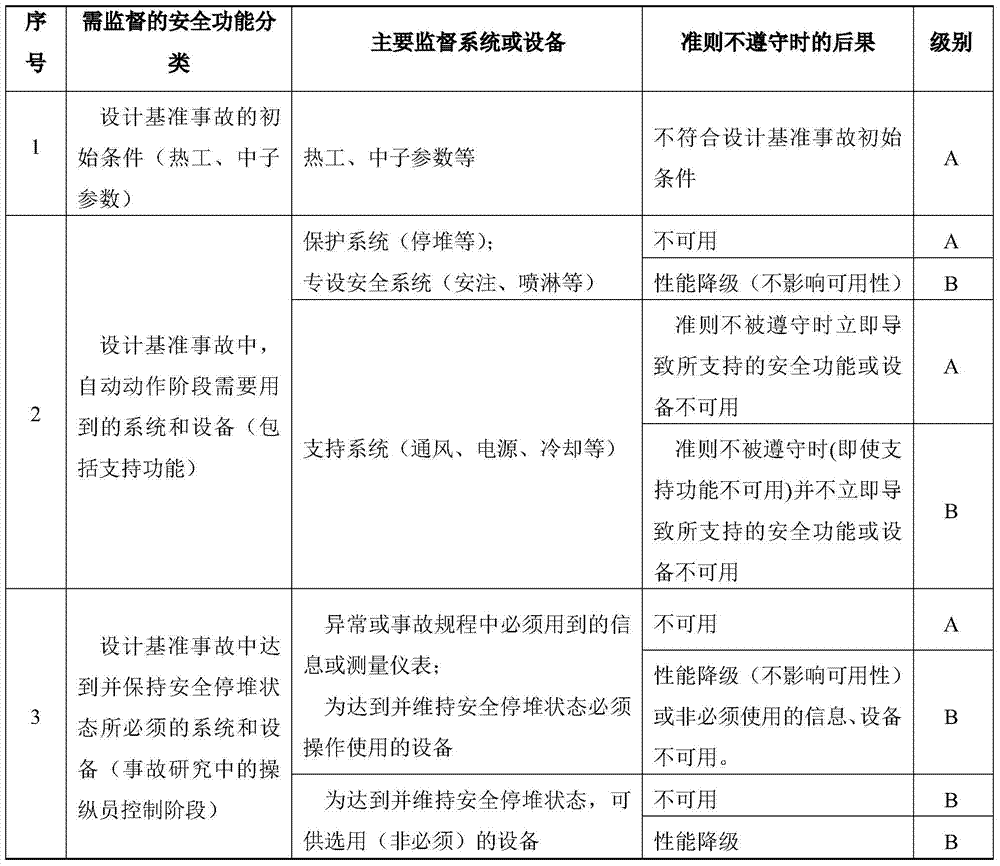

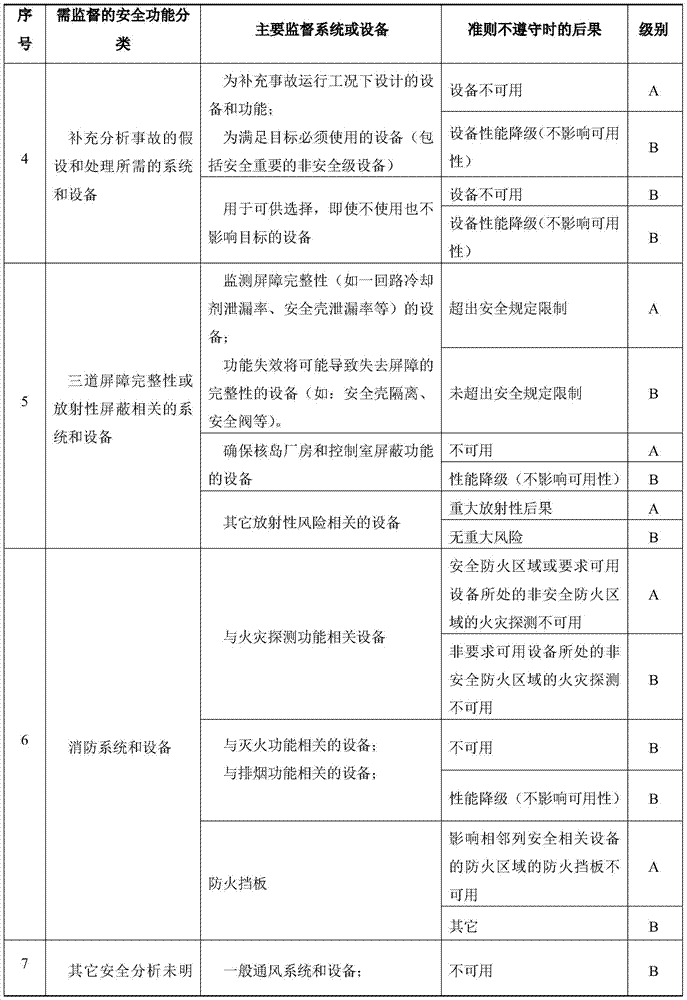

Examples

Embodiment 1

[0061] This embodiment is used to illustrate the classification by detailed rules, as shown in Table 3 below, it is to classify the criterion of the isolation valve "closing of 1TEP053VP-2TEP054VP". According to step S2, first use the detailed rules to judge, because it belongs to the isolation valve, so look up the detailed rules of the valve class in Table 2, since this embodiment is for the closure of 1TEP053VP-2TEP054VP, so the content of 7.8 in Table 2 can be used Based on the criterion for judging the "closing of 1TEP053VP-2TEP054VP", according to 7.8 in Table 2, it can be seen that the criterion of "closing of 1TEP053VP-2TEP054VP" belongs to level A.

[0062] table 3

[0063]

[0064]

[0065]

Embodiment 2

[0067] This embodiment is used to illustrate classification by general principles, as shown in Table 4 below, according to step S2, first use the detailed rules to judge, because it belongs to the sensor, so find the detailed rules of the sensor class, and according to the analysis of the upstream file in step S1 It can be seen that there is no relevant standard for its function in the detailed rules of the sensor class, so the detailed rules cannot classify the criteria in Table 4, so the general principle is adopted, and it can be determined from the analysis of the upstream file in step S1 that it should refer to the general The 7th in the principle, so the criterion of this embodiment belongs to the B level.

[0068] Table 4

[0069]

[0070]

[0071] In summary, implementing the method for hierarchical management of nuclear power plant periodical test supervision requirements of the present invention has the following beneficial effects: the present invention analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com