A method for encapsulating and preparing a highly stable silver nanowire composite film

A technology of silver nanowires and composite films, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of increasing the difficulty of processing technology, increasing the cost of large-scale process equipment, and transparent silver nanowires The effect of improving the adhesion between the conductive film and the substrate is limited, and the effect of increasing the anti-oxidation ability and anti-corrosion ability and reducing the cost of equipment is achieved, and the effect is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

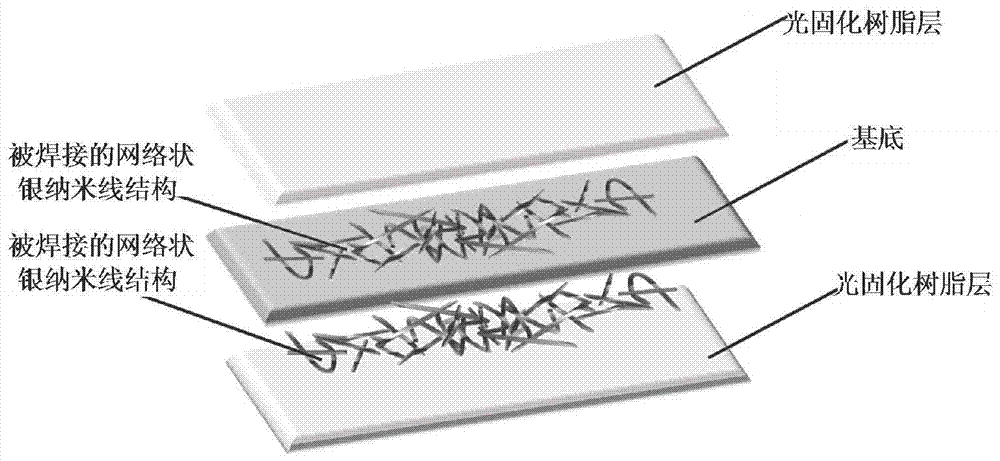

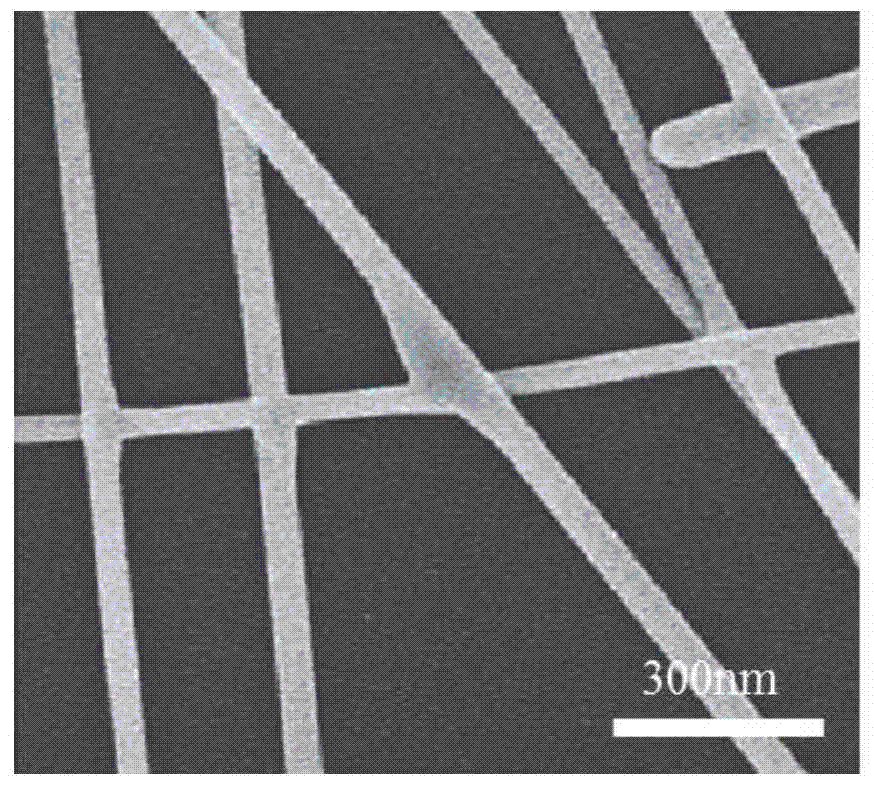

[0035] Embodiments and drawings will be given below to clearly illustrate the technical solution of the present invention.

[0036] The encapsulation preparation of the silver nanowire composite thin film of the present invention is carried out as follows:

[0037] a. Preparation of silver nanowire welding solution:

[0038] Using ethanol as a solvent, prepare a silver nitrate solution with a concentration of 10mmol / L and a glucose solution with a concentration of 10mmol / L;

[0039] After taking 10 mL of silver nitrate solution and 10 mL of glucose solution and shaking them well, add 1 mL of concentrated nitric acid with a mass fraction of 65% and 0.09 g of sodium hydroxide powder with a mass fraction of 96% and shake them up again, and the pH value is measured to be 1.7. Obtain silver nanowire soldering liquid;

[0040] b. Dispersed silver nanowires

[0041] Take 50mL of polyvinylpyrrolidone ethylene glycol solution with a concentration of 20mmol / L and 30mL of silver nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com