COB welding method and manufacturing method

A manufacturing method and wire bonding technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of prolonging COB manufacturing time and welding wire confusion, so as to reduce the frequency of replacing the welding wire process and reduce confusion probability, the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

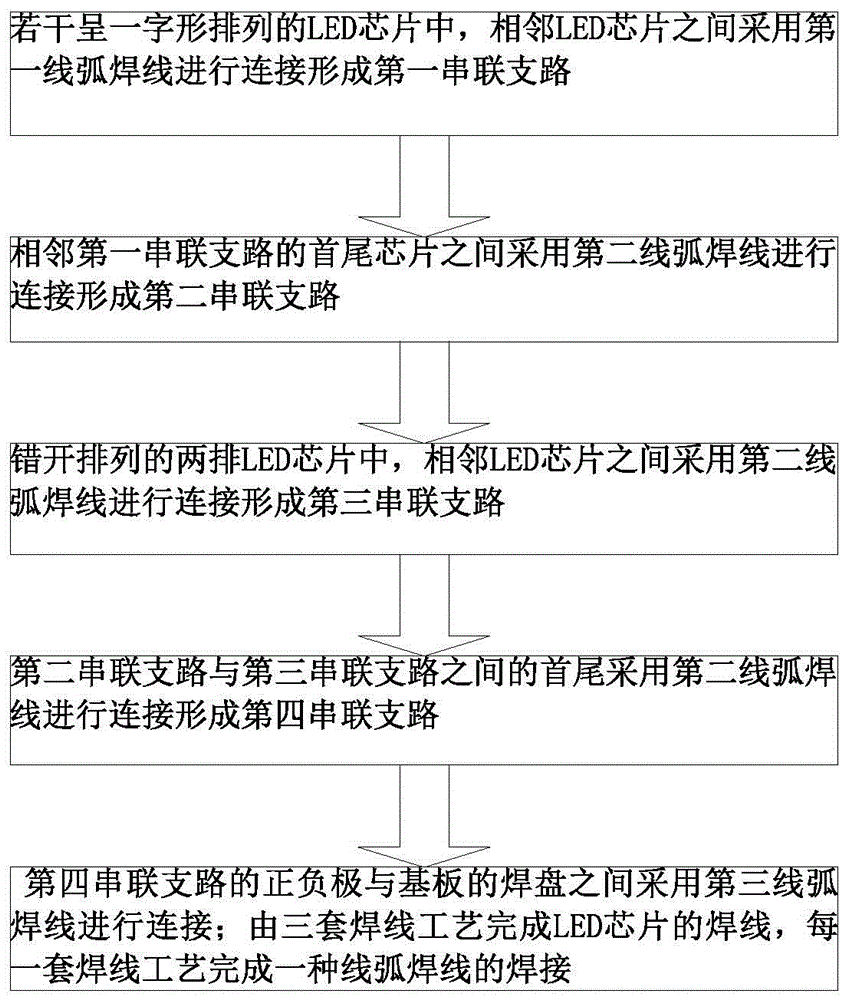

[0031] A COB manufacturing method, comprising a solid crystal step and a wire bonding step, comprising the following steps:

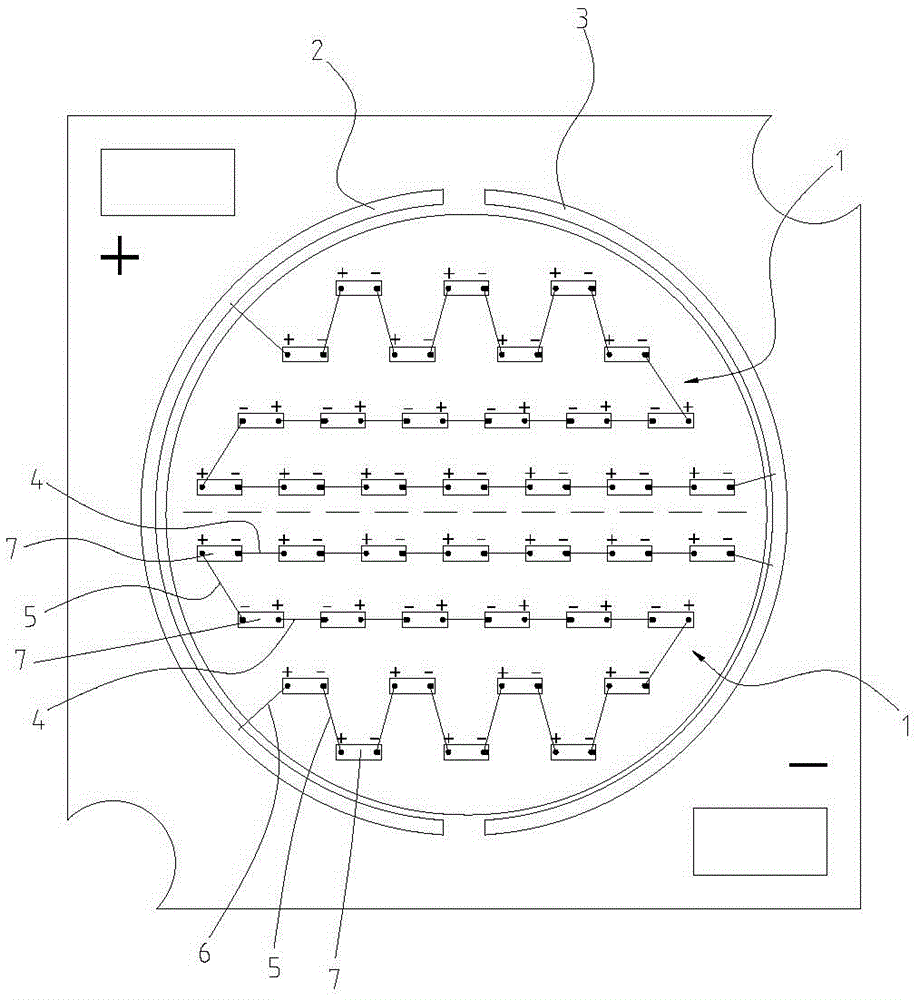

[0032] (1) solid crystal; such as figure 1 As shown, a circular crystal-bonding area is provided in the middle of the substrate, and positive electrode pads 2 and negative electrode pads 3 are respectively provided on both sides of the crystal-bonding area; the positive electrode pads and negative electrode pads are arc-shaped, And it is arranged along the edge of the crystal-bonding area; several LED chips 7 are respectively fixed in the two symmetrical half regions of the crystal-bonding area to form two light-emitting units 1, and the LED chips 7 of the two light-emitting units 1 are arranged symmetrically; the light-emitting In unit 1, the LED chips 7 arranged in a line are close to the middle of the die-bonding area, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com