Inner closed type radial flux magnetic transmission mechanism for underwater direct-driven propeller

A technology of radial magnetic flux and magnetic transmission, applied in the direction of permanent magnet clutches/brakes, electromechanical devices, electric components, etc., can solve the problems of regular inspection and maintenance, complex sealing structure and leakage, etc., to avoid overload damage, The effect of simple magnetic steel arrangement and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

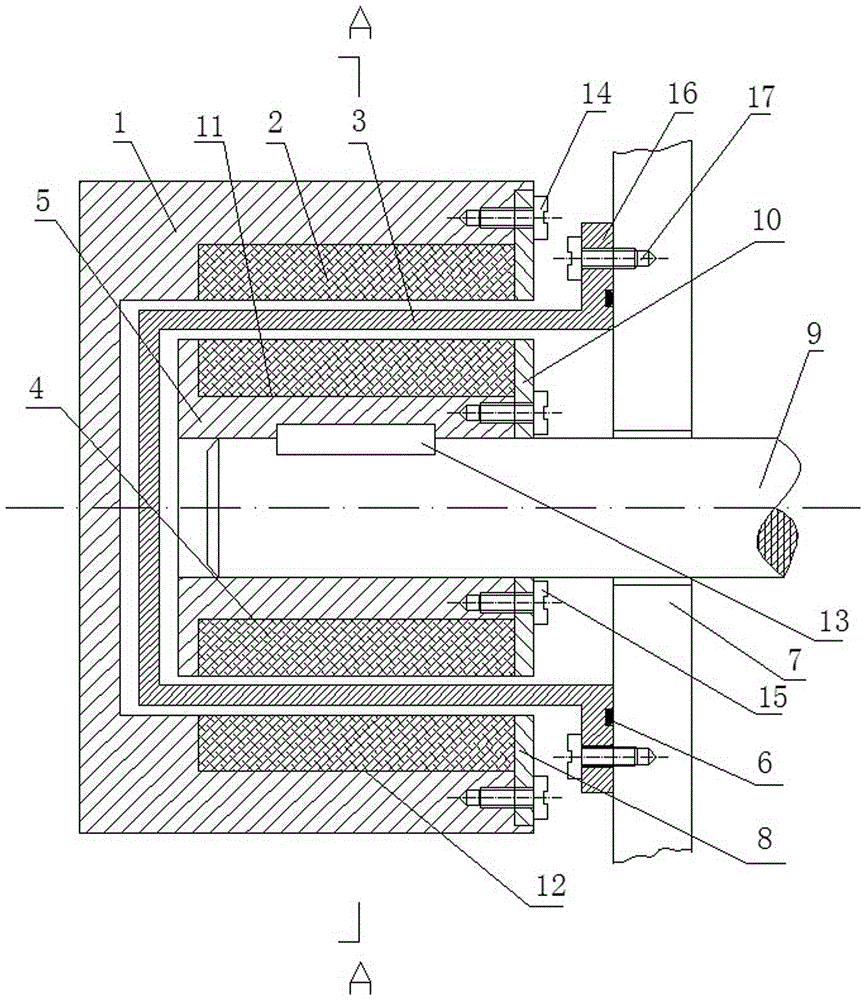

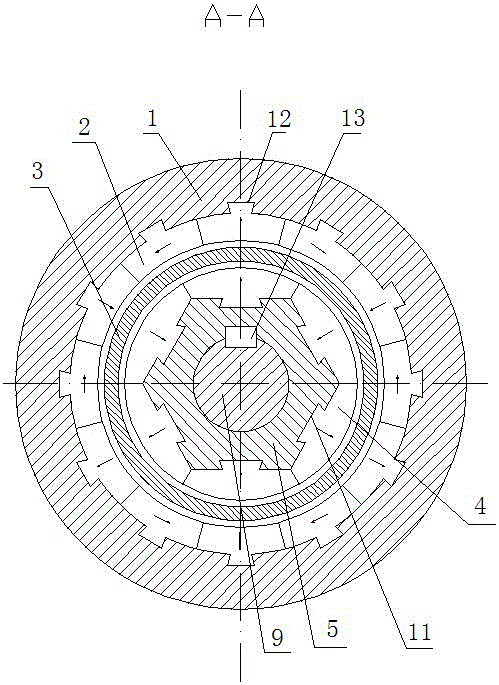

[0024] An inner closed radial flux magnetic force transmission mechanism for an underwater direct-drive propeller, which consists of: an outer rotor core 1, a plurality of outer rotor magnets 2, a spacer sleeve 3, a plurality of inner rotor magnets 4, an inner Rotor yoke 5, sealing ring 6, propeller end plate 7, outer rotor end plate 8, propeller prime mover shaft 9, inner rotor end plate 10,

[0025] The inner rotor yoke 5 is fixed with the prime mover shaft 9 of the propeller through the flat key 13, and one end of the outer surface of the inner rotor yoke 5 is processed with a plurality of dovetail grooves I11 in the axial direction. A plurality of dovetail slots I11 are evenly distributed along the outer surface of the inner rotor yoke 5, and a boss is provided at the middle of one end of each inner rotor magnet 4, and the boss of each inner rotor magnet 4 is matched with a fixed device. into the corresponding dovetail slot I11, the outer rings of the plurality of inner ro...

Embodiment 2

[0027] The inner closed radial flux magnetic force transmission mechanism for an underwater direct-drive thruster described in Embodiment 1, the inner rotor yoke 5 is a regular polygonal structure, preferably a regular hexagon, and the inner rotor yoke 5 Dovetail slot I11 is milled in the middle of each outer surface of the rotor, and the inner rotor yoke 5 is made of magnetically permeable metal material.

Embodiment 3

[0029] An internally closed radial flux magnetic force transmission mechanism for an underwater direct-drive propeller described in Example 1, the outer rotor core 1 is made of corrosion-resistant non-magnetic structural steel material, which avoids the use of traditional magnetic materials. The outer rotor is corroded due to exposure to water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com