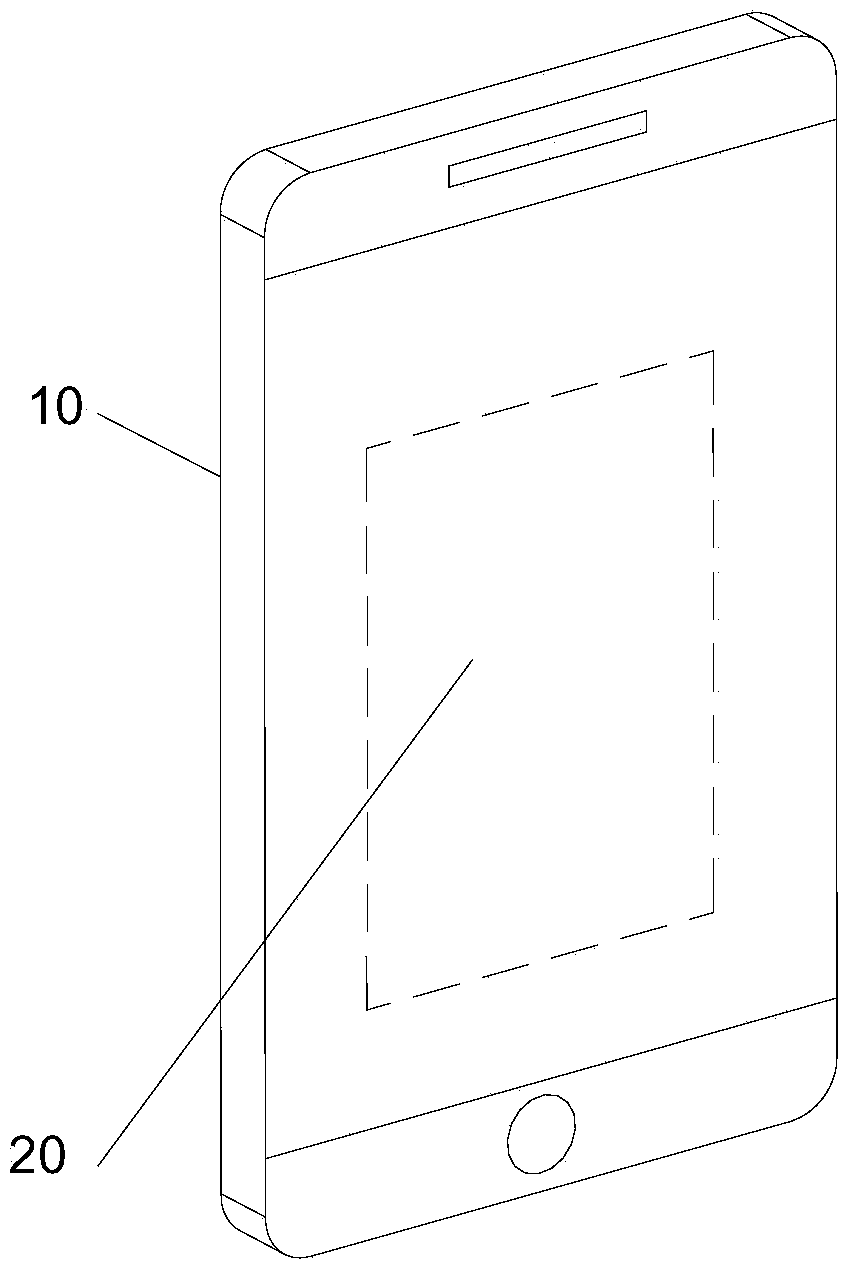

Electronic equipment, method for preparing electronic equipment casing, and stamping die

A technology for electronic equipment and stamping dies, which is applied in the field of workpiece stamping and can solve problems such as complex assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

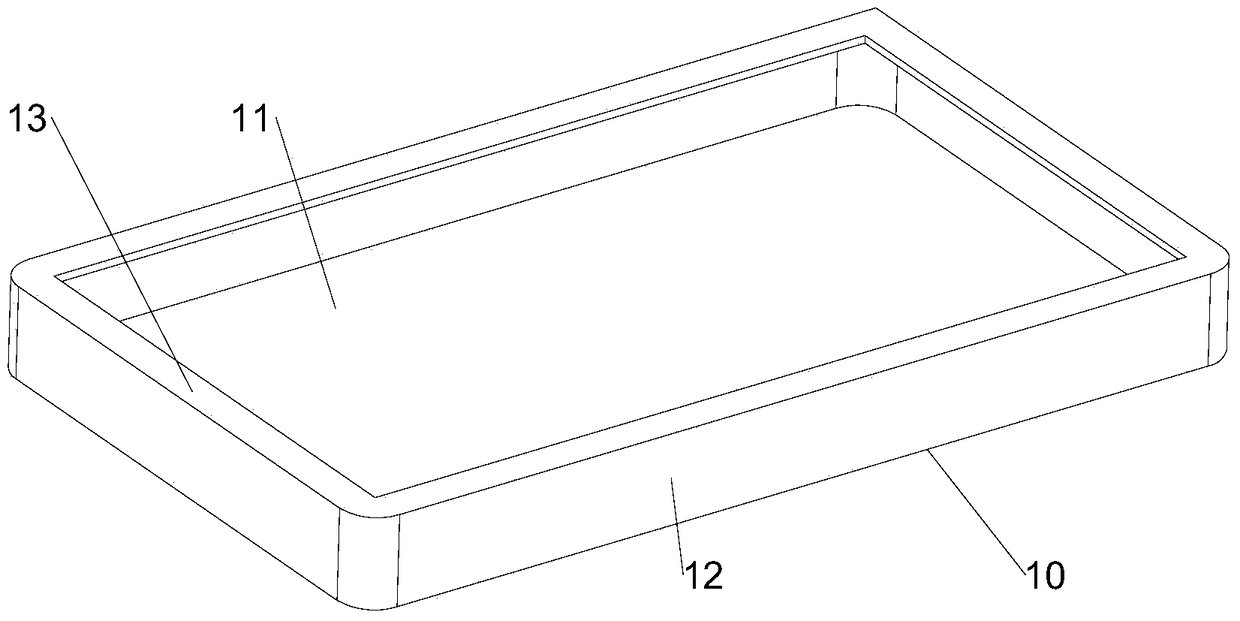

[0127] Such as Figure 4 As shown, the pre-processed part A10 includes a first side wall A1 extending from the outer edge of the bottom case 11 to the first direction, and the first side wall A1 includes: The first part A11 and the second part A12 connected in sequence in one direction.

[0128] Step 1: Manufacture a first semi-finished product B10 by processing the first side wall A1 of the pre-processed part A10, so that the second part A12 of the first semi-finished product B10 and the first part A11 form a second a predetermined angle.

[0129] The second step: by processing the second part A12 of the first side wall of the first semi-finished product B10, a second semi-finished product C10 is produced, and the first part 121 of the eaves is formed on the second semi-finished product C10, The outer surface of the first part 121 of the eaves intersects the outer surface of the first part A11 of the first side wall to form an intersection line 14, and the outer surface of ...

Embodiment approach 2

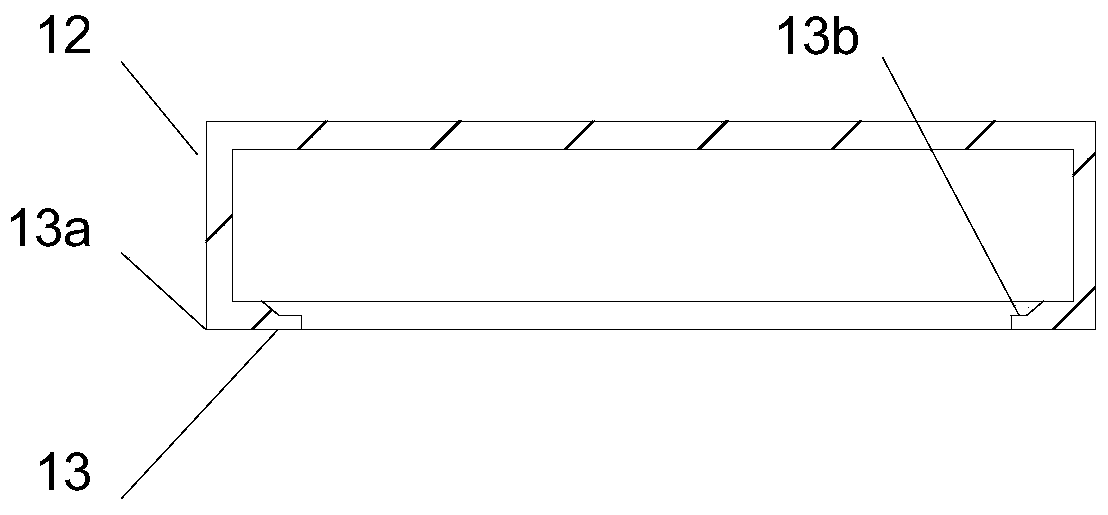

[0139] Such as Figure 5 As shown, the pre-processed part A10 includes a first side wall A1 extending from the outer edge of the bottom case 11 to the first direction, and the first side wall A1 includes: The first part A11 and the second part A12 connected in sequence in one direction.

[0140] Step 1: Manufacturing a third semi-finished product D10 by machining the second portion A12 of the first side wall A1 of the prefabricated part A10 such that the first portion of the eaves of the third semi-finished product D10 The outer surface of the eaves 121 intersects the outer surface of the first part A11 of the first side wall to form an intersection line 14, and the outer surface of the first part 121 of the eaves and the first part A11 of the first side wall The outer surface is at right angles.

[0141] The second step: by processing the remaining part 122 of the second part of the first side wall of the third semi-finished product D10 except the first part of the eaves 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com