Linear-motor-driven conveying system, in particular stretching system

A technology of linear motors and conveying equipment, applied in the field of stretching equipment in the form of synchronous stretching equipment, can solve problems such as damage to supports, uncertain motion states, vibration, etc., and achieve the goals of reducing energy demand, avoiding vibration, and reducing structural height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

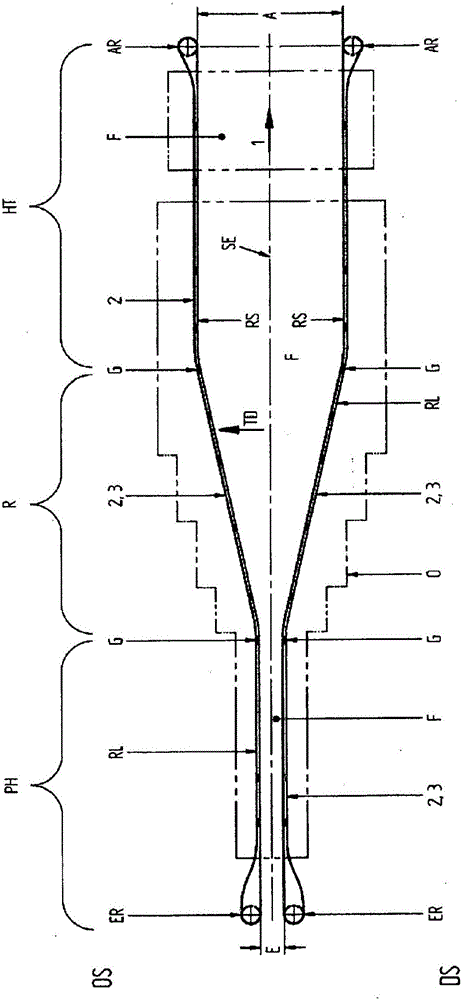

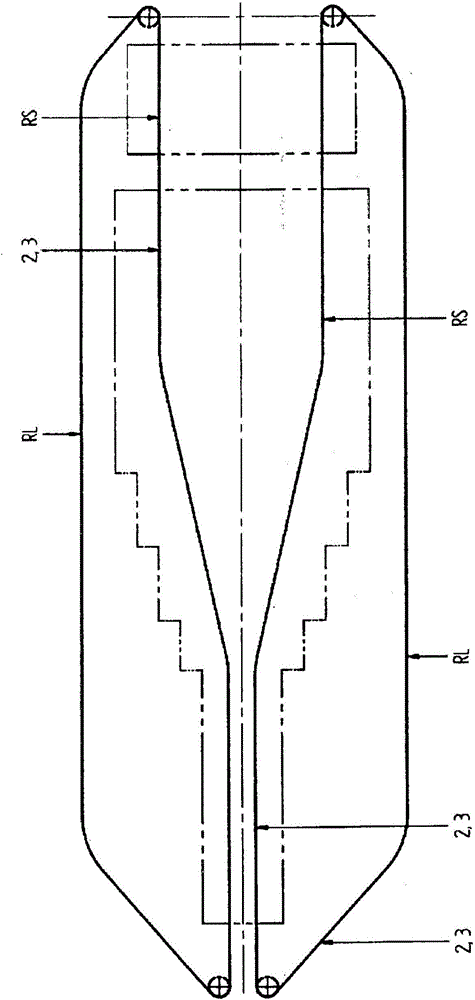

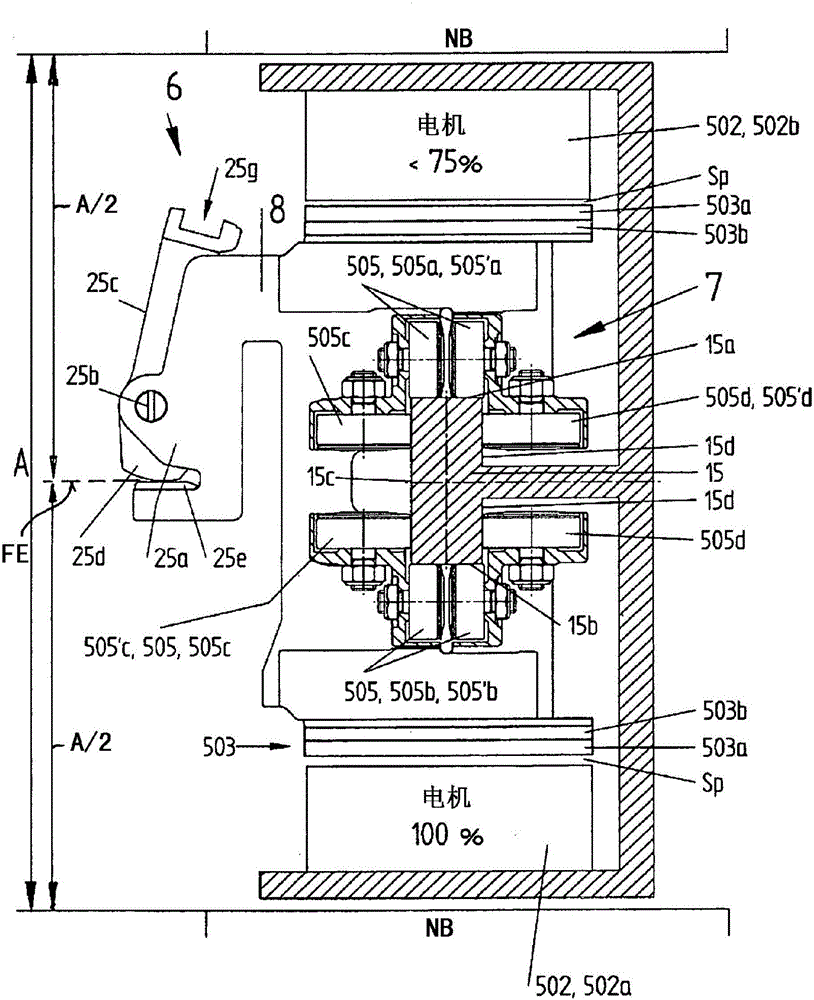

[0052] The linear motor-driven conveying device is described below based on a synchronous stretching device.

[0053] Such a stretching device has two symmetrically formed drive systems, which are symmetrical with respect to a central plane of symmetry SE extending perpendicularly to the plane of the drawing. exist Figure 1a Two drive systems arranged along the drawing direction 1 symmetrically with respect to the symmetry plane SE are drawn in , wherein the material web to be processed, that is to say stretched, in particular in the form of a plastic film F, is arranged at two positions along the drawing direction 1 The drive system that surrounds on the closed track 2 moves through.

[0054] Unstretched film F (only film will be described below, although processing web F can generally be handled with this stretching device and can be simultaneously stretched longitudinally and transversely, so that the invention is therefore not limited to plastic film webs ) enters the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com