Scanning path planning method for manufacturing three-dimensional body layer by layer and scanning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

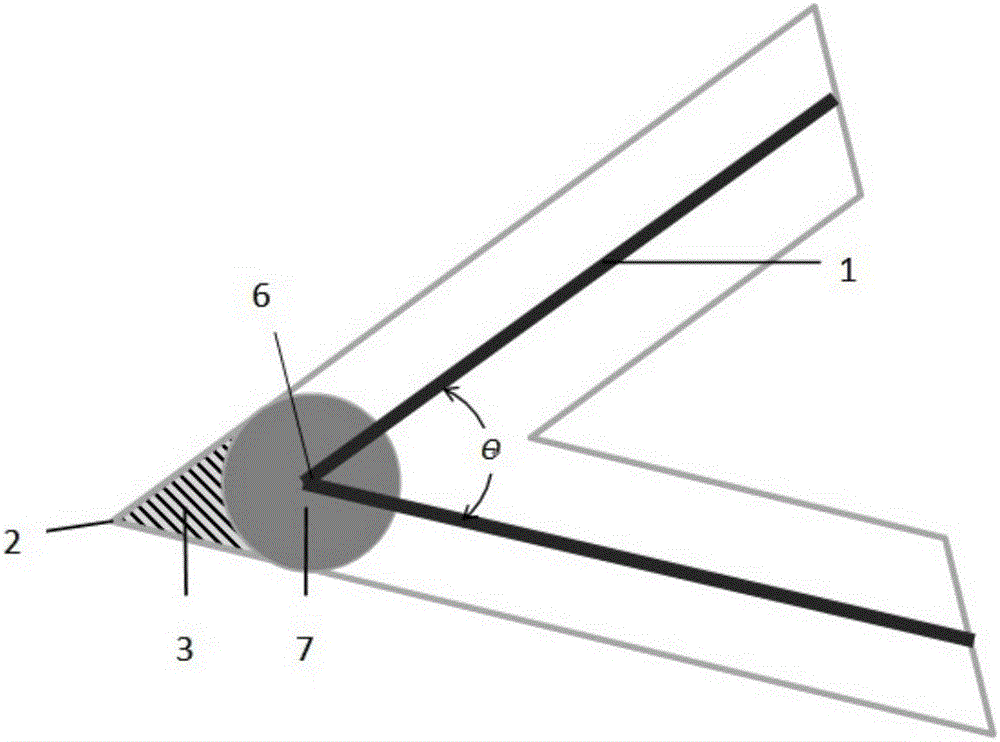

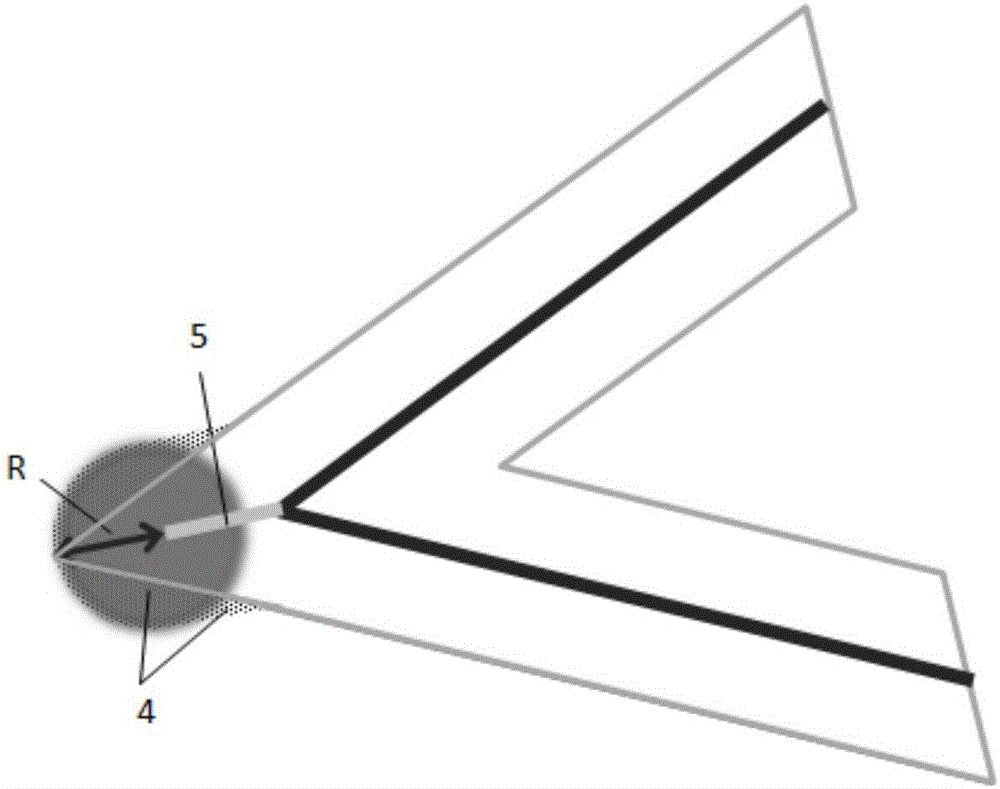

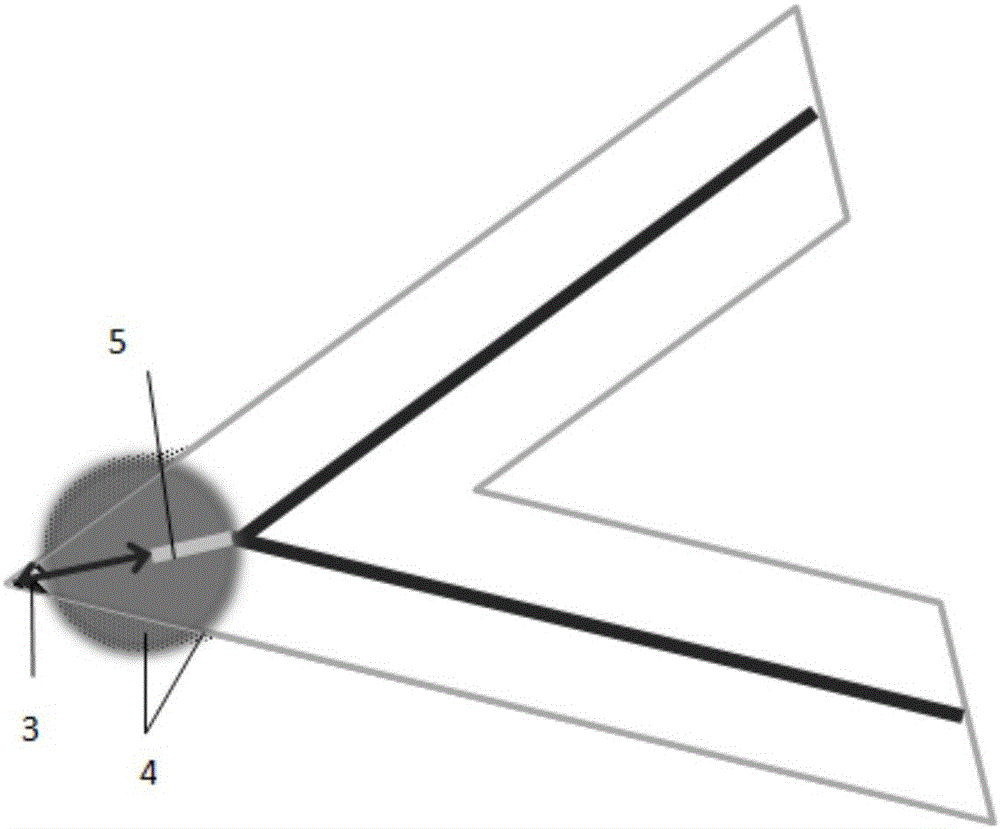

[0038] A scanning path planning method for manufacturing three-dimensional objects layer by layer according to the present invention, the specific implementation steps are as follows: figure 2 As shown, a compensation path 5 is added between the jump point 6 of the conventional scanning path and the vertex 2 of the sharp corner of the three-dimensional object section at the sharp corner of the three-dimensional object section with sharp corners, wherein, the compensation path 5 starts at the sharp corner of the three-dimensional object section The jumping point 6 of the conventional scanning path is the starting point, pointing to the direction of the sharp corner apex 2 of the section of the three-dimensional object, and its length is equal to the distance between the jumping point 6 of the conventional scanning path at the sharp corner of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com