Cutting device for sectional materials

A technology for cutting devices and profiles, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low profile cutting efficiency and poor profile cutting quality, and achieve easy operation and improved safety , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

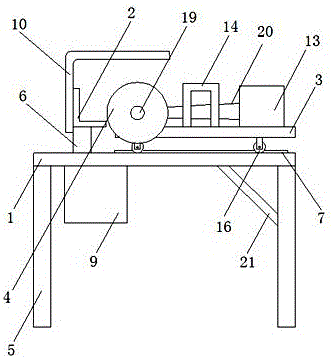

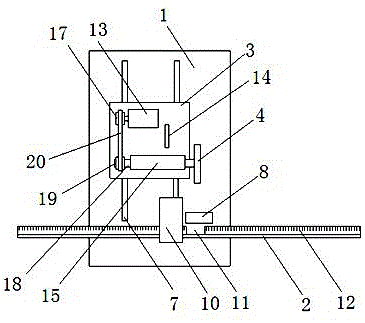

[0014] as attached figure 1 and 2 Shown: a cutting device for profiles, including an operating table 1, a backing plate 2, a moving plate 3 and a cutting wheel 4, characterized in that: the operating table 1 is set on a bracket 5, and on the operating table 1 A fixed block 6, a guide rail 7, a chip discharge port 8, and a chip collection box 9 are arranged on the top, and a reinforcing rod 21 is arranged between the console 1 and the bracket 5, and the gap between the console 1 and the bracket 5 is improved by the reinforcing rod 21. The strength of the connection between them improves the strength of the cutting device. The chip outlet 8 and the chip box 9 on the console 1 can collect the chips in a concentrated manner, which improves the environmental protection performance. The backing plate 2 is arranged on the fixed block 6, and a protective cover 10, a cutout 11, and a scale 12 are arranged on the backing plate 2. The backing plate 2 is set in an L-shaped structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com