A three-degree-of-freedom robot for batch flipping of wine bottles

A robot and degree of freedom technology, applied in the direction of conveyors, manipulators, conveyor objects, etc., can solve the problems of insufficient precision structure, expensive equipment, high price, etc., and achieve the effect of ensuring position accuracy, position accuracy, and stable posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

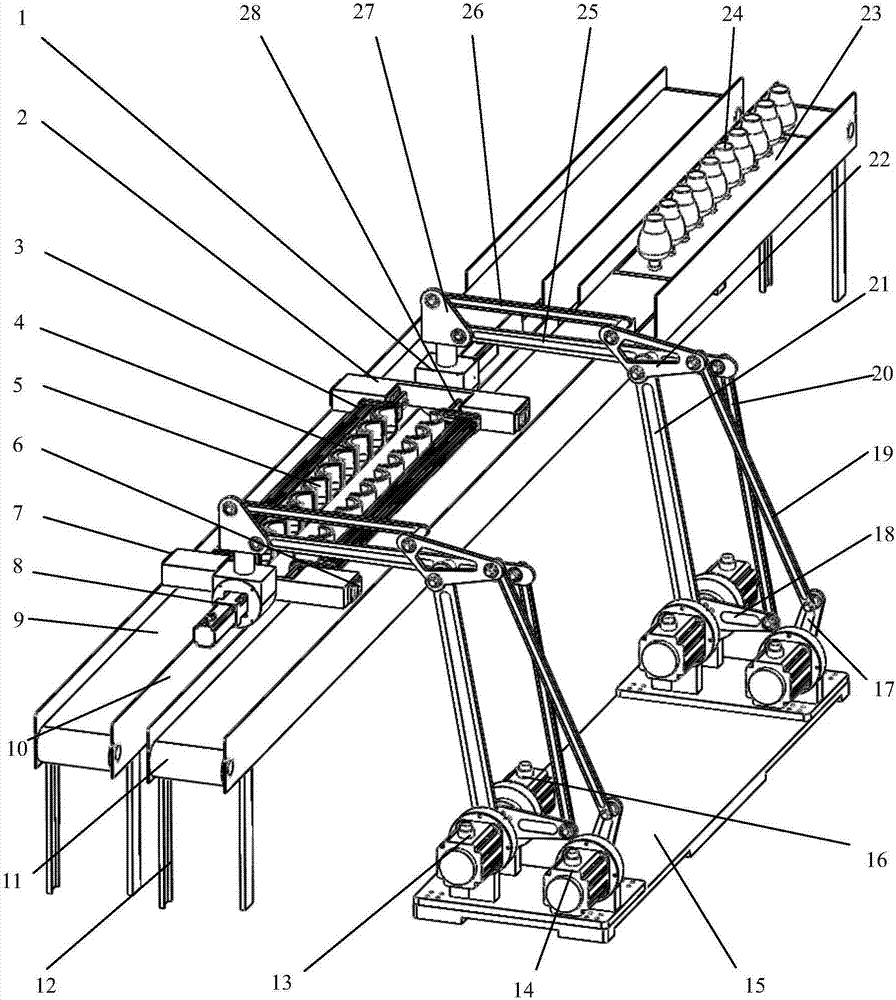

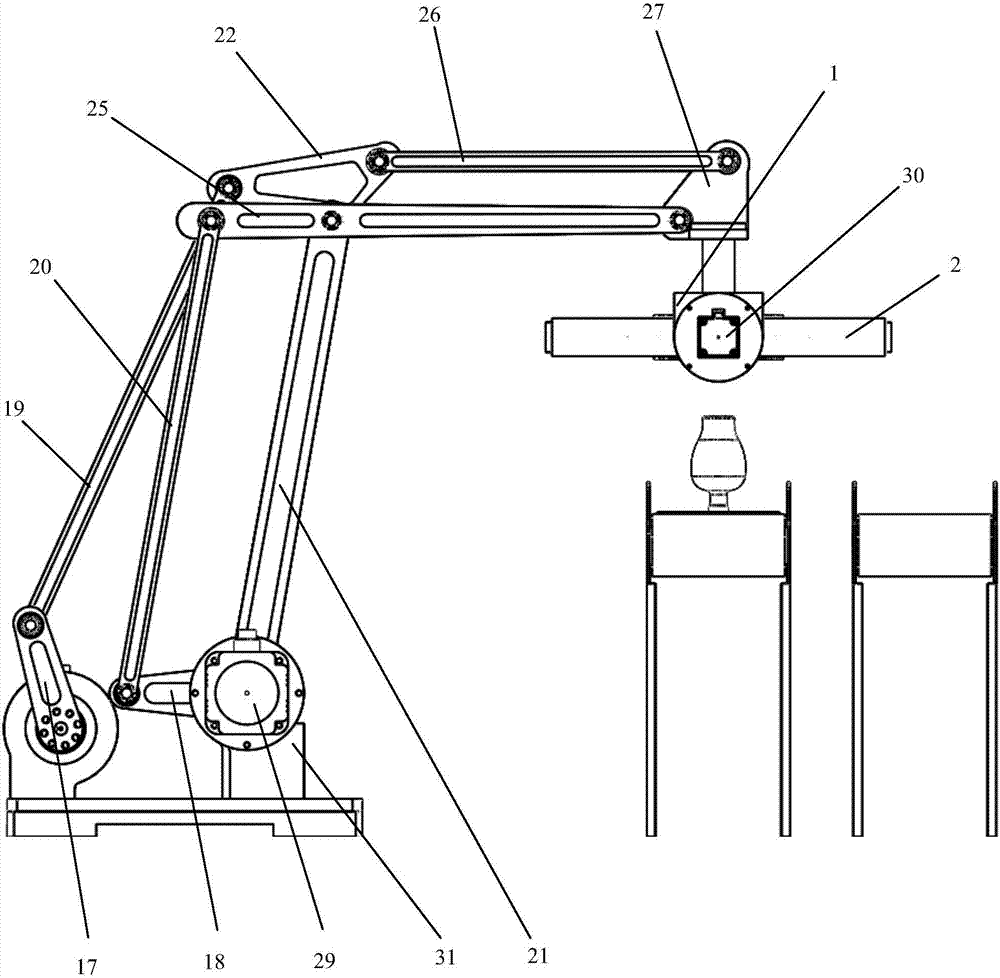

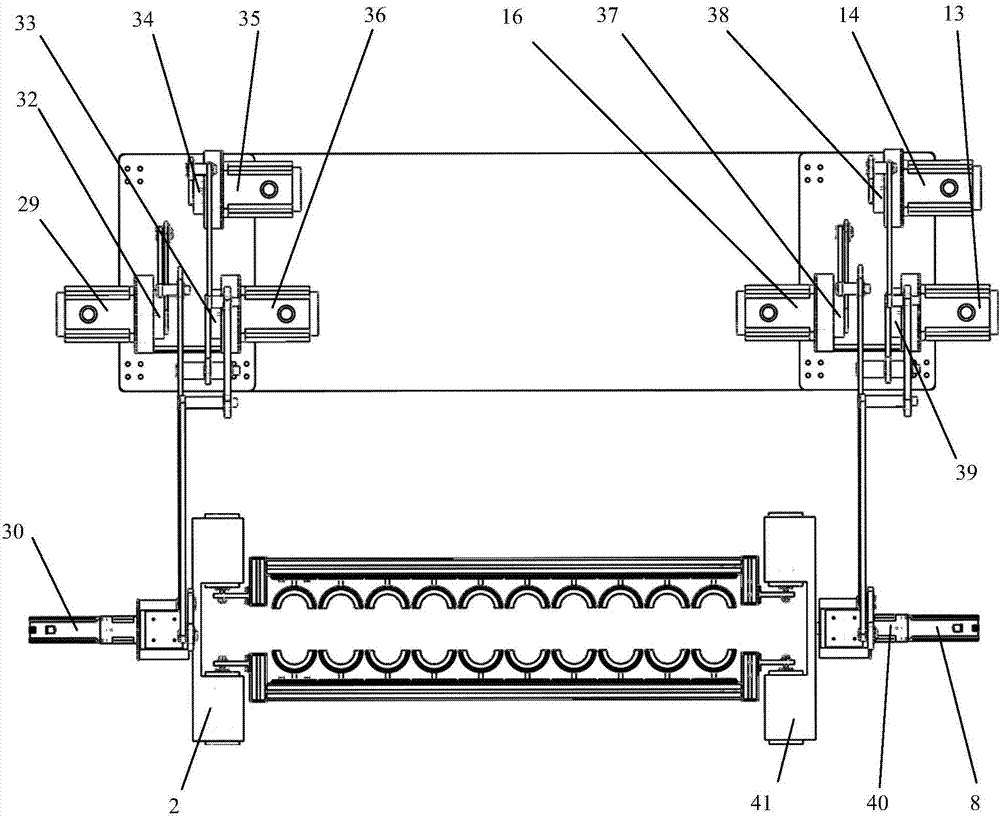

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a three-degree-of-freedom robot for batch turning of wine bottles provided by the present invention includes a fixed frame 15, a turning device, two sets of identical driving branch chains and conveyor belt devices. The two sets of driving branch chains work together to provide two degrees of translational freedom for the turning device.

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the drive branch chains are connected to each other through a rotating hinge and a rotating pair formed between the bearing and the shaft.

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the drive branch chain includes a fixed frame 15, a nodding flange 17, an attitude maintaining bar 19, a small arm 18, a small arm pull bar 20, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com