Multi-station rotational forming machine

A molding machine and multi-station technology, which is applied in the field of injection blowing or injection stretch blowing plastic bottle manufacturing equipment, can solve the problems of limited output of molding machines, expansion of floor space, and increase of equipment volume, so as to shorten the processing cycle and increase the output. , the effect of reducing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

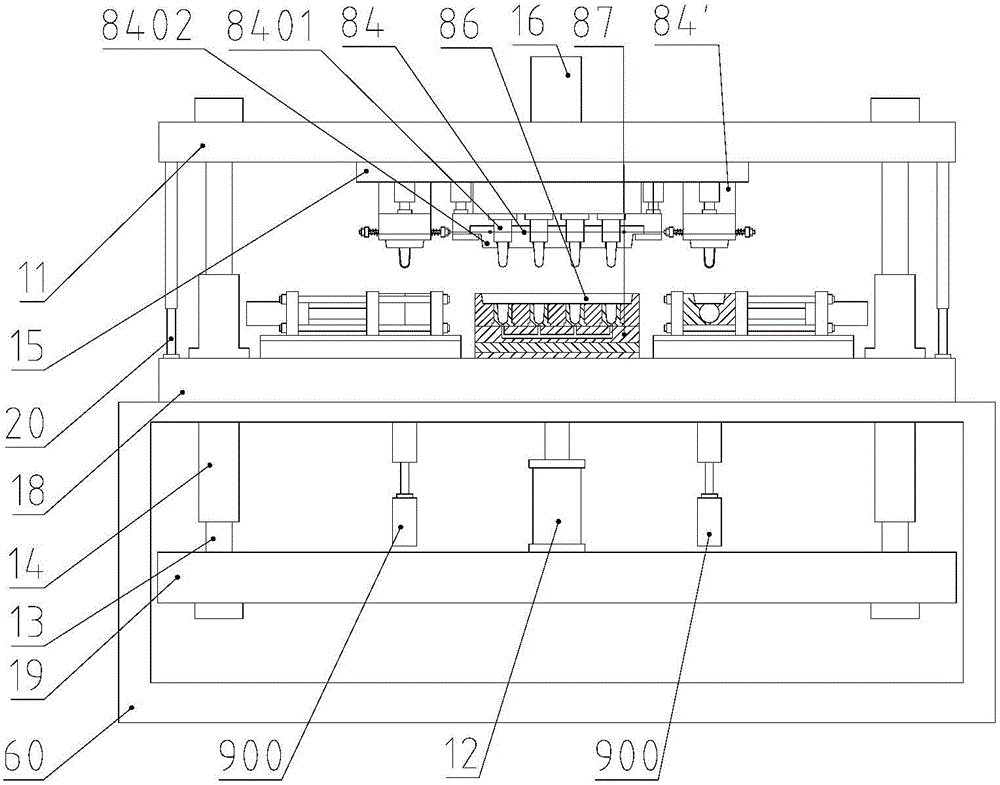

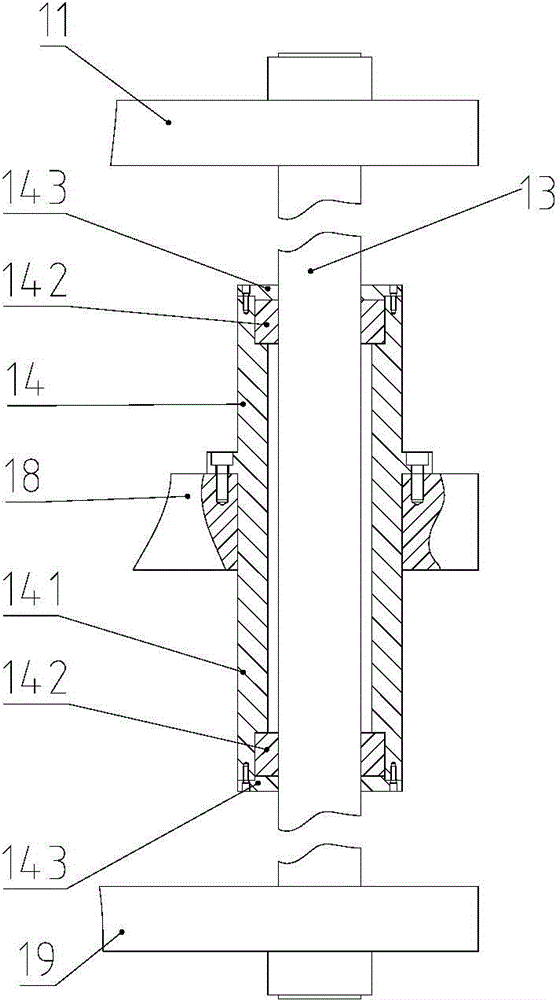

[0036] figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 for figure 1 side view. Such as figure 1 and combine figure 2 As shown, the present invention provides a multi-station rotary molding machine. In this embodiment, the injection blowing equipment is taken as an example to describe the technical solution in detail. Specifically, the multi-station rotary molding machine includes a main machine and an injection mold set and a blow molding set arranged on the main machine; the main machine includes a frame 60 and a workbench panel 18 arranged above the frame 60, and The workbench panel 18 is horizontally fixed on the frame 60 , the workbench panel 18 is connected with the lower formwork 19 through the clamping oil cylinder 12 , and the lower formwork 19 is connected with the upper formwork 11 through the guide column 13 passing through the workbench 18 vertically. More specifically, the bottom surface of the workbench panel ...

Embodiment 2

[0050] Figure 16 It is a schematic diagram of the structure of the double-row mold in the second embodiment of the present invention. In the first embodiment above, the molds arranged on the injection mold set and the blow molding set are arranged in a single row. For products with greater output requirements, such as Figure 16 As shown, double or multi-row arrangements are also possible. The difference between this embodiment and the first embodiment lies in the arrangement of the molds on the injection mold and the blowing mold. Other technical features are the same as those of the first embodiment. For details, please refer to the first embodiment, which will not be repeated here.

Embodiment 3

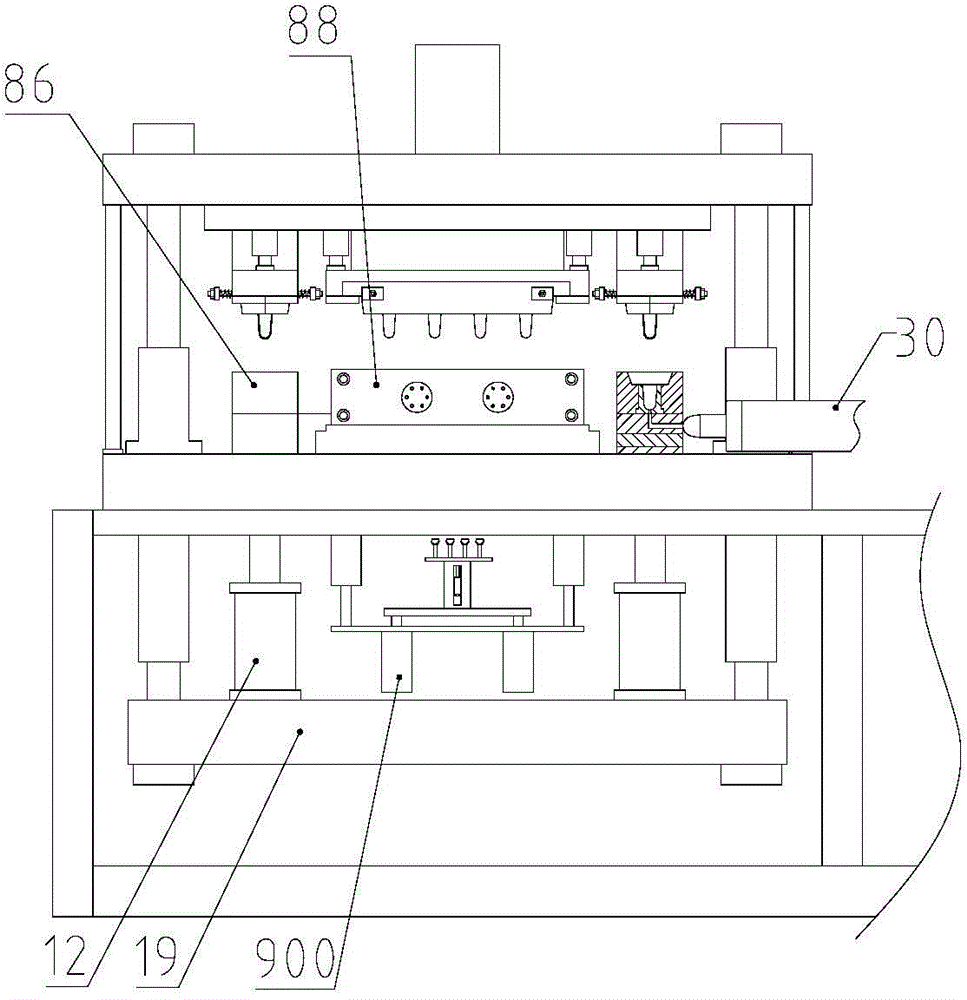

[0052] Figure 17 A schematic diagram of the overall structure of Embodiment 3 of the present invention. Such as Figure 17 As shown, in addition to the structures of the above two embodiments, in fact, on the premise that the space for the rotating disk 15 is allowed, in order to further increase the output, the number of injection molds and blow molds can be set more, Those skilled in the art can make reasonable structural settings according to actual needs. In this embodiment, the number of the injection mold group and the blow mold group is three groups, such as Figure 17 Shown in is the setting position structure of the concave mold group 86 and the blow mold group 88 on the workbench panel 18, as Figure 17 It can be seen that the setting interval angle between two adjacent modules is 60°. control figure 1 As shown, six sets of die sets 84 can be correspondingly arranged on the rotating disk 15, and the interval angle between two adjacent die sets 84 is 60°.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com