Ink filling machine and ink filling method for recycled ink cartridge

An ink filling machine and ink cartridge technology, applied in printing and other fields, can solve problems affecting the utilization of recycled ink cartridges, insufficient product qualification rate, complex internal structure, etc., to solve the problem of gas and liquid on-off, avoid printing defects, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

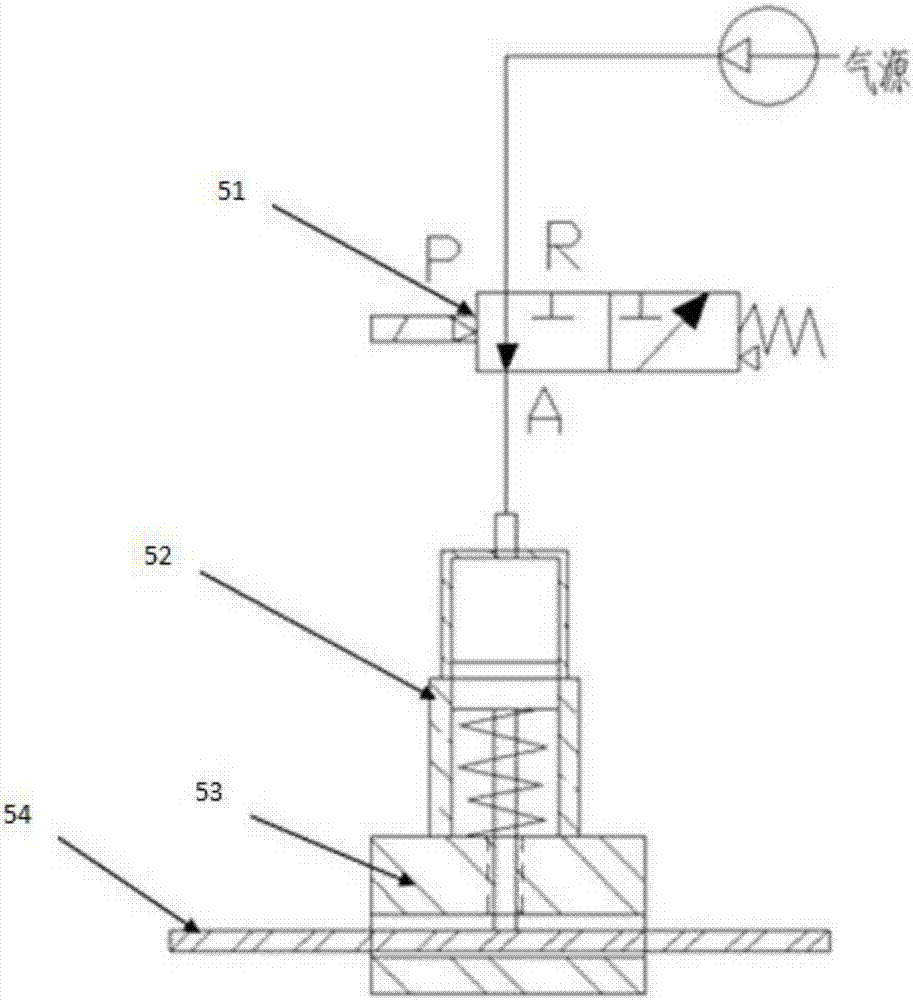

[0053] The ink filling method includes the following steps:

[0054] Step 1: Connect the ink filling machine to the cartridge body, close the first on-off valve, open the second on-off valve and the third on-off valve, and vacuum the interior of the cartridge body for 1S;

[0055] Step 2: Close the second on-off valve and the third on-off valve, open the first on-off valve, and inject the ink of the ink container into the ink cartridge through the ink injection port under the action of air pressure and keep it for 1S until the ink fills the ink cartridge;

[0056] Step 3. Close the first on-off valve and separate the ink refilling port from the ink refilling port of the ink cartridge, and then open the second on-off valve, hold it for 1 second, close the second on-off valve, and discharge the ink outlet from the ink cartridge Mouth separation

[0057] Step 4. Seal the ink filling port and ink outlet of the ink cartridge.

Embodiment B

[0059] The ink filling method includes the following steps:

[0060] Step 1. Connect the ink filling machine to the cartridge body, close the first on-off valve, open the second on-off valve and the third on-off valve, and vacuum the inside of the cartridge body for 30 seconds;

[0061] Step 2: Close the second on-off valve and the third on-off valve, open the first on-off valve, and inject the ink of the ink container into the ink cartridge through the ink injection port under the action of air pressure and keep it for 30S until the ink fills the ink cartridge;

[0062] Step 3. Close the first on-off valve and separate the ink refilling port from the ink refilling port of the ink cartridge, then open the second on-off valve, hold it for 30S, close the second on-off valve, and discharge the ink outlet from the ink cartridge Mouth separation

[0063] Step 4. Seal the ink filling port and ink outlet of the ink cartridge.

Embodiment C

[0065] The ink filling method includes the following steps:

[0066] Step 1: Connect the ink filling machine to the cartridge body, close the first on-off valve, open the second on-off valve and the third on-off valve, and vacuum the interior of the cartridge body for 10 seconds;

[0067] Step 2: Close the second on-off valve and the third on-off valve, open the first on-off valve, and inject the ink of the ink container into the ink cartridge through the ink injection port under the action of air pressure and keep it for 15 seconds until the ink fills the ink cartridge;

[0068] Step 3. Close the first on-off valve, and separate the ink refilling port from the ink refilling port of the ink cartridge, and then open the second on-off valve, keep it for 20 seconds, close the second on-off valve, and discharge the ink outlet from the ink cartridge Mouth separation

[0069] Step 4. Seal the ink filling port and ink outlet of the ink cartridge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com