Air pressure feeding device

A feeding device and air pressure technology, applied in the field of air pressure feeding mechanism, can solve the problems of high manufacturing and maintenance costs, numerous parts, complex structure, etc., achieve the effects of simplified structure, simple and practical mechanism structure, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

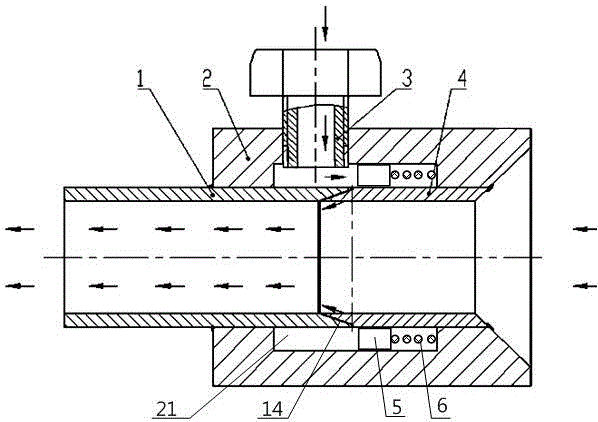

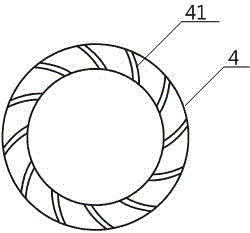

[0010] Such as figure 1 Shown is a pneumatic feeding device, comprising an inner cone sleeve 1 communicated with the material input end, an outer cone sleeve 4 communicated with the material output end, and the left end surface of the outer cone sleeve 4 has a section of outer truncated cone 12 corrugated protrusions 41 are provided on the conical surface, and the right end surface of the inner cone sleeve 1 has a section inner truncated conical surface, and its taper is the same as the angle of the truncated conical surface of the outer cone sleeve 4; The shape protrusion 41 makes the gap 14 formed between the inner cone sleeve 1 and the outer cone sleeve 4; the inner cone sleeve 1 and the outer cone sleeve 4 are sealed with an outer sleeve 2, and the outer sleeve 2 is in the corresponding A cavity 21 is set at the gap 14, and a pipe fitting 3 connecting the outlet end of the high-pressure air pump with the cavity 21 is also set on the outer sleeve 2; a piston 5 is also set i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com