Method for baking fine-particle-structure graphite product with open ring type furnace and graphite product obtained by method

A technology of graphite products and fine particles is applied in the field of graphite material manufacturing and processing, which can solve the problems of low yield and easy cracking, and achieve the effects of saving roasting cost, improving thermal energy utilization rate and high bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Round carbon products with a specification of φ550mm are roasted for the first time in an open-ring roasting furnace. The steps are as follows:

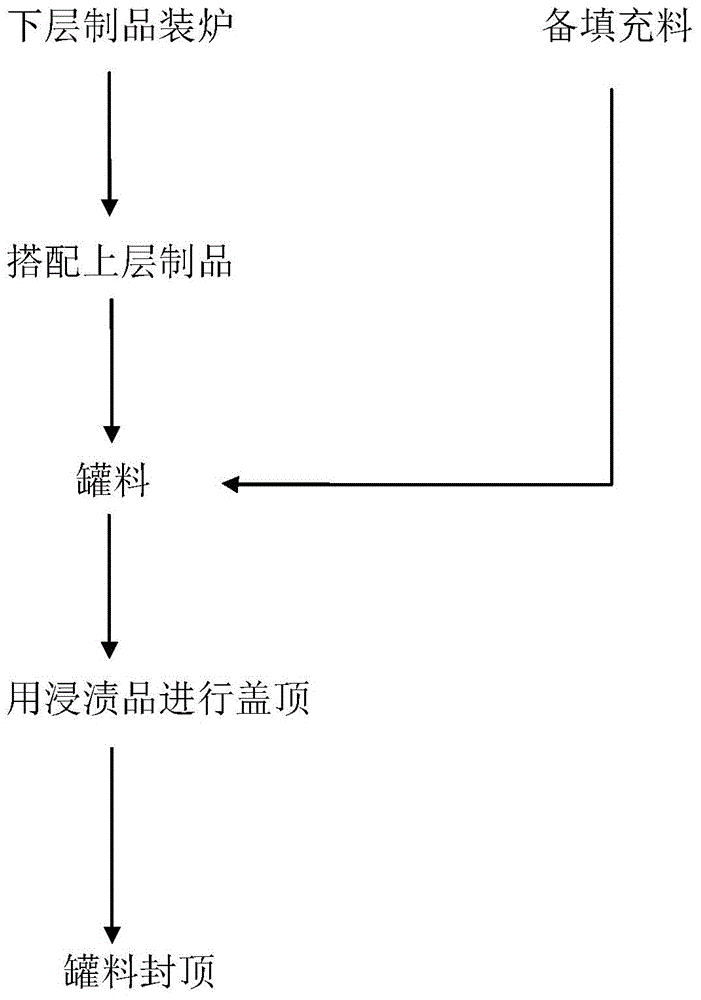

[0022] 1) Furnace installation:

[0023] Furnace products: round carbon products with a specification of φ550mm.

[0024] Filler: A filler whose mass ratio is metallurgical coke: quartz sand=5.5:4.5.

[0025] Furnace loading operation: The furnace is loaded according to the conventional furnace loading operation. (For conventional furnace loading operations, please refer to "Carbon Technology", Metallurgical Industry Press, 2012 edition, edited by Jiang Wenzhong)

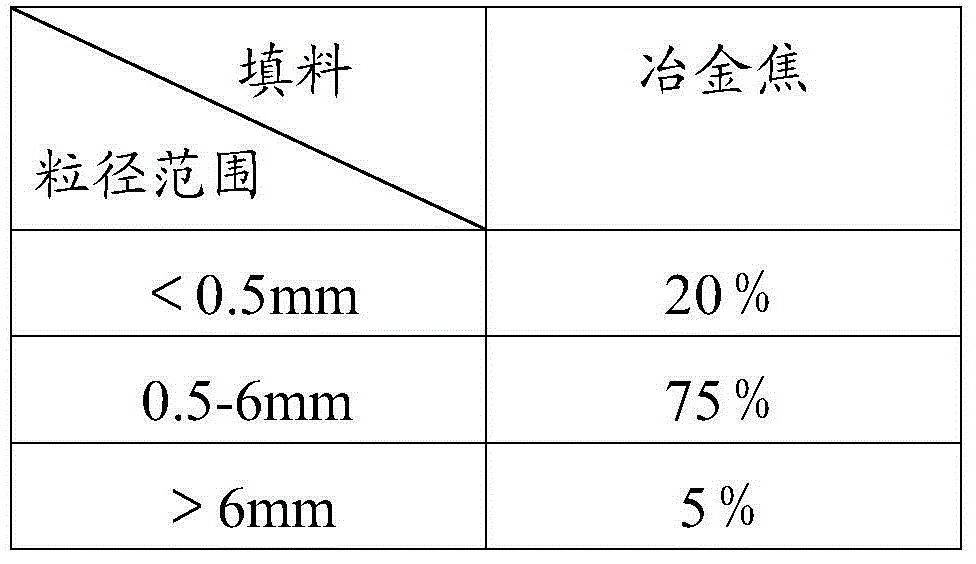

[0026] The specifications of quartz sand in the filler are not particularly limited. The particle size range of metallurgical coke and their respective proportions are shown in the following table:

[0027]

[0028] 2) Start the heating program and set the heating curve of the heating process as follows: at 150-350℃, the heating rate is 1.5℃ / h; at 350-600℃, the heating rate i...

Embodiment 2

[0032] A round carbon product with a specification of φ1100mm is roasted for the first time in an open ring roasting furnace. The steps are as follows:

[0033] 1) Furnace installation:

[0034] Furnace products: round carbon products with a specification of φ1100mm.

[0035] Filler: A filler whose mass ratio is metallurgical coke: quartz sand=7.5:2.5.

[0036] Furnace loading operation: The furnace is loaded according to the conventional furnace loading operation. (For conventional furnace loading operations, please refer to "Carbon Technology", Metallurgical Industry Press, 2012 edition, edited by Jiang Wenzhong)

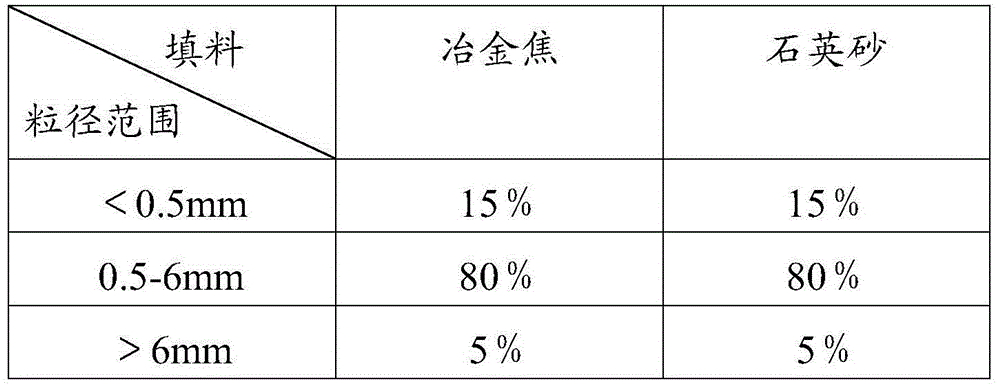

[0037] The particle size range of metallurgical coke and quartz sand in the filler and their respective proportions are shown in the following table:

[0038]

[0039] 2) Start the heating program and set the heating curve of the heating process as follows: at 150-350℃, the heating rate is 1.2℃ / h; at 350-600℃, the heating rate is 0.7℃ / h; at 600-750℃ When the temperature ri...

Embodiment 3

[0043] The carbon block product with a size of 450mm×550mm is roasted for the first time in an open ring roasting furnace. The steps are as follows:

[0044] 1) Furnace installation:

[0045] Furnace products: square products with a size of 450mm×550mm.

[0046] Filler: mass ratio is a mixture of metallurgical coke: quartz sand=7:3.

[0047] Furnace loading operation: Place the first roasted raw carbon block in the lower layer of the furnace, and place the second or multiple roasted carbon blocks on the upper layer, and ensure that the distance between the carbon products is maintained at about 50mm. Finally, the impregnated product is loaded to protect the production exhaust.

[0048] The particle size range of metallurgical coke and quartz sand in the filler and their respective proportions are shown in the following table:

[0049]

[0050] 2) Start the heating program, and set the heating curve of the heating process as follows: at 150-350℃, the heating rate is 1.5℃ / h; at 350-600℃, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com