Negative electrode active material for lithium ion secondary battery, negative electrode for lithium ion secondary battery using the same, and lithium ion secondary battery

A negative electrode active material, secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem of increasing the volume density of electrodes containing active materials, and achieve the effect of excellent performance balance and improved volume density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Lump coke (green coke) produced by delayed coking method using refined pitch from coal-based heavy oil from which quinoline insoluble components have been removed and heat-treated at 500°C for 24 hours is performed by orient mill and jet mill Finely pulverize to obtain the average particle size (D 50 ) is a green coke sheet (finely pulverized green coke) of 10.5 μm.

[0056] The green coke pieces obtained as described above were calcined in a low-oxygen atmosphere from 700° C. near the inlet to 1500° C. near the outlet (the highest reaching temperature) for more than one hour in a rotary kiln to obtain calcined coke. The calcined coke is finely pulverized using the same jet mill as above, and the processing amount per unit time and the gas flow rate during processing are appropriately adjusted, and then most of the fine powder below 3 μm is removed by air classification, thereby obtaining the true specific gravity. 2.15g / cm 3 、D 10 3.7μm, D 50 10.2μm, D 90 19.7μm, ...

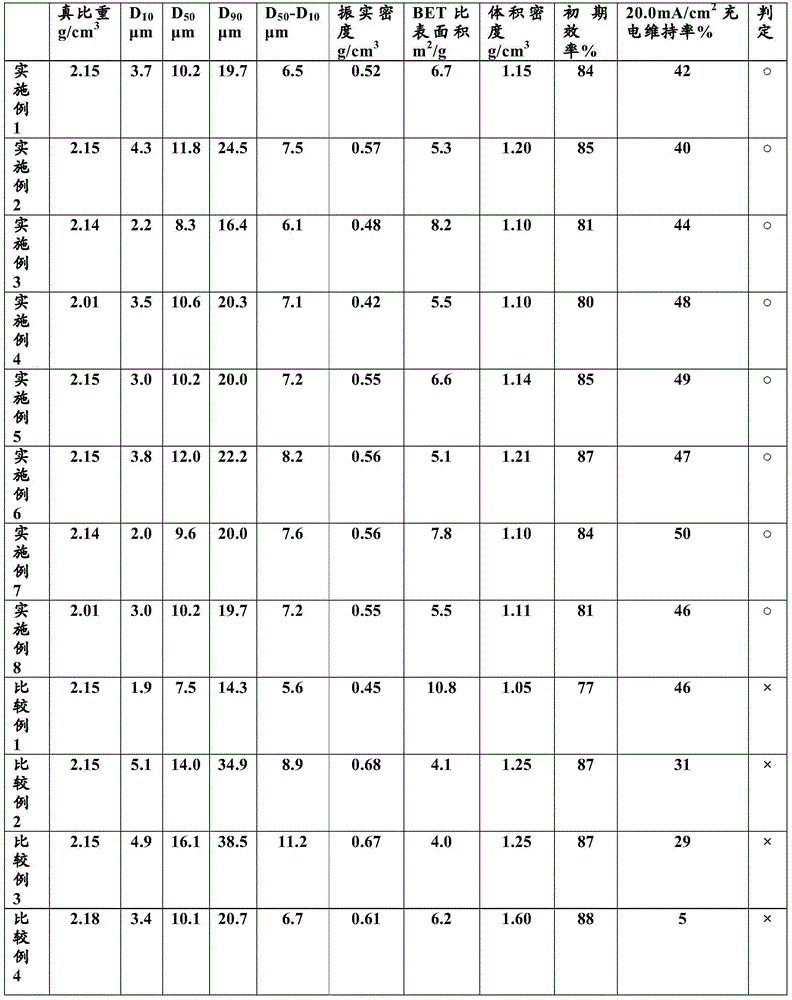

Embodiment 2~3、 comparative example 1~3

[0063] Except changing the conditions at the time of jet mill pulverization after obtaining calcined coke, the same operation as Example 1 was performed respectively, and the negative electrode active material for lithium ion secondary batteries which differs in particle size distribution as shown in Table 1 was obtained. Table 1 shows the characteristics of the obtained negative electrode active material. In addition, as a result of observing the cross-section of the electrode prepared in the same manner as in Example 1, it was confirmed that the active material particles corresponding to the ellipse with an aspect ratio in the range of 0.05 to 0.70 were 85 to 89% in all samples. Using these particles, a negative electrode and a lithium ion secondary battery were obtained in the same manner as in Example 1, and the charge retention ratio was investigated for each. The results are shown in Table 1.

Embodiment 4

[0065] Using a rotary kiln, calcined green coke pieces in a low-oxygen atmosphere from a temperature near the inlet of 700°C to a temperature near the outlet of 1000°C (the highest temperature) for more than 1 hour to obtain calcined coke. 1 The same operation was performed to obtain a lithium-ion secondary battery. Table 1 shows the characteristics of the obtained negative electrode active material. In addition, as a result of observing the cross-section of the electrode produced in the same manner as in Example 1, it was confirmed that 90% of the active material particles corresponded to an ellipse having an aspect ratio in the range of 0.05 to 0.70. In addition, the charge maintenance rate and initial efficiency were investigated in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com