Method and device for assisting laser cladding through ultrasonic vibration-magnetic stirring composite energy field

A technology of ultrasonic vibration and composite energy field, applied in metal material coating process, coating and other directions, can solve problems such as unsatisfactory effect and single function, and achieve the effect of strong engineering application value, flexible regulation and sufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

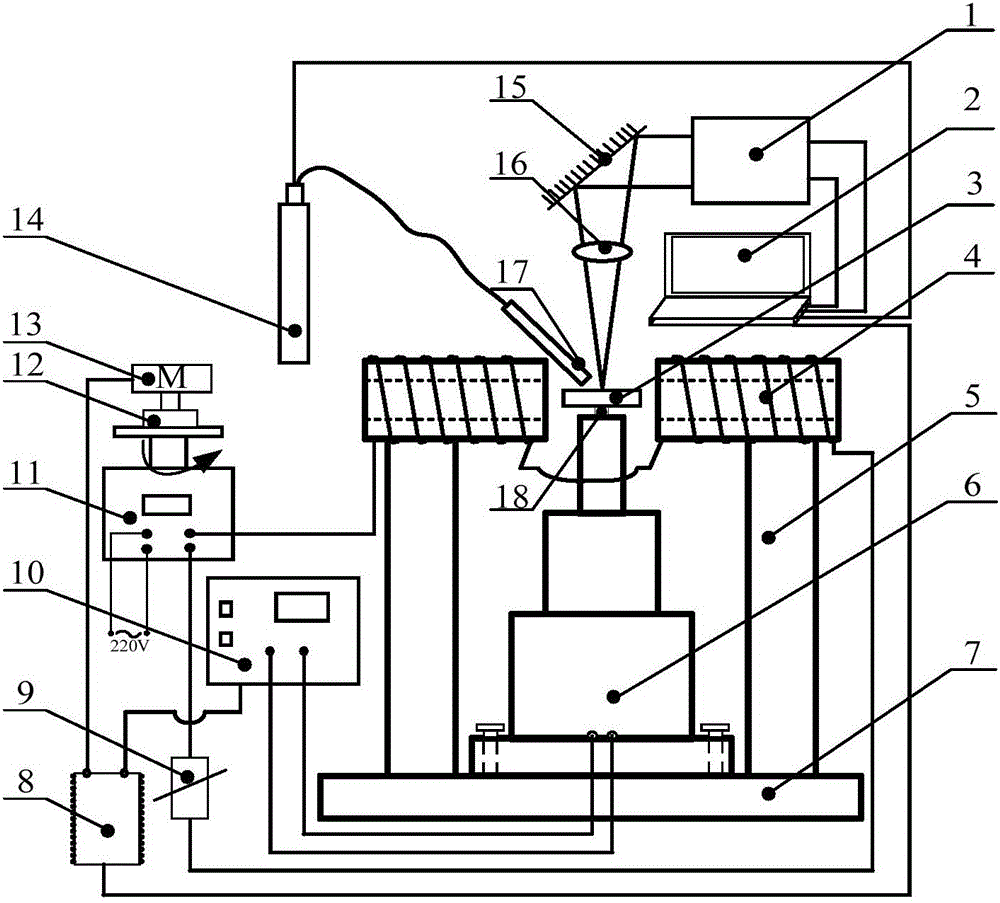

[0040] A kind of ultrasonic vibration-electromagnetic stirring composite energy field assisted laser cladding method, it comprises the following steps:

[0041] (1) Use the preset method to pre-spread the required powder on the cladding substrate by means of binder or powder tableting, and place it in a vacuum drying oven to dry;

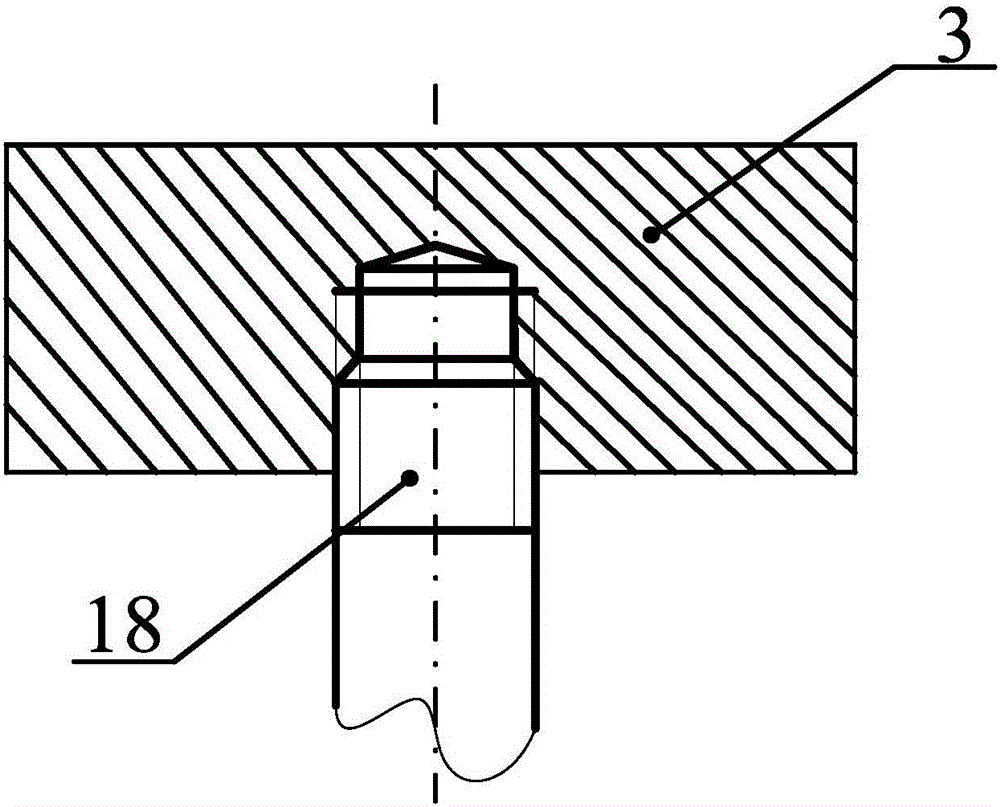

[0042] (2) Connect the dried cladding matrix with pre-set powder to the ultrasonic vibration device through a threaded rod, and place it horizontally at the center of the coaxial lines of the two excitation coils;

[0043] (3) Adjust the frequency and power of the ultrasonic power supply so that the cladding substrate with the pre-set powder produces an amplitude of 0.1-50 μm and a vibration frequency of 20-80 kHz. At the same time, the electronic voltage regulator is automatically adjusted to make the current in the circuit in the 3-20A is adjustable, and an alternating magnetic field of 9.7-65.7mT is generated in the cladding area;

[0044] (4) T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap