Vertical loading method for simulating pile sinking process of static pressure pile

A technology of vertical loading and static pressure piles, which is applied in the field of vertical loading for simulating the process of static pressure pile sinking, and the field of loading devices for simulating the process of static pressure pile sinking, which can solve the problems of poor vertical loading accuracy and achieve vertical loading , accurate test data and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

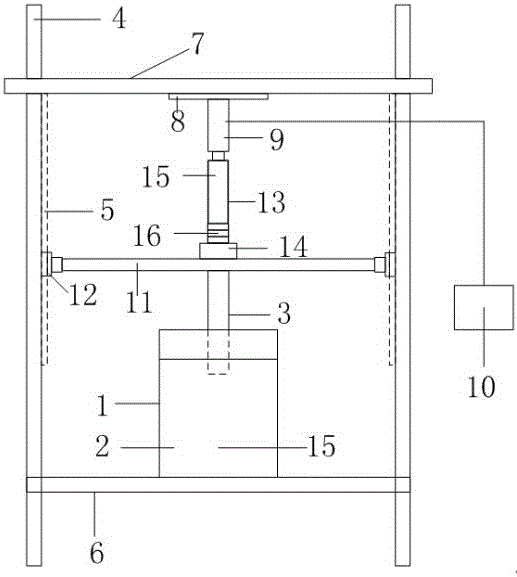

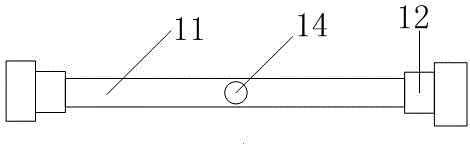

[0015] As shown in the figure, a vertical loading method for simulating the pile sinking process of static pressure piles. Balanced loading reaction frame lower beam 6, self-balancing loading reaction frame upper beam 7, suction cup base 8, microcomputer-controlled electro-hydraulic servo jack 9, loading data controller 10, guide device horizontal slide bar 11, guide device sliding sleeve 12. Open casing 13, fixed base 14, dowel 15, spacer 16; the specific process of vertical loading of the static pressure pile sinking process in the present invention is:

[0016] (1), the model box 1 is placed on the lower beam 5 of the self-balancing loading reaction frame, and the model rod 3 is placed on the surface of the soil body 2 in the model box 1;

[0017] (2) The two ends of the horizontal sliding rod 11 of the guiding device are symmetrically provided with the sliding sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com