A mechanical arm and an excavator including the same

A robotic arm and robotic arm technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc. The bucket oil seal is easily damaged and other problems, so as to reduce the working intensity, improve the effective utilization rate and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will give descriptions of specific embodiments in conjunction with the accompanying drawings of the present invention, but not as any limitation to the present invention.

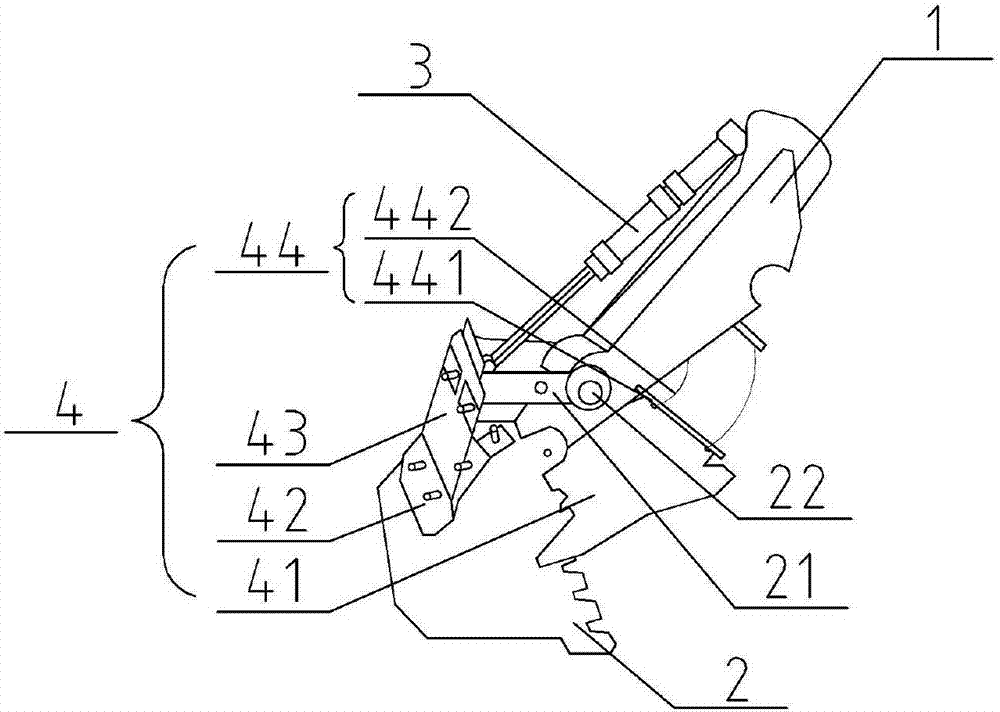

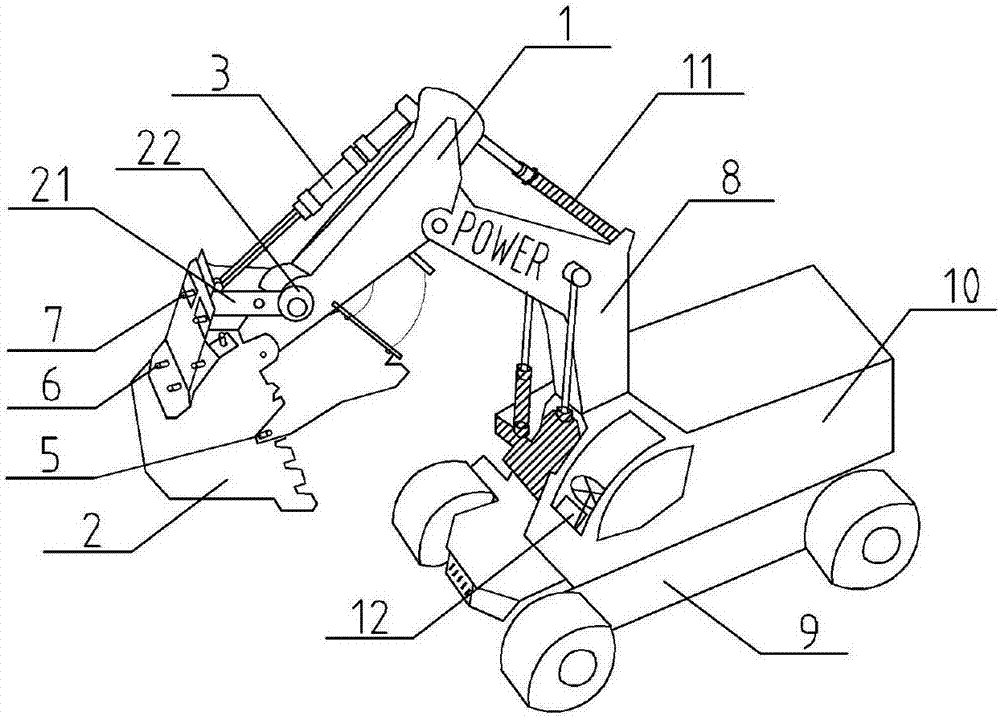

[0036] see Figure 1 ~ Figure 3 , a mechanical arm, including a mechanical arm 1, a bucket 2, a first hydraulic rod 3 and a protective device 4, one end of the mechanical arm 1 is connected to one end of the bucket 2, and the first hydraulic rod 3 One end is connected with one end of the bucket 2 , the other end of the first hydraulic rod 3 is connected with the other end of the mechanical arm 1 , and the protection device 4 is installed on the bucket 2 .

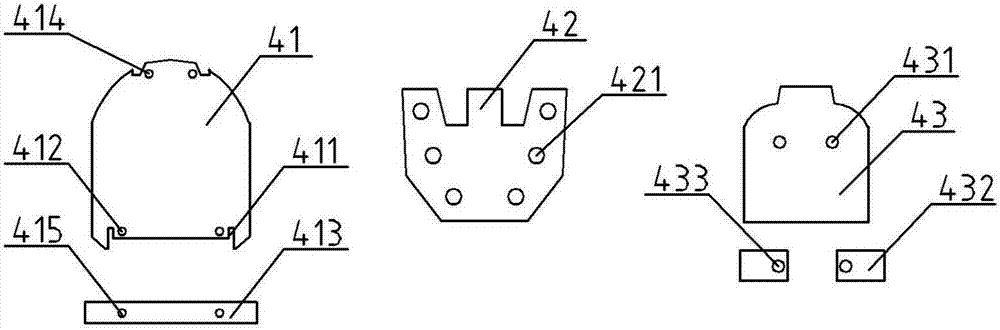

[0037] Further, the guard 4 includes a first guard 41, a second guard 42 and a third guard 43, one end of the first guard 41 is connected to the side wall of the bucket 2, and the other end of the first guard 41 passes through The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com