Oil product circular purifying device based on universal rotary filter

A circulating purification and filter technology, which is applied in the installation/connection of lubricant purification devices, cartridge filters, fixed filter element filters, etc., can solve the problem of non-replaceable filter elements, achieve easy operation and improve operation reliability. The effect of sex, size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

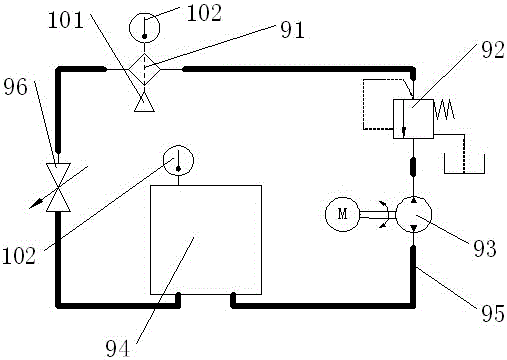

[0042] Such as figure 1 As shown, the oil circulation and purification device based on the general spin-on filter of the present invention includes an oil tank 94, a hydraulic pump 93, a filter 91, a one-way valve 96 and an overflow valve 92 connected by pipelines. The pump 93 sucks the oil that needs to be filtered from the oil tank 94 into the filter 91 and then discharges it into the oil tank 94 through the pipeline; the check valve 96 is used to prevent the oil from flowing back, and the overflow valve 92 is used for pressure in the pipeline. When it is too large, the overflow function is turned on; when the filter is blocked by too many impurities or the pressure difference in the pipeline is too large due to other reasons, the overflow valve 92 is opened to reduce the internal pressure of the pipeline and avoid damage to the system caused by high pressure.

[0043] The filter 91 should use different filter elements according to oil products with different viscosity range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com