Shutter-shaped baffle plate fixed tube-sheet heat exchanger and machining and installing method

A technology of fixed tube-sheet type and baffle plate, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of strict shell-side flow velocity and tube bundle arrangement, complex structure, manufacturing and installation, power equipment High power and other problems, to achieve the effect of good anti-fouling performance, easy assembly, and reduced pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

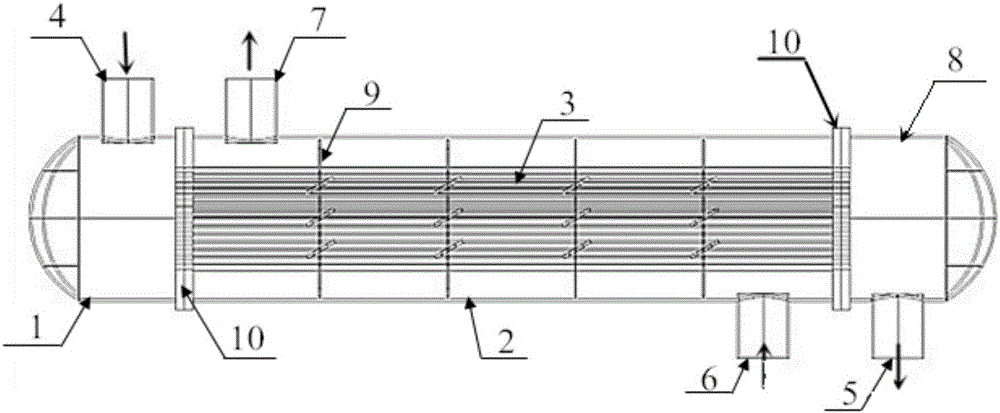

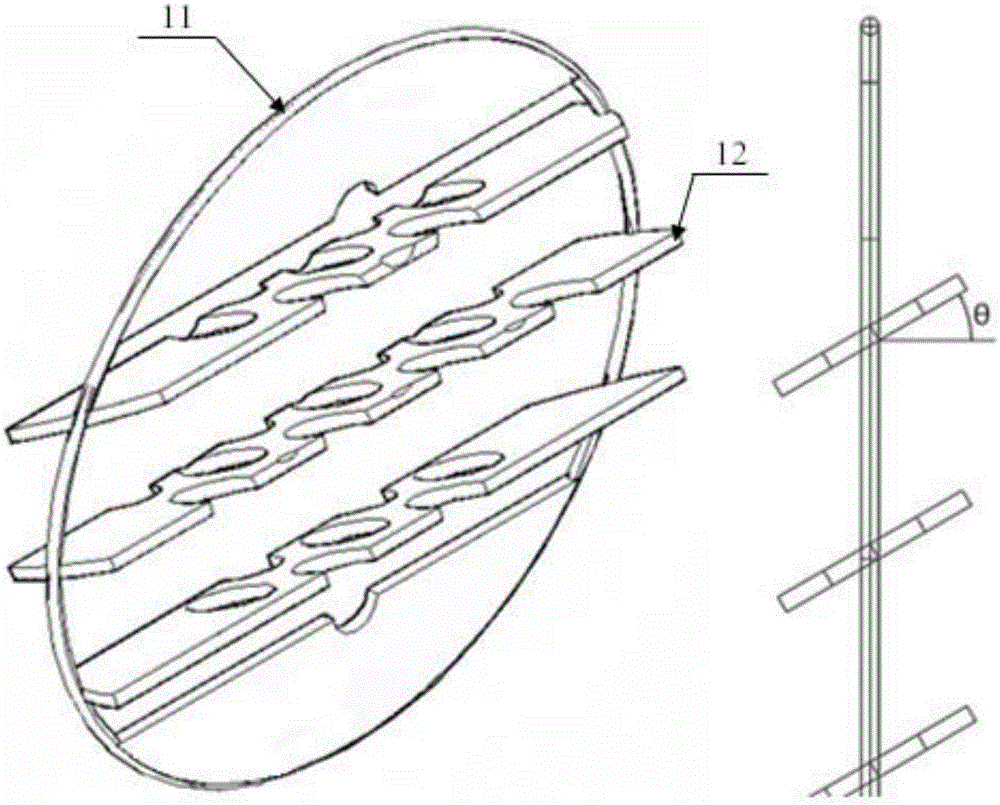

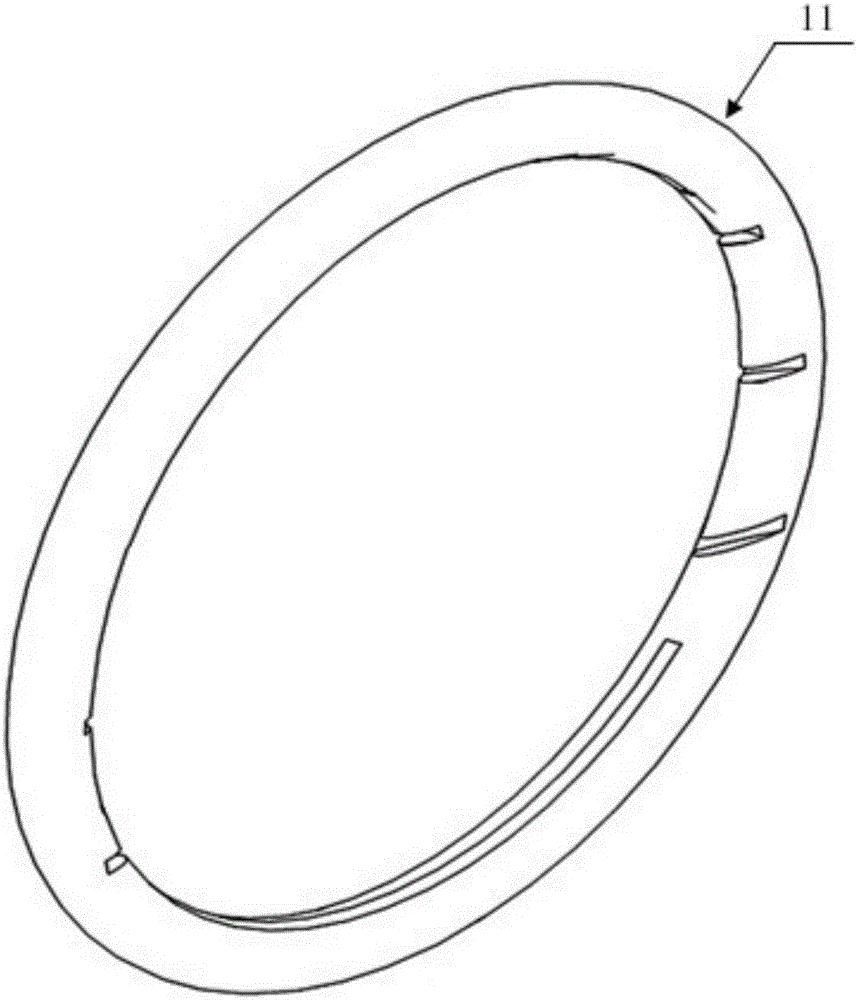

[0042] see figure 1 As shown: the louver-shaped baffle plate fixed tube-sheet heat exchanger of the present invention includes a tube-side inlet tube box 1, a shell 2, a heat exchange tube bundle 3, a tube-side fluid inlet 4, a tube-side fluid outlet 5, and a shell-side fluid Inlet 6, shell side fluid outlet 7, tube side outlet tube box 8, louver-shaped baffle plate 9, tube sheet 10. The tube boxes are located at both ends of the heat exchanger, and the tube-side fluid inlet 4 and the tube-side fluid outlet 5 are welded on the tube-side inlet tube box 1 and the tube-side outlet tube box 8 . The shell-side fluid inlet 6 and the shell-side fluid outlet 7 are welded on the shell 2, and the positions are shown in the figure. The heat exchange tube bundles 3 are inserted into the louver-shaped baffles 9 , and both ends are welded and fixed on the tube sheets 10 . The louver-shaped baffles 9 are welded to the casing 2 equidistantly along the tube axis direction. As shown in the ...

Embodiment approach 2

[0049] The width of each blade is 25% of the shell diameter, the inclination angle θ is 80°, and its thickness is determined jointly by the unsupported span of the heat exchange tube and the nominal diameter of the shell, and the range is 22mm. Others are the same as Embodiment 1.

Embodiment approach 3

[0051] The width of each blade is 20% of the shell diameter, the inclination angle θ is 10°, and its thickness is determined jointly by the unsupported span of the heat exchange tube and the nominal diameter of the shell, and the range is 3mm. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com