Fiber bundle capillary core flat heat pipe and preparation method thereof

A flat heat pipe, capillary core technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of flattening, incomplete structure, low heat transfer efficiency, etc., to achieve tight contact, increase production efficiency, increase steam channel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

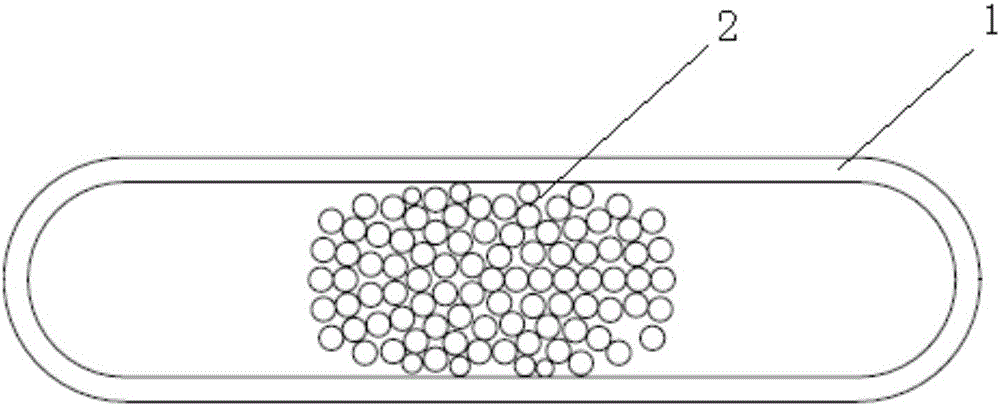

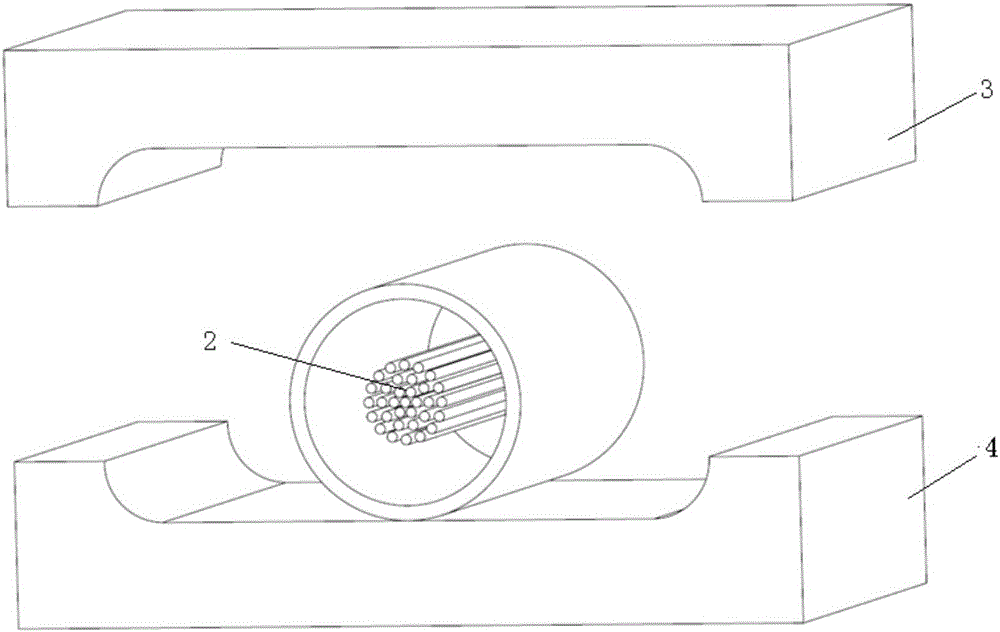

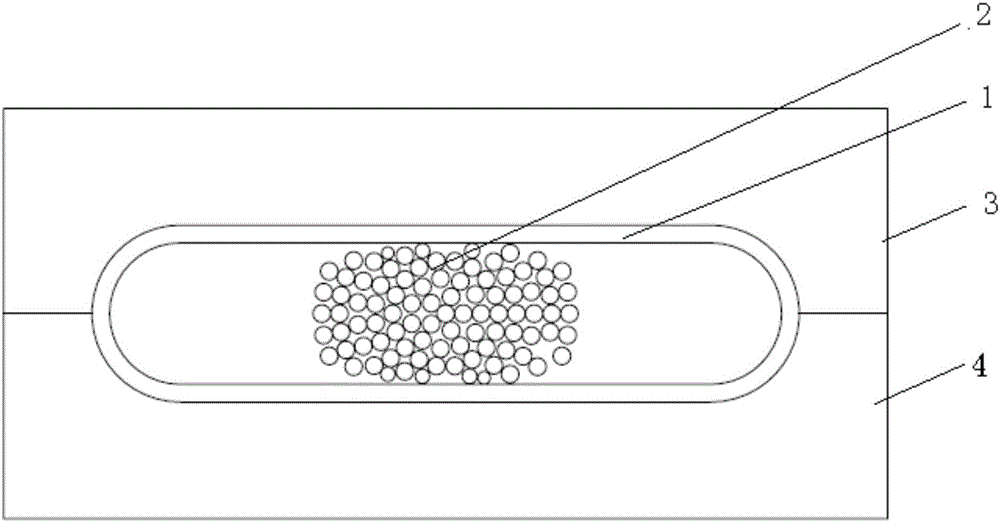

[0024] Such as Figures 1 to 4 shown. The invention discloses a flat heat pipe with a fiber bundle capillary core, which comprises a metal tube 1 with a rounded rectangular cross section and a fiber bundle capillary core 2 fixed inside the metal tube 1; working fluid.

[0025] The rounded rectangular metal tube 1 is molded from a circular metal tube, and the fiber bundle capillary core 2 is in close contact with the inner wall of the metal tube 1 .

[0026] The fiber bundle capillary core 2 is twisted and interwoven with a plurality of copper fibers to form a "twisted" structure. However, a plurality of copper fibers can also be combined in a sintered form, and at this time, the copper fibers do not need to be twisted or interwoven.

[0027] The inner wall of the metal pipe 1 is axially distributed with a plurality of grooves, of course, according to specific process requirements, no grooves may be provided.

[0028] The working liquid is deionized water.

[0029] The met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com