Helical compression spring based break test buffer device for steel wire rope tensile testing machine

A technology of tensile testing machine and buffer device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., and can solve the problems that the tensile testing machine cannot be used normally, the working environment of the testing machine is bad, and the guide screw breaks and other problems, to achieve uniform force, ensure normal operation, and prevent collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

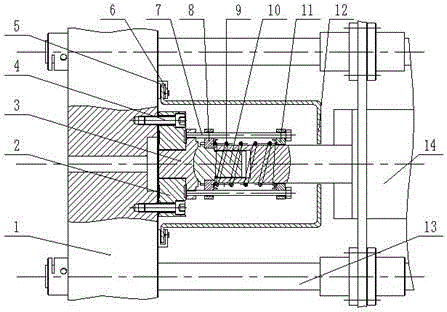

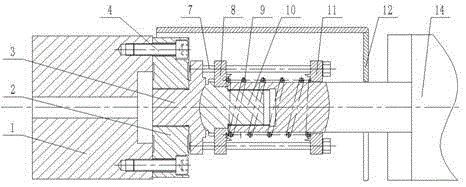

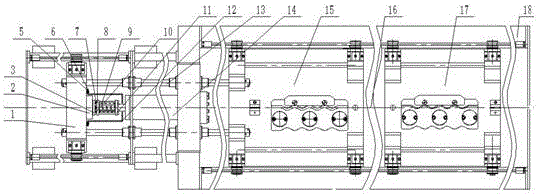

[0016] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , figure 2 , image 3 As shown, a buffer device for breaking test of a wire rope tensile testing machine based on a helical compression spring, the main structure includes a front top beam 1, a sensor 2, a force application seat 3, a guide positioning plate 5, a screw 6, a guide screw 7, and a left pressure plate 8. Spring 9, force application ball head 10, right pressure plate 11, protective cover 12, hydraulic cylinder 14, the sensor 2 is fixed on the front top beam 1 by hexagon socket head screws, the force application ball head 10, force application The force seat 3 is respectively connected to the piston rod of the hydraulic cylinder 14 and the sensor 2 through a threaded structure, and the left pressure plate 8 and the right pressure plate 11 are respectively sleeved on the described force applying ball head 10 and the piston rod of the hydraulic cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com