Single-abrasive-particle continuous scratching testing method for pre-pairing crisp and hard test piece through mutual reference method

A technology of hard and brittle test pieces and single abrasive grains, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problem that the shape accuracy and surface finish of friction discs are very high, and it is impossible to achieve high-speed and high-precision marking of small-grained abrasive grains. Scratch test, unable to maintain a stable contact state between abrasive grains and workpieces, etc., to avoid large end face runout or radial runout, high-speed high-precision scratch test, and solve the effect of poor processing quality

Active Publication Date: 2016-06-29

HUAQIAO UNIVERSITY

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The analysis of a large number of existing documents and published patents found that there are corresponding shortcomings in the four test methods: the scratch speed of the linear scratch test and the wedge surface scratch test is insufficient (the highest linear speed is only 4m/s), and it is difficult to simulate well Abrasive particle processing (maximum linear speed up to 200m/s); the ball-on-disk scratch test method is actually a typical tribological test method. The removal method is very different. When the stable friction stage is reached, there is even no material removal. At the same time, the shape accuracy and surface finish of the friction disc are very high; the single pendulum scratch test is considered to be the closest to the material removal process of abrasive particles. However, the stability of the test is poor. Due to the short contact time between abrasive grains and workpieces, the collection of physical quantities in the material removal process such as cutting force has become a difficult problem.

[0004] Some published patents have pr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Login to view more

Abstract

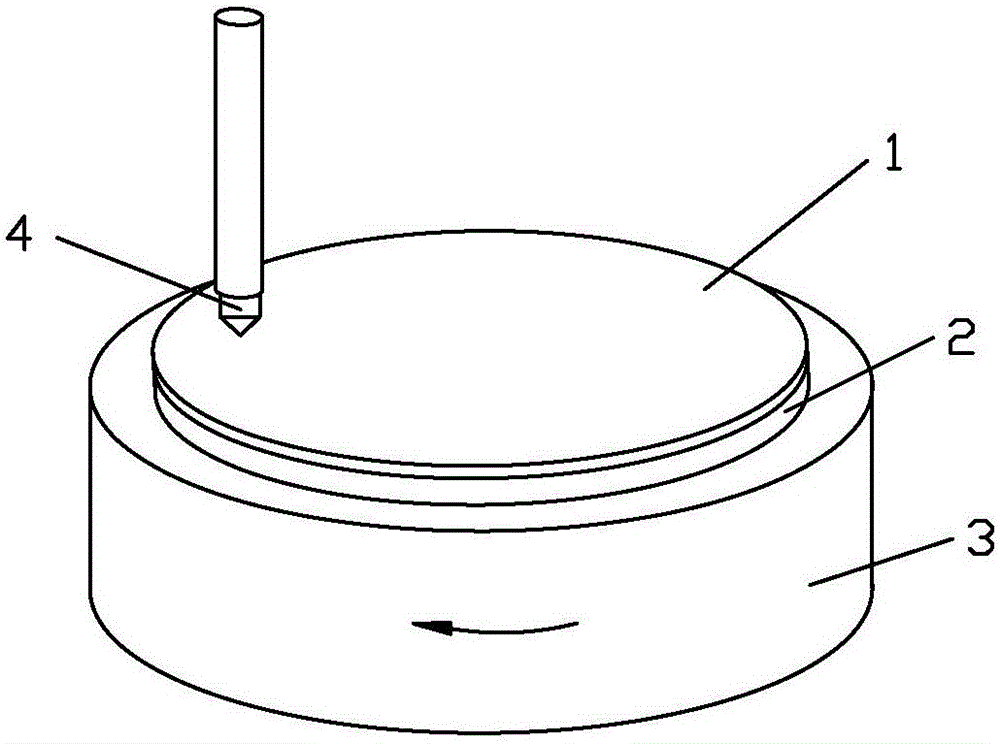

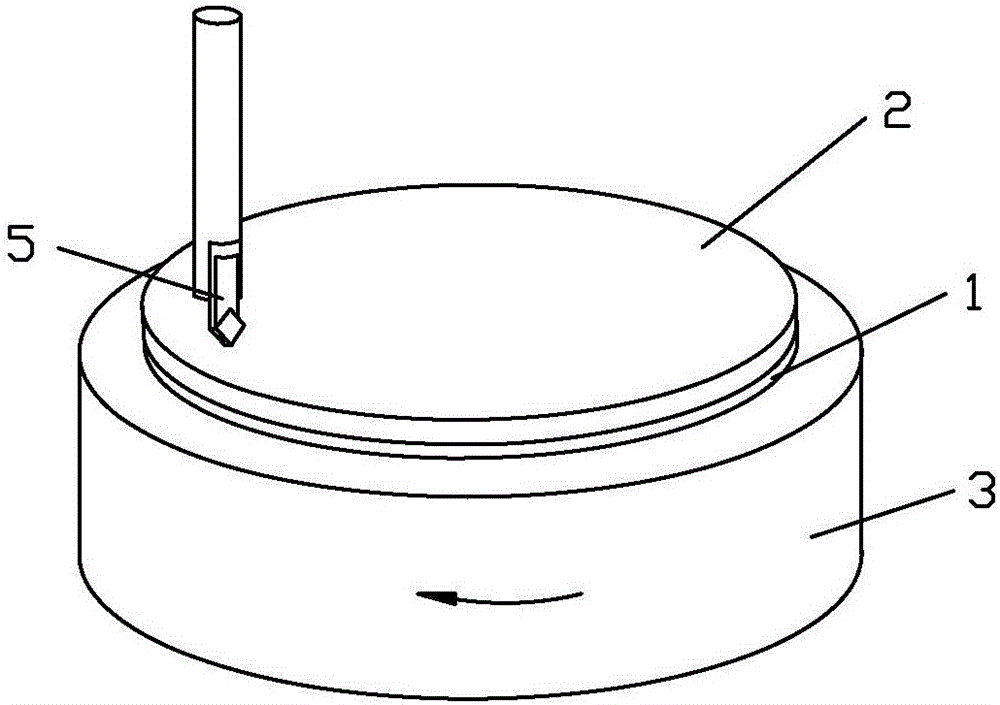

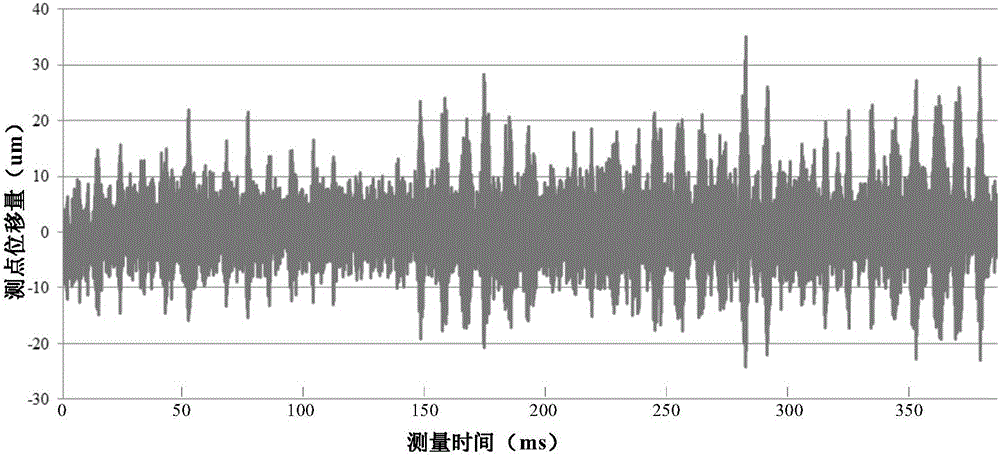

The invention discloses a single-abrasive-particle continuous scratching testing method for pre-pairing a crisp and hard test piece through a mutual reference method, and belongs to the field of material performance testing and precision and ultraprecision machining in machining.The crisp and hard test piece is subjected to backing, the test piece and a backing are treated through the mutual reference method, and the requirement for surface quality and parallelism needed for testing is met; then a tool bit with a single abrasive particle fixedly connected to the top end is reloaded, and tool setting is carried out in the replacing process; finally, scratching testing is carried out, the test piece rotates at specified rotating speed, the tool bit carries out downward cutting to specified cutting depth, the tool bit is fed in the radial direction, a spiral scratch is formed on the end face of the test piece, and a measuring system collects scratching force, acoustic emission signals and other physical quantities in the process.According to the method, stable contact between the abrasive particle and the test piece in a long scratching distance can be guaranteed, high-speed high-precision scratching is achieved, and a relevant testing result can be used for study on the material removal mechanism in the friction wear process and the abrasive machining process.

Description

technical field [0001] The invention belongs to the field of material performance testing and precision and ultra-precision machining in mechanical processing, and in particular relates to a single abrasive particle continuous scratching test method for pre-repairing hard and brittle test pieces with a mutual reference method. Background technique [0002] The abrasive grain processing process can be regarded as a cutting process completed by a large number of abrasive grains of various shapes that are unevenly arranged and irregularly distributed on the surface of the abrasive tool. In scientific research, complex phenomena are often abstracted into a simplified model to explore some of the most essential issues. The cutting action of fine abrasive grains is the basis of grinding process. As the basic mode of grinding process, the scratching, plowing and cutting of single abrasive grains have become an important means to understand the complex grinding action. [0003] The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G01N19/06

CPCG01N19/06

Inventor 姜峰张涛言兰徐西鹏

Owner HUAQIAO UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap