Bar counting method based on machine vision

A technology of machine vision and counting method, applied in instruments, computing, image data processing, etc., to reduce costs, improve accuracy, and improve accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

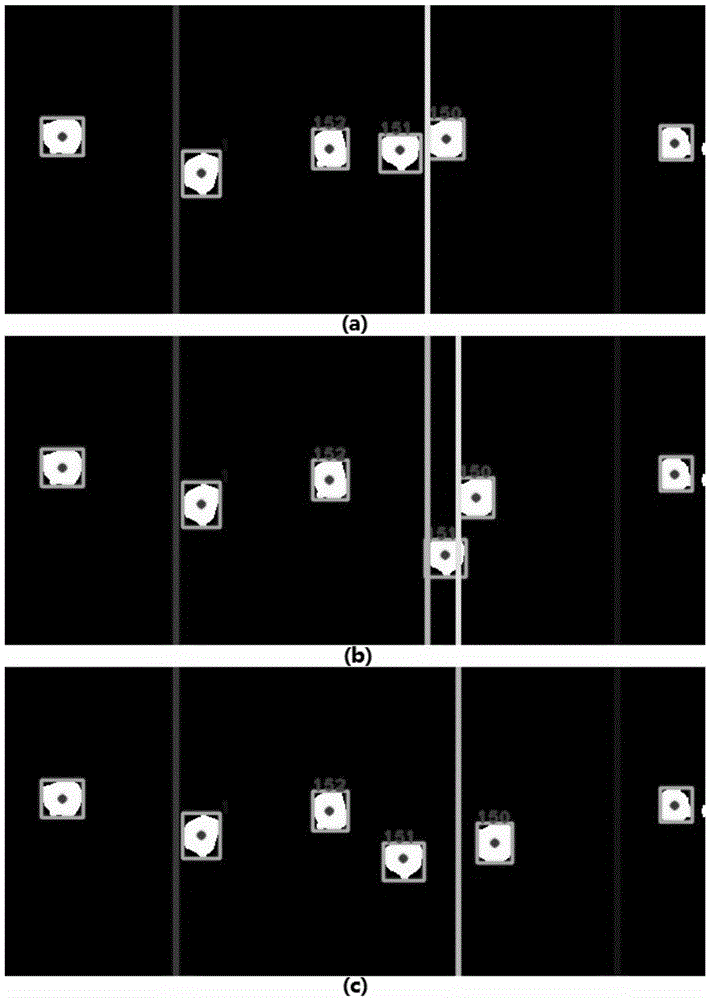

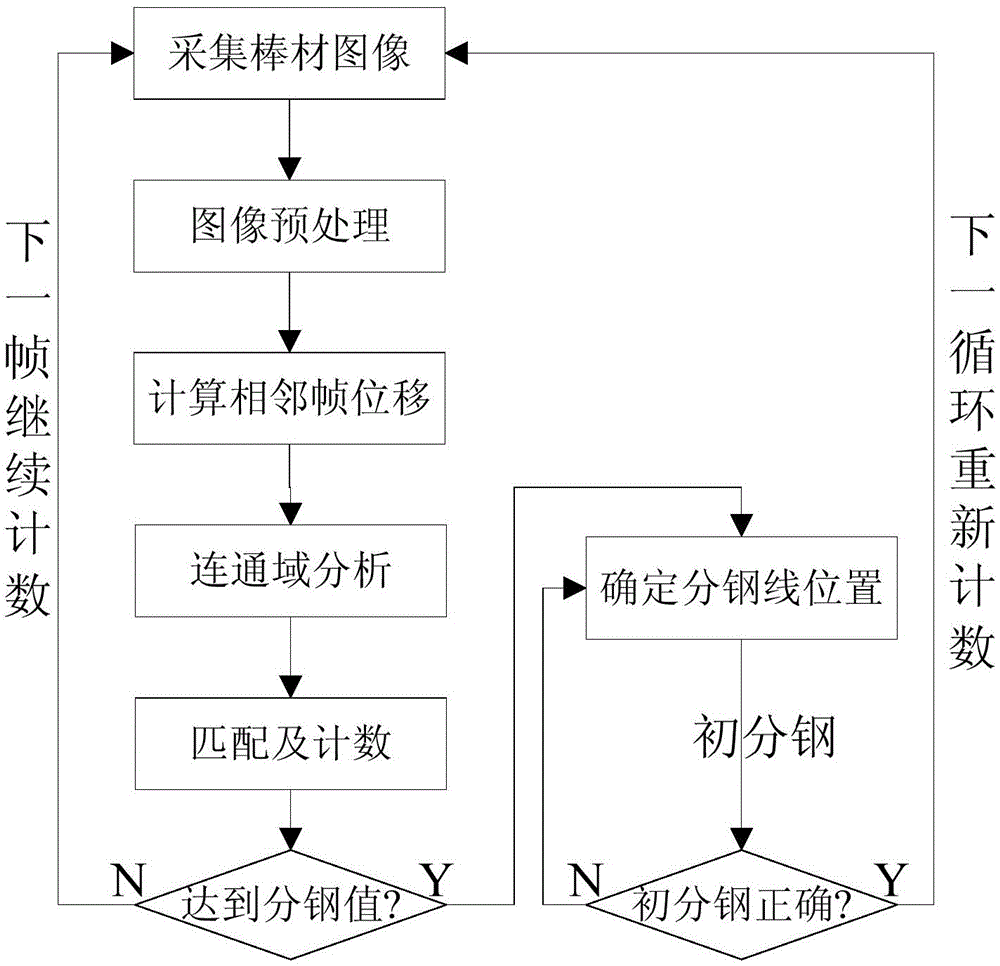

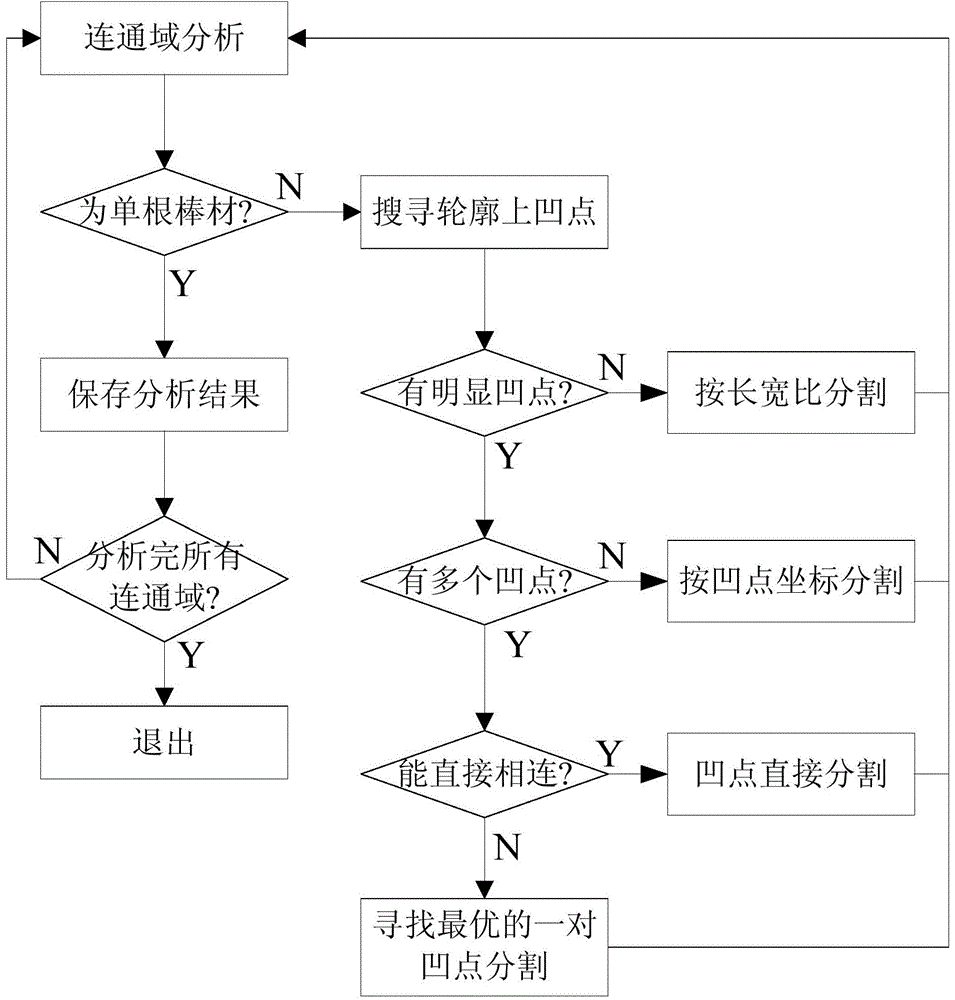

[0038] figure 1 It is the overall flow chart of the present invention, including collecting bar images, preprocessing the images such as smoothing, binarization, and morphological operations, calculating the relative displacement of the bars, performing connected domain analysis on the bars, and connecting the bars with the previous frame. Material comparison and matching counting, if the count value has not yet reached the number of steel points, the above operation counting will continue in the next frame until the count value reaches the number of steel points, control the conveyor chain to stop, and determine the position of the steel line, control the steel machine to carry out After the initial steel division, judge whether the result of the initial steel division is correct. If it is not correct, the initial steel division will be carried out again. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com