Prediction method for corrosion rate of Q235 galvanized steel grounding net of transformer station

A prediction method and corrosion rate technology, applied in the field of power systems, can solve problems such as inconvenient detection methods, hidden dangers of equipment safe operation, and degradation of grounding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

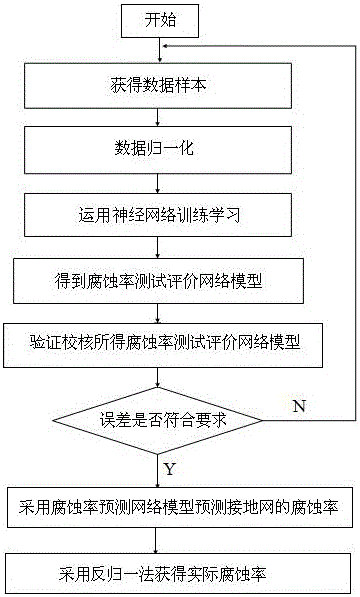

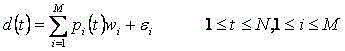

Method used

Image

Examples

Embodiment 1

[0055] In the present embodiment, step C adopts RBF neural network to carry out training and learning, and specifically includes the following steps:

[0056] C11. Determine the Spread value.

[0057] The size of the Spread value in the RBF neural network model is determined by numerical heuristics. The specific process is to first try in the range of [1, 100], and the interval of each trial is 5, and then the average value of the network operation results can be determined. The change of the square error selects the Spread value with the best prediction performance of the model at the end. After tentative comparison, when the Spread value is equal to 20, the average relative error of the network is the smallest, and the mean square error is not the largest among the nearby values. Therefore, in this embodiment, it is most appropriate to set the Spread value of the RBF network model to 20.

[0058] C12. Use the training and learning of the RBF neural network, find out the st...

Embodiment 2

[0069] In the present embodiment, step C adopts BP neural network for training and learning, which specifically includes the following steps:

[0070] C21. Use LM algorithm to train BP neural network.

[0071] C22. Determine the number of layers of the BP neural network.

[0072] In the BP neural network model, the number of neurons in the input layer and output layer of the sample data is initially determined, so relatively speaking, the neurons in the hidden layer are uncertain. From the perspective of data processing in this embodiment, a neural network composed of a hidden layer can meet the specified accuracy requirements, so the number of layers of the neural network model established below is 3, which are 1 input layer, 1 hidden layer and 1 output layer.

[0073] C23. Determine the number of nodes in the input layer and output layer.

[0074] The network prediction model constructed in this example has 6 input factors, that is, 6 factors of soil physical and chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com