Roller assembly for transmitting after stranding of multiple copper stranded wires

A rolling and twisting technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of copper strand tension reduction, stress concentration, copper strand relaxation, etc., and achieve the effect of avoiding jumping and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

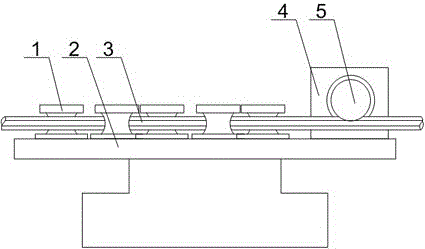

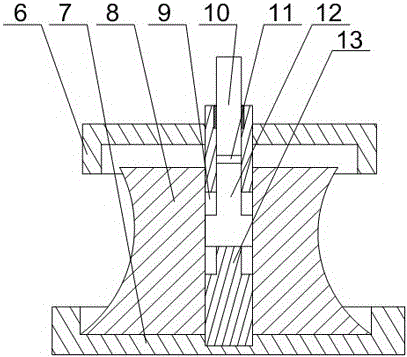

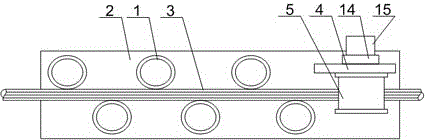

[0024] Such as Figure 1~Figure 4 As shown, this embodiment includes a workbench 2 and two rows of staggered side pressure rollers 1 installed on the workbench 2. A support plate 4 is also arranged on the workbench 2. The side pressure rollers 1 Including an upper end cover 6, a side pressure cylinder 8 and a lower end cover 7, a column 13 is set in the middle of the lower end cover 7, the upper end of the column 13 runs through the upper end cover 6, and the side pressure cylinder 8, which is concave inward in the middle, is sleeved on the column 13 Above, the upper end surface of the side pressure cylinder 8 and the upper end cover 6 have a horizontal through hole 9 in the middle along the radial direction of the column 13, and an adjustment hole communicating with the horizontal through hole 9 is opened in the upper section along the axial direction of the column 13. A T-shaped block 12 is installed in the hole 9, and both sides of the horizontal section of the T-shaped blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com