A funnel-shaped film hole structure for turbine blades

A technology of turbine blades and air film holes, which is applied in the direction of supporting components of blades, machines/engines, mechanical equipment, etc., can solve the problems of difficult processing of special-shaped holes and high cost, and achieve improved air film cooling efficiency, low cost, and centrifugal force weakened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

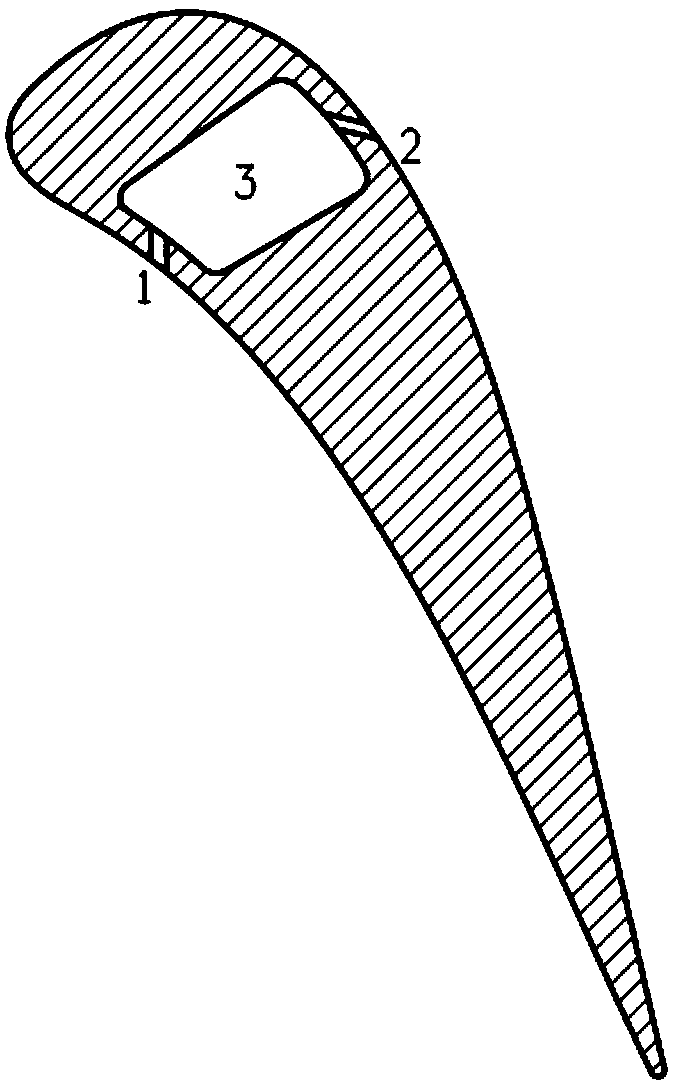

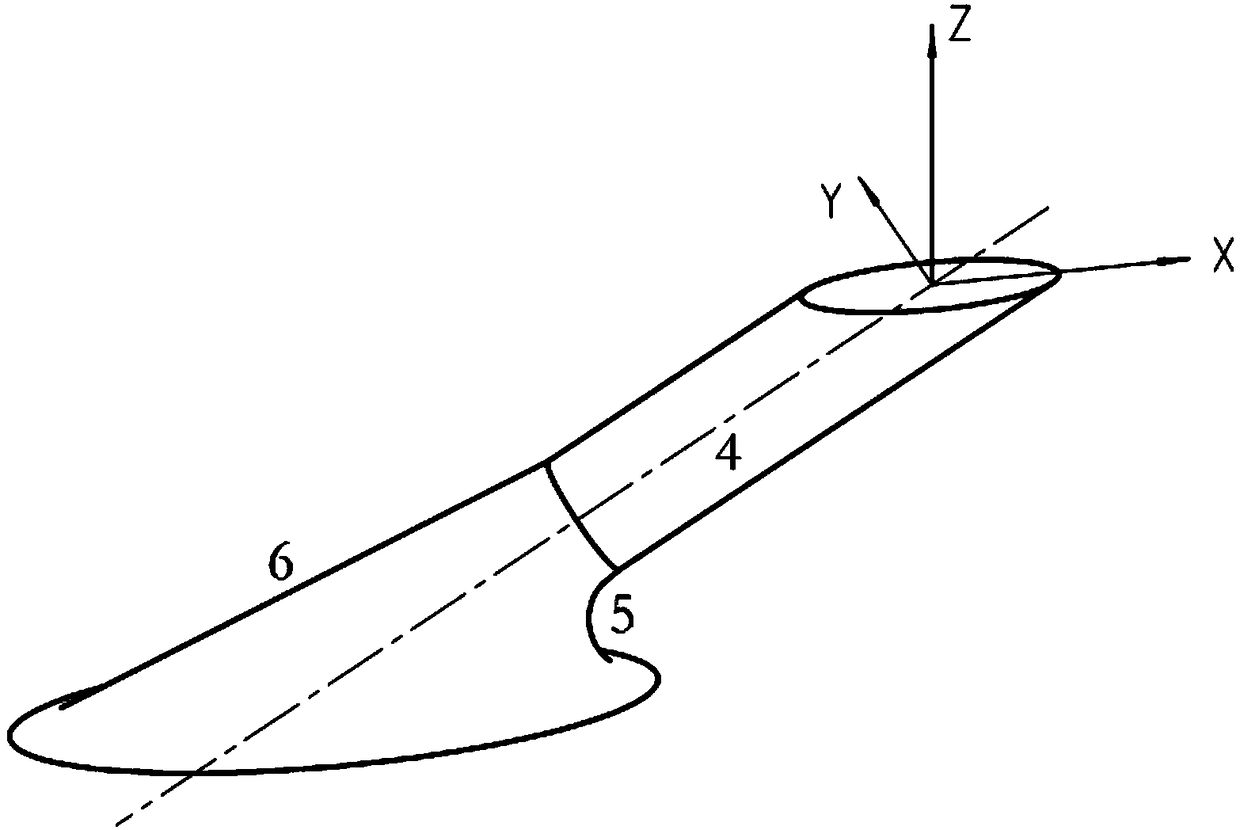

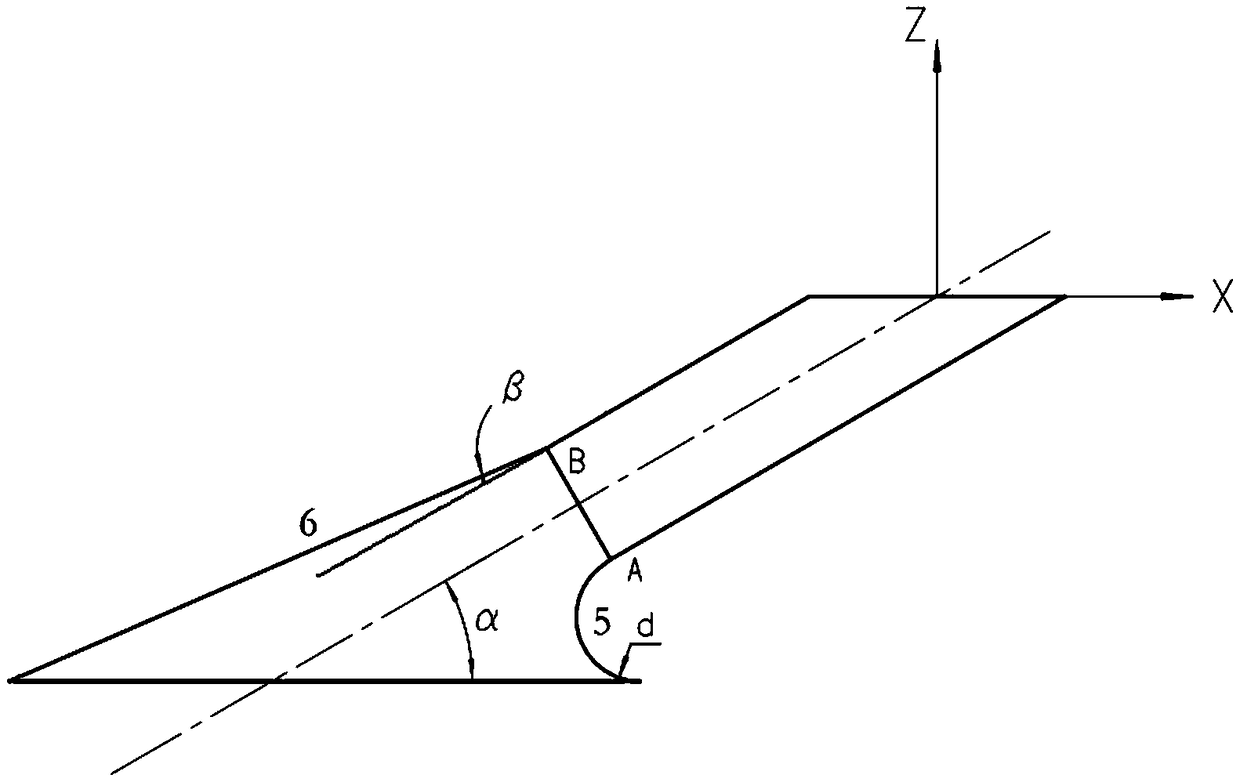

[0024] This embodiment is a funnel-shaped air film hole structure applied to a certain type of turbine blade. The funnel-shaped air film hole 1 on the pressure surface and the funnel-shaped air film hole 2 on the suction surface are respectively arranged on the turbine blade. The two ends of the film hole 1 and the funnel-shaped air film hole 2 on the suction surface respectively form the outlet and the inlet of the airflow, and communicate with the cooling channel 3 in the blade for air supply. The entrance of the inclined cylindrical air film hole 4 is enlarged, the lower wall surface of the inclined cylindrical air film hole inlet is rounded to form an expanded profile, and the upper wall surface of the inclined cylindrical air film hole inlet is expanded into a conical profile surface through conical expansion. The inclination angle α of the inclined cylindrical air film hole 4 is 30°, and the diameter D of the inclined cylindrical air film hole 4 is 2mm. The rounded diame...

Embodiment 2

[0027] This embodiment is a funnel-shaped air film hole structure applied to a certain type of turbine blade. The funnel-shaped air film hole 1 on the pressure surface and the funnel-shaped air film hole 2 on the suction surface are respectively arranged on the turbine blade. The two ends of the film hole 1 and the funnel-shaped air film hole 2 on the suction surface respectively form the outlet and the inlet of the airflow, and communicate with the cooling channel 3 in the blade for air supply. The entrance of the inclined cylindrical air film hole 4 is enlarged, the lower wall surface of the inclined cylindrical air film hole inlet is rounded to form an expanded profile, and the upper wall surface of the inclined cylindrical air film hole inlet is expanded into a conical profile surface through conical expansion. The inclination angle α of the inclined cylindrical air film hole 4 is 45°, and the diameter D of the inclined cylindrical air film hole 4 is 1mm. The diameter of t...

Embodiment 3

[0030]This embodiment is a funnel-shaped air film hole structure applied to a certain type of turbine blade. The funnel-shaped air film hole 1 on the pressure surface and the funnel-shaped air film hole 2 on the suction surface are respectively arranged on the turbine blade. The two ends of the film hole 1 and the funnel-shaped air film hole 2 on the suction surface respectively form the outlet and the inlet of the airflow, and communicate with the cooling channel 3 in the blade for air supply. The inlet of the inclined cylindrical air film hole 4 is enlarged, the lower wall surface of the inclined cylindrical air film hole inlet is rounded to form an expanded profile, and the upper wall surface of the inclined cylindrical air film hole inlet is expanded into a conical shaped surface through conical expansion. The inclination angle α of the inclined cylindrical air film hole 4 is 60°, and the diameter D of the inclined cylindrical air film hole 4 is 0.3 mm. The diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com