Tension adjusting assembly for stranding machine outlet

A tension adjustment and stranding machine technology, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of reduced copper strand tension, stress concentration, uneven distribution of copper strands, etc., to avoid damage, avoid bouncing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

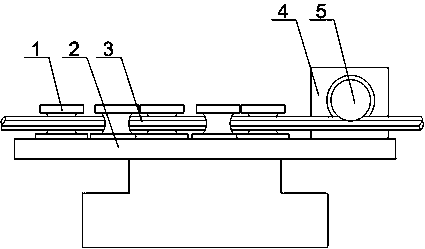

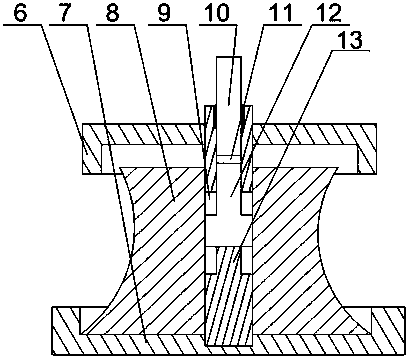

[0020] like figure 1 and figure 2 As shown, this embodiment includes a workbench 2 and two rows of side pressing rollers 1 arranged on the workbench 2 in a staggered manner. The workbench 2 is also provided with a support plate 4, and the pressing rollers 5 are rotated and arranged On the support plate 4 , the side pressure roller 1 includes an upper end cover 6 , a side pressure cylinder 8 and a lower end cover 7 , a column 13 is arranged in the middle of the lower end cover 7 , the upper end of the column 13 penetrates the upper end cover 6 , and the middle part faces The inner recessed side pressure cylinder 8 is sleeved on the column 13, the upper end surface of the side pressure cylinder 8 and the upper end cover 6 are provided with a horizontal through hole 9 in the middle along the radial direction of the column 13, and a horizontal through hole 9 is opened in the upper section along the axial direction of the column 13. The adjustment hole communicated with the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com