Compactly-assembled temperature controller

A temperature controller, compact technology, applied in the direction of thermal switch parts, etc., can solve the problems of high resistance and electric strength, and achieve the effect of compressing the overall structure height, compact layout and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

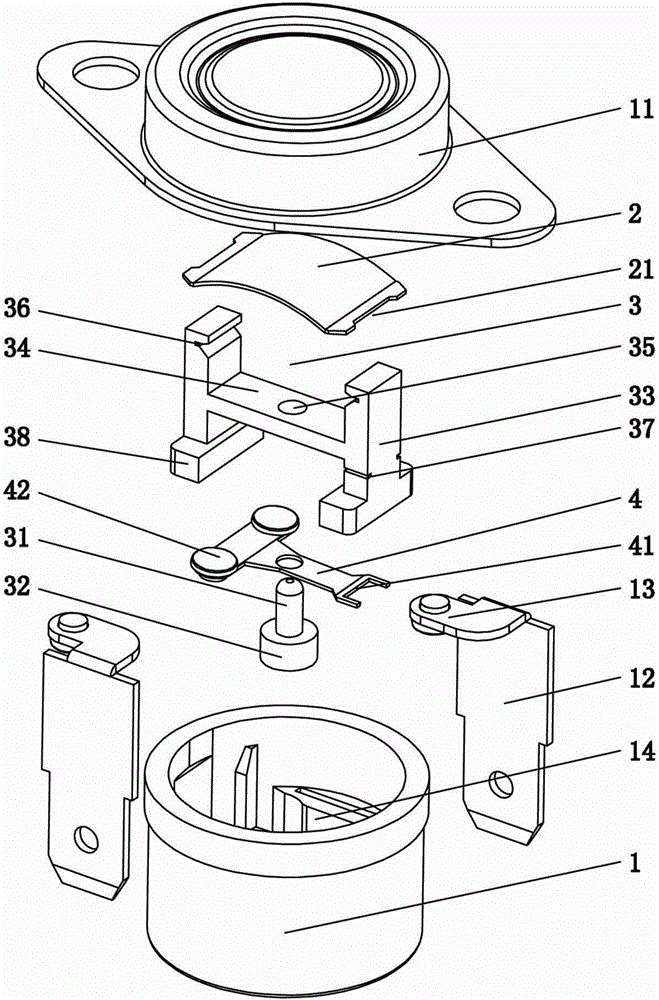

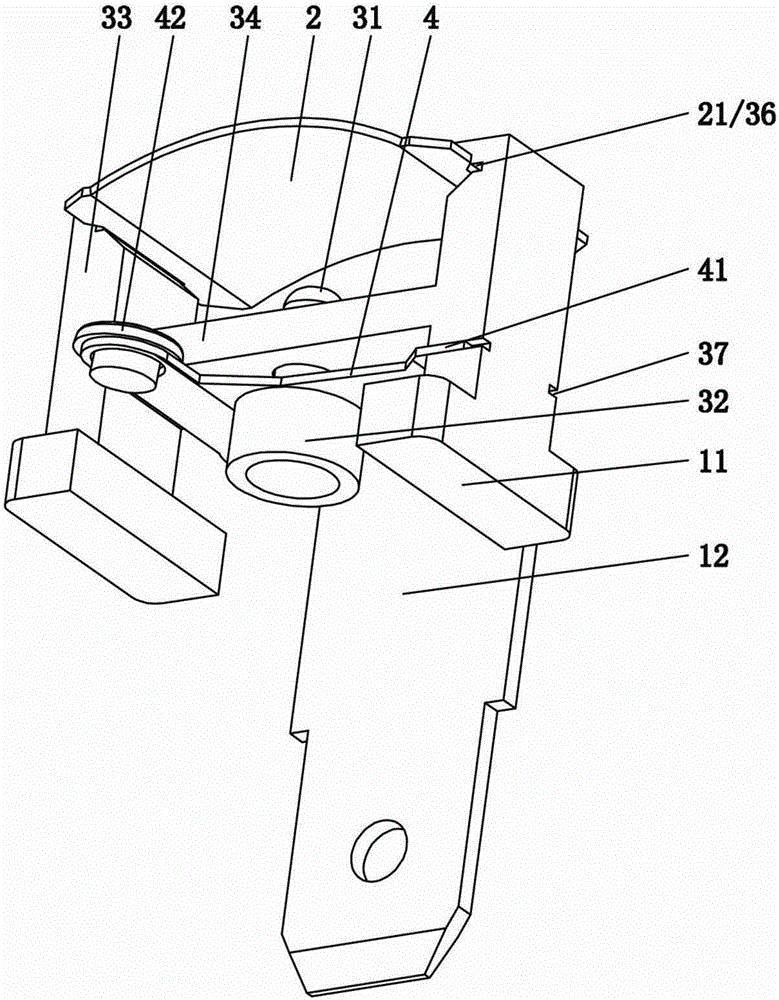

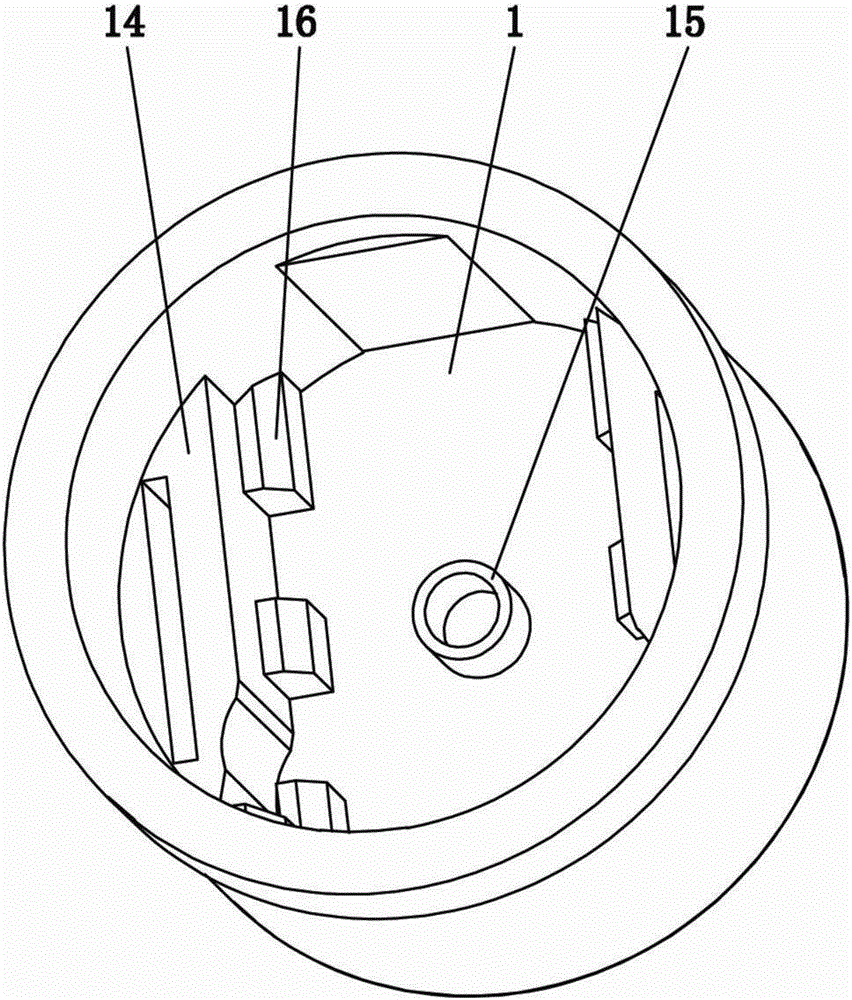

[0019] Such as figure 1 As shown, a compact assembly thermostat according to the present invention includes a housing 1 with an open upper end, a temperature sensing cover 11 is provided on the upper port of the housing 1, and two electrical terminals are provided on the bottom plate of the housing 1 12. The housing 1 is provided with a heat-sensitive sheet 2 and an action mechanism. The action mechanism includes a bracket 3. The heat-sensitive sheet 2 is horizontally fixed on the upper end of the bracket 3 and is in conflict with the temperature-sensitive cover 11. The bracket 3 is vertically provided with a movable plunger 31, and the upper end of the movable plunger 31 is correspondingly arranged in the deformation zone below the heat-sensitive sheet 2, and the elastic shift fork 4 is arranged on the support 3, and the fixed end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com